Aero-engine high pressure turbine disc optimization design system based on particle swarm and method

An aero-engine and high-pressure turbine technology, which is used in design optimization/simulation, calculation, special data processing applications, etc., and can solve the problems of large calculation granularity of grid crowding degree, inability to reflect the characteristics of file distribution, and easy loss of boundaries and non-inferior solutions. , to ensure uniformity and diversity, avoid random abandonment, and achieve the effect of accurate grid positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0054] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

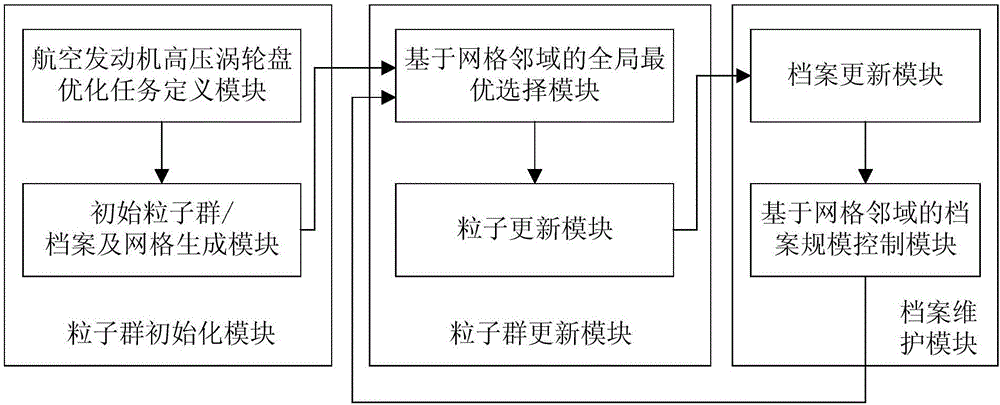

[0055] Such as figure 1 As shown, the present embodiment provides a particle swarm-based high-pressure turbine disk optimization design system for aero-engines, which includes a particle swarm initialization module, a particle swarm update module, and a file maintenance module for aero-engine high-pressure turbine disks. The final file obtained is Multi-objective optimization results.

[0056] The aero-engine high-pressure turbine disk particle swarm initialization module includes an aero-engine high-pressure turbine disk optimization task definition module and an initial particle swarm / file and grid generation module.

[0057] The aero-engine high-pressure turbine disk ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com