Characterization method of nonlinear seepage characteristics of single-phase fluid through low-permeability core

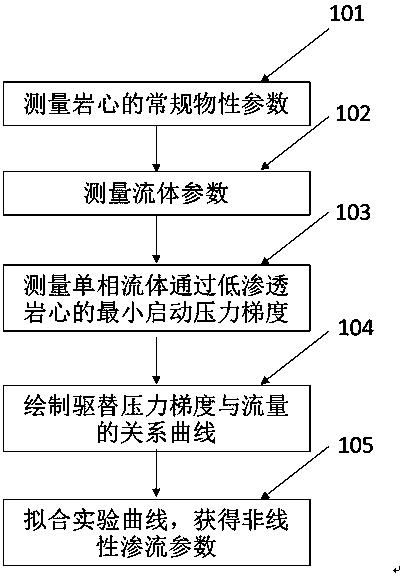

A low-permeability, nonlinear technology, applied in the field of characterization of nonlinear seepage characteristics, can solve the problems of not being able to simultaneously characterize fluid starting pressure gradient and nonlinear flow characteristics, unclear physical meaning of model parameters, and difficulty in obtaining parameters

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] In step 1, the conventional basic parameters of the core used in the experiment: the core length is 52mm, the diameter is 25mm, the porosity is 0.09, and the permeability is 1.5mD.

[0031] In step 2, the simulated oil parameters for the experiment: the simulated viscosity is 2mPa / s, and the volume coefficient is 1.1.

[0032] In step 3, the static method is used to measure and simulate the minimum starting pressure gradient through the low permeability core as 0.006MPa / m.

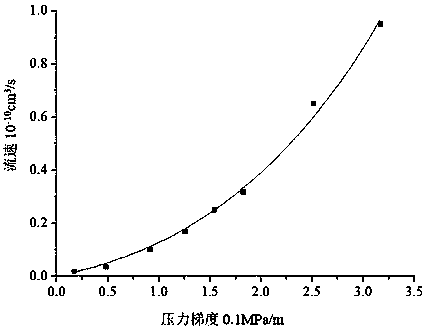

[0033] In step 4, use the multifunctional core displacement device to measure the steady-state pressure gradient-flow relationship, and draw the relationship curve between the displacement pressure gradient and the flow rate.

[0034] In step 5, the conventional core parameters and fluid parameters obtained in steps 1-3 are brought into the following formula, and the formula is applied to fit the displacement pressure gradient-flow rate relationship curve in step 4. The fitting formula used is

[0035] Q=0.0...

Embodiment 2

[0039] In step 1, the conventional basic parameters of the core used in the experiment: the core length is 69mm, the diameter is 25mm, the porosity is 0.15, and the permeability is 2mD.

[0040] In step 2, the simulated oil parameters for the experiment: the simulated viscosity is 2mPa / s, and the volume coefficient is 1.1.

[0041] In step 3, the static method is used to measure and simulate the minimum starting pressure gradient through the low permeability core as 0.002MPa / m.

[0042] In step 4, use the multifunctional core displacement device to measure the steady-state pressure gradient-flow relationship, and draw the relationship curve between the displacement pressure gradient and the flow rate.

[0043] In step 5, the conventional core parameters and fluid parameters obtained in steps 1-3 are brought into the following formula, and the formula is applied to fit the displacement pressure gradient-flow rate relationship curve in step 4. The fitting formula used is

[0044] Q=0.000...

Embodiment 3

[0048] In step 1, the conventional basic parameters of the core used in the experiment: the core length is 127mm, the diameter is 25mm, the porosity is 0.11, and the permeability is 8.25mD.

[0049] In step 2, the simulated oil parameters for the experiment: the simulated viscosity is 2mPa / s, and the volume coefficient is 1.1.

[0050] In step 3, the static method is used to measure and simulate the minimum starting pressure gradient through the low permeability core as 0.0016MPa / m.

[0051] In step 4, use the multifunctional core displacement device to measure the steady-state pressure gradient-flow relationship, and draw the relationship curve between the displacement pressure gradient and the flow rate.

[0052] In step 5, the conventional core parameters and fluid parameters obtained in steps 1-3 are brought into the following formula, and the formula is applied to fit the displacement pressure gradient-flow rate relationship curve in step 4. The fitting formula used is

[0053] Q=...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com