Tight fitted aluminum housing and cover plate for lithium ion battery

A lithium-ion battery, tight fit technology, applied in the direction of battery cover/end cover, secondary battery, battery pack components, etc., can solve problems such as insufficient fit, waste of raw materials, loss, etc., to increase contact area and force direction, increasing welding yield and reducing material cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

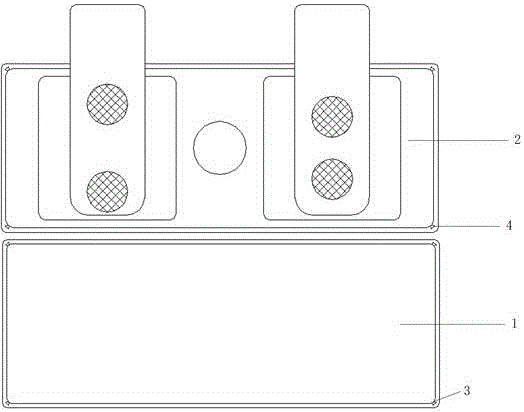

[0014] A close-fit aluminum case and cover plate for lithium-ion batteries, including an aluminum case 1 and a cover plate 2, grooves 3 are provided at the four corners inside the aluminum case 1, and grooves 3 are provided at the four corners of the cover plate 2. There are protrusions 4, the protrusions 4 and the grooves 3 are equilateral trapezoidal right quadrangle structure, the protrusions 4 and the grooves 3 cooperate; the cover plate 2 and the protrusions 4 are integrally formed by injection molding. In this way, when the cover plate 2 and the aluminum shell 1 are matched together, in addition to the common chamfering fit, a concave-convex structure is added, which improves the fit between the cover plate 2 and the aluminum shell 1, and increases the aluminum shell 1 and the cover plate 2. High welding yield, improve production efficiency. The protrusion 2 is the positioning pin, and the groove 3 is the pin hole. Based on the tolerance grade IT6 of the processed part, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com