Fiber grating sensor for microearthquakes and manufacturing method of such fiber grating sensor

A technology of microseismic sensor and fiber grating, which is used in instruments, measuring devices, measuring ultrasonic/sonic/infrasonic waves, etc., to achieve the effect of easy installation and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be described in detail below in conjunction with the drawings:

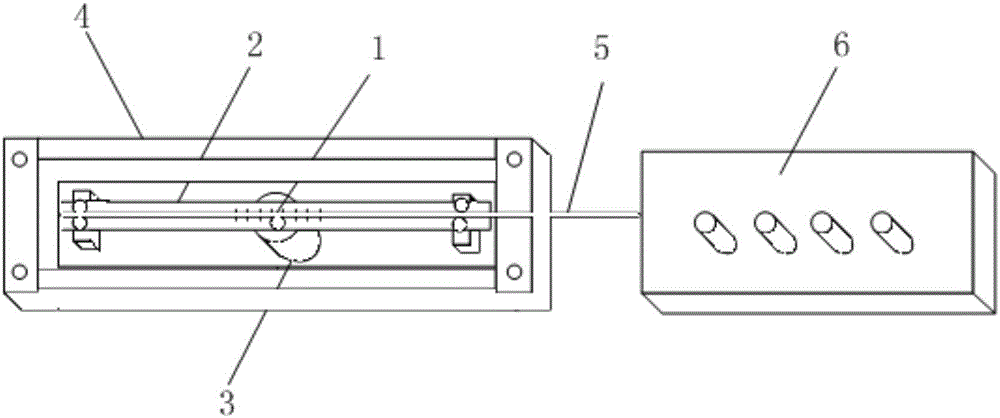

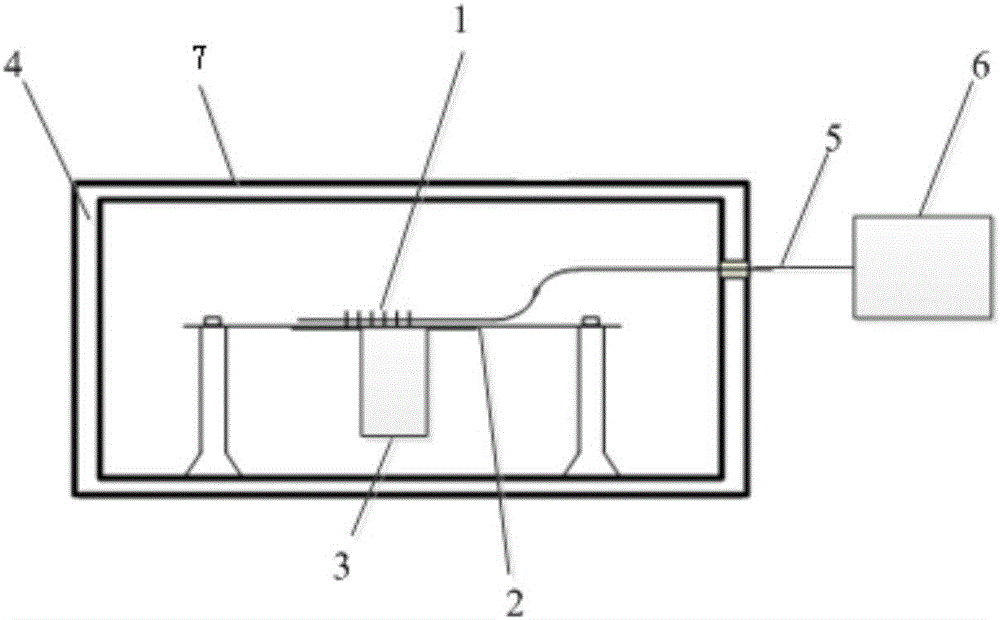

[0038] Such as figure 1 As shown, a new type of fiber grating micro-seismic sensor of the present invention mainly includes fiber grating 1, vibration beam 2, mass 3, housing 4, transmission fiber 5 and signal demodulator 6. The vibration beam 2 is a carbon fiber sheet structure. 2 Screw holes are drilled in the middle and both ends. The center of the mass 3 has a screw hole that can be screwed to the middle of the axial centerline of the vibration beam 2. The shell 1 has a hollow groove structure and screw holes are drilled on both sides. Both ends of the vibrating beam 2 are fixed on the shell 1 with screws, and the mass 3 is fixed directly below the middle of the vibrating beam 2 with screws. The mass 3 cannot be in contact with the bottom surface of the shell 4, and the surface of the axial center line of the vibrating beam 2 is engraved. There are grooves, the two ends of the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com