Design method of embedded type anti-slide piles

A design method and anti-sliding pile technology, applied in design optimization/simulation, calculation, special data processing application, etc., can solve the problem that design parameters cannot be calculated, and achieve the effect of simple solution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

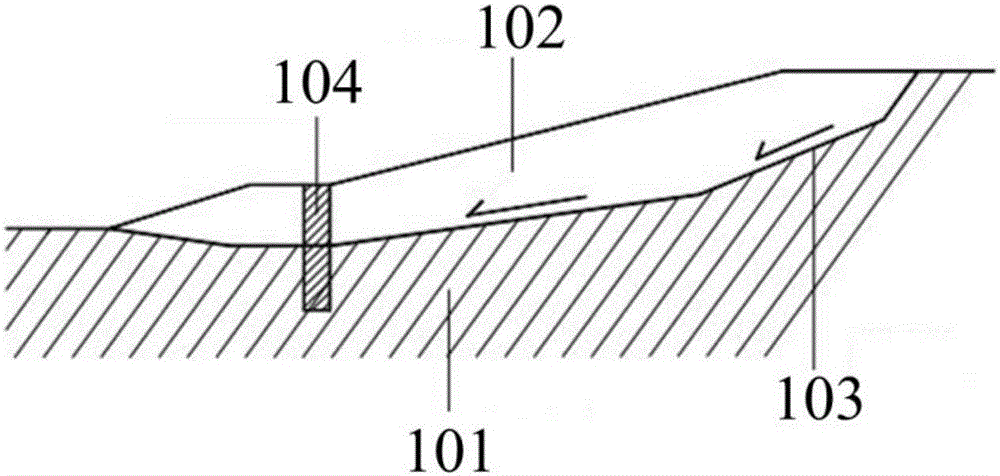

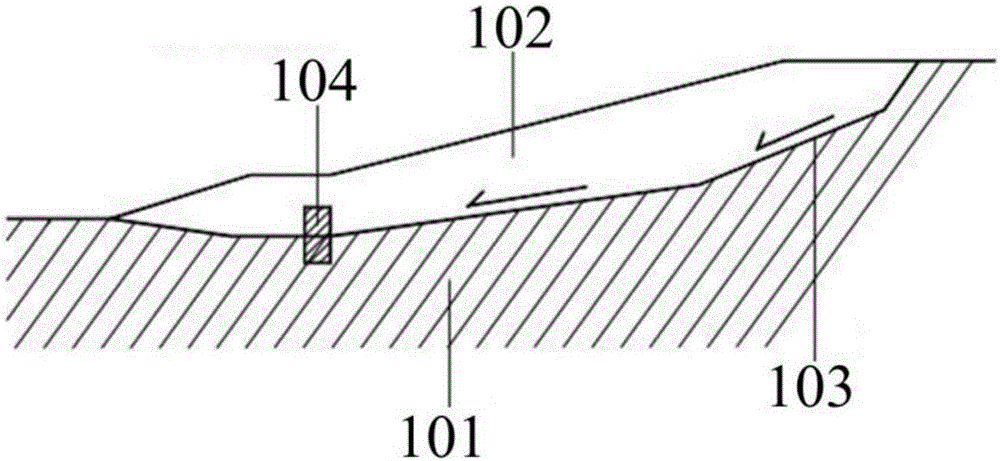

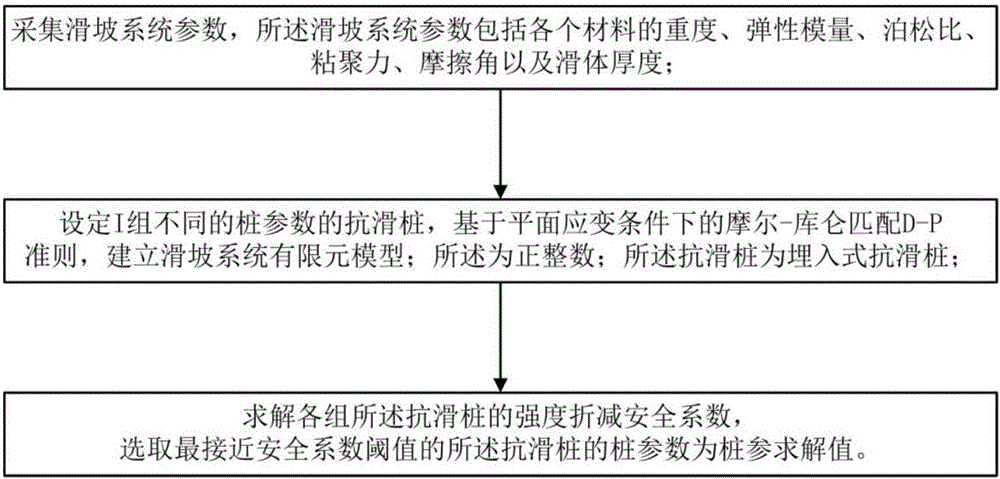

[0048] Such as Figure 3-10 As shown, the present invention provides a design method of embedded anti-slide pile 104, comprising the following steps:

[0049] S1, collecting landslide system parameters, said landslide system parameters include the severity γ, modulus of elasticity E, Poisson’s ratio ν, cohesion c, friction angle of each material And the thickness H of the sliding body 102;

[0050] S2, setting the anti-slide pile 104 of different pile parameters of I group, based on the Moore-Coulomb matching D-P criterion under the plane strain condition, establishes the landslide system finite element model; Described I is a positive integer; Described anti-slide pile 104 is Embedded anti-slide pile 104;

[0051] S3, solving the strength reduction safety factor S of the anti-slide pile 104 of each group i, select the closest safety factor threshold S ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com