A simulation system for simulating fracture healing process

A simulation system and fracture healing technology, applied in the field of biomedical engineering, can solve the problems that mechanical factors do not have a deterministic relationship in cell differentiation, do not consider changes in the shape and size of callus, and the settings of models and biological materials are too simplified. Achieve the effect of avoiding humanitarian disputes, reducing biological experiments, and reducing delayed healing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

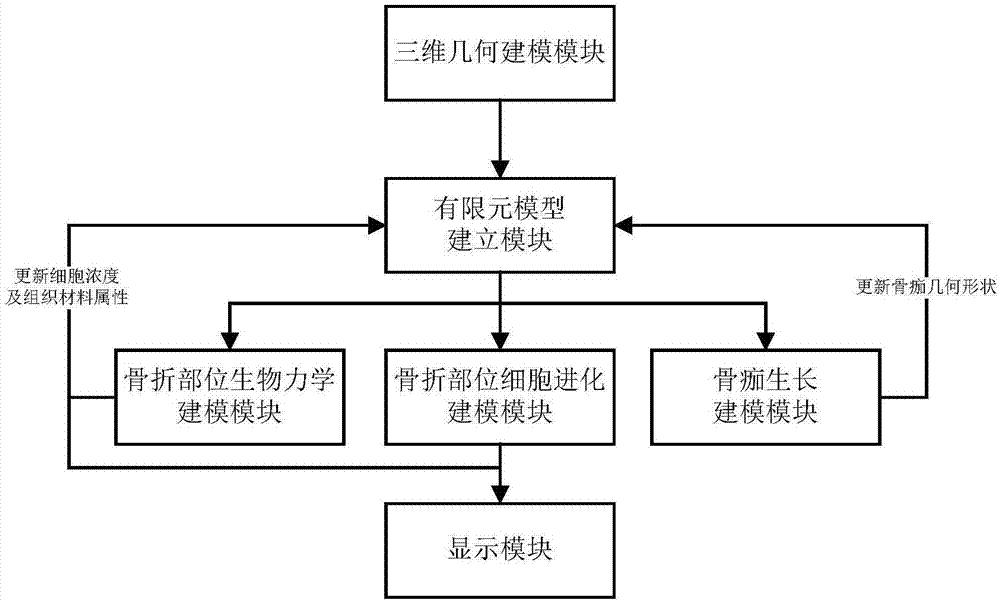

[0030] Specific implementation mode one: as figure 1 As shown, a simulation system for simulating the fracture healing process described in this embodiment includes: a three-dimensional geometric modeling module for fracture parts, a finite element modeling module for fracture parts, a biomechanical modeling module for fracture parts, and a cell evolution modeling module for fracture parts module, callus growth modeling module and display module;

[0031] The three-dimensional geometric modeling module of the fracture site is used to establish a three-dimensional surface geometric model of the fracture site after image preprocessing according to the imported two-dimensional tomographic image data;

[0032] The finite element modeling module of the fracture site is used for meshing the obtained three-dimensional surface geometric model of the fracture site, realizing the discretization of the continuous three-dimensional geometric model, and obtaining node coordinates and unit ...

specific Embodiment approach 2

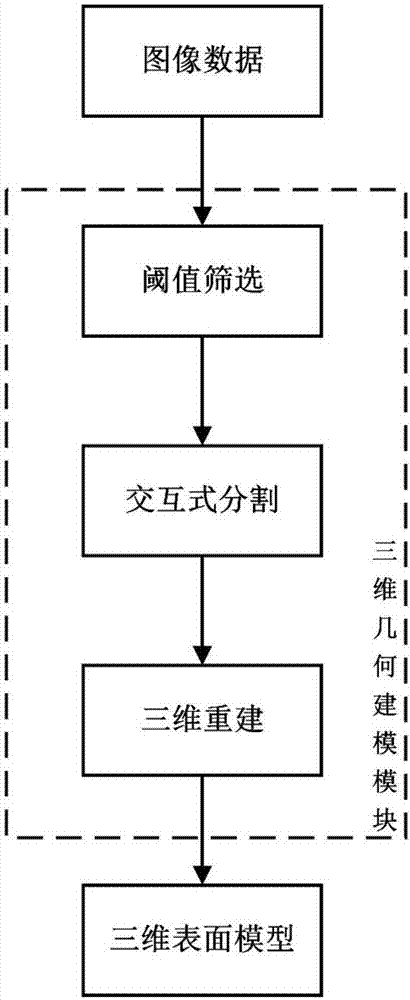

[0037] Specific implementation mode two: as figure 2 As shown, in this embodiment, the specific process of the three-dimensional geometric modeling module of the fracture site to realize its function is:

[0038] Using the segmentation-based 3D medical image surface reconstruction algorithm to reconstruct the 3D surface of the image, and obtain the 3D surface geometric model through the process of threshold screening, interactive segmentation and 3D reconstruction;

[0039] The image is obtained by imaging equipment CT, and the data storage format is DICOM.

[0040] Other components and connections of this embodiment are the same as those of Embodiment 1.

specific Embodiment approach 3

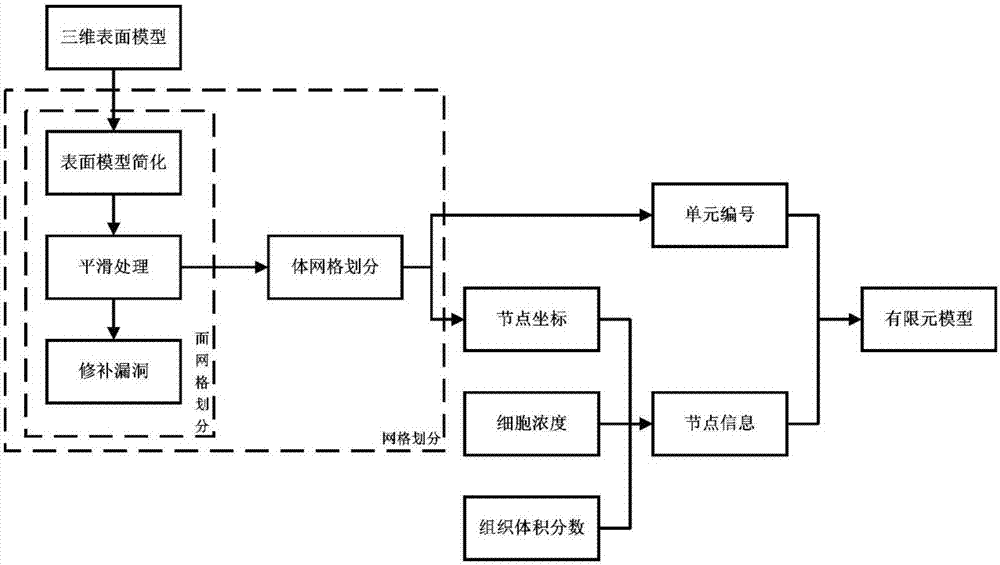

[0041] Specific implementation mode three: as image 3 As shown, in this embodiment, the specific process of the fracture site finite element modeling module to realize its function is as follows:

[0042] The established three-dimensional surface geometric model is meshed, the continuous three-dimensional geometric model is discretized, and the node coordinates and unit numbers are obtained; the cell concentration and tissue volume fraction are stored in the unit nodes, and together with the node coordinates constitute the node information; Node information and element numbers form the required three-dimensional finite element model of the fracture site;

[0043] The meshing includes two steps of surface meshing and volume meshing; the surface meshing process is used to optimize the three-dimensional surface model, including: surface model optimization, smoothing, repairing loopholes; surface model optimization It is realized by reducing the triangular surface of the surface...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com