A measurement method for azimuth angle inspection of microwave guidance equipment

A technology for guiding equipment and measuring methods, applied in theodolite and other directions, can solve problems such as inability to ensure complete coincidence, large operation influence, and errors, and achieve the effects of simple and fast measuring methods, reducing errors, and shortening test time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with the accompanying drawings and embodiments, and the present invention includes but not limited to the following embodiments.

[0026] The present invention comprises the following steps:

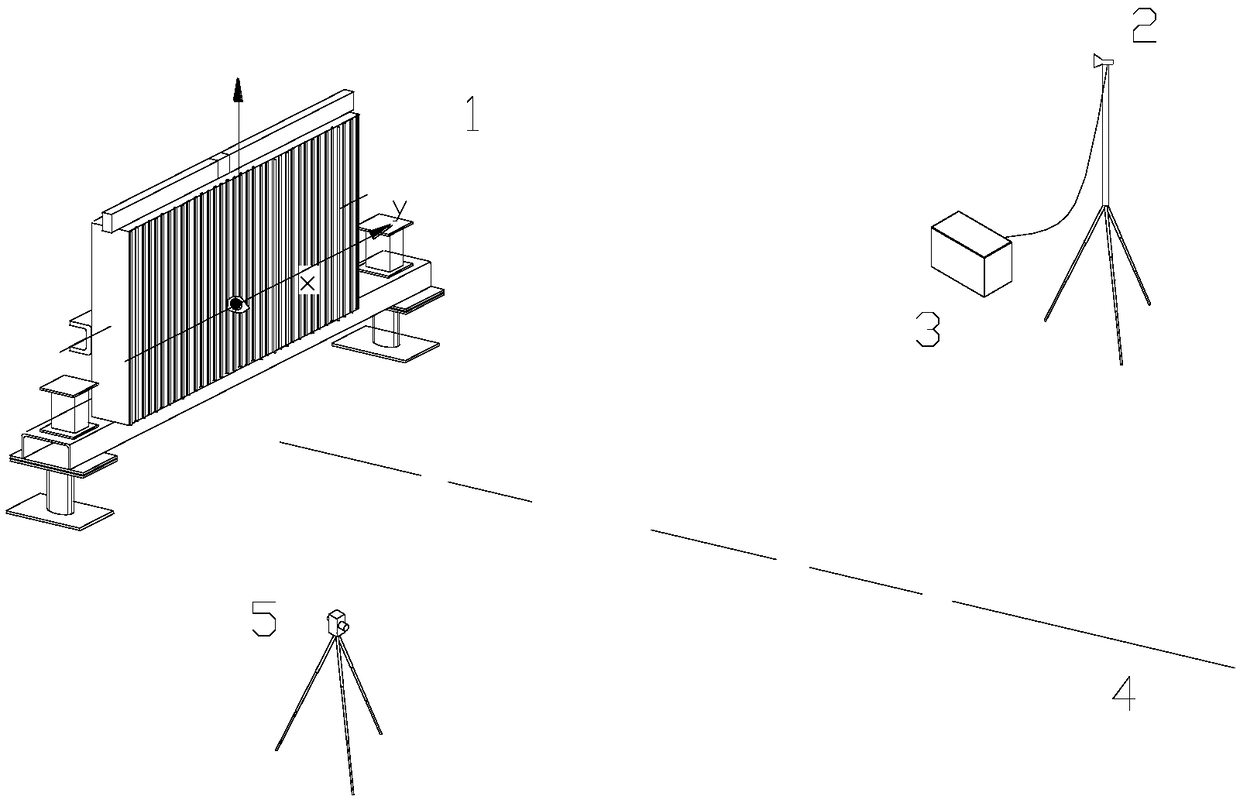

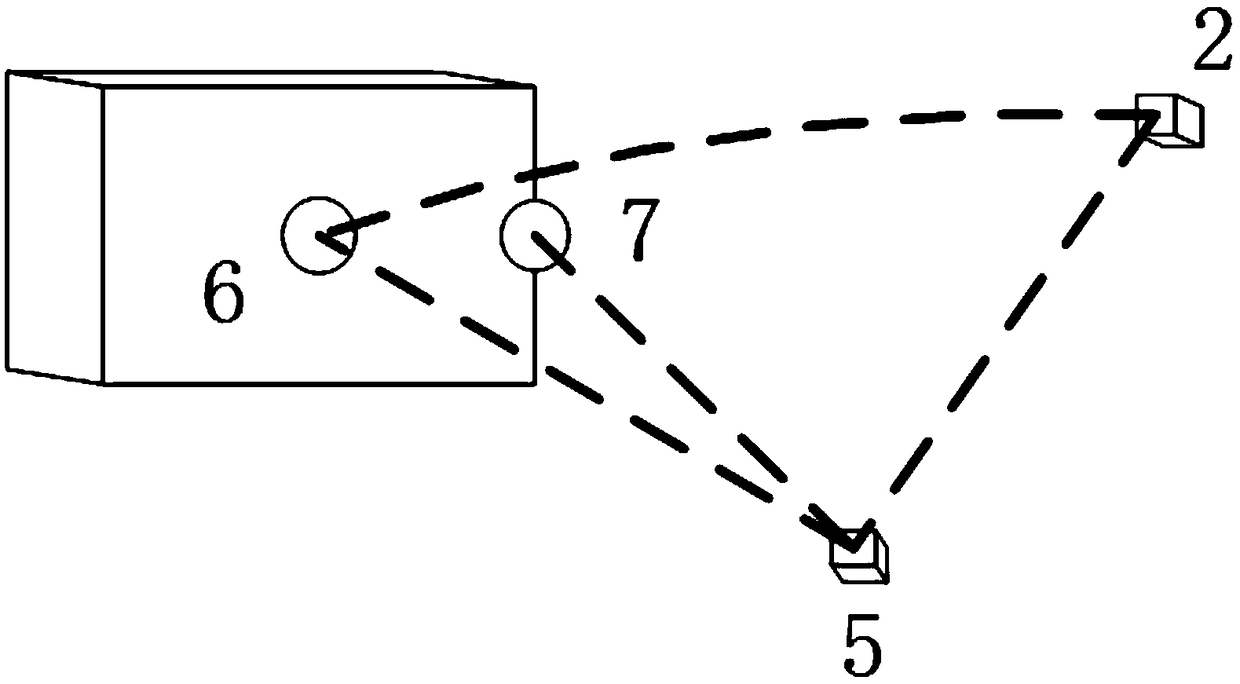

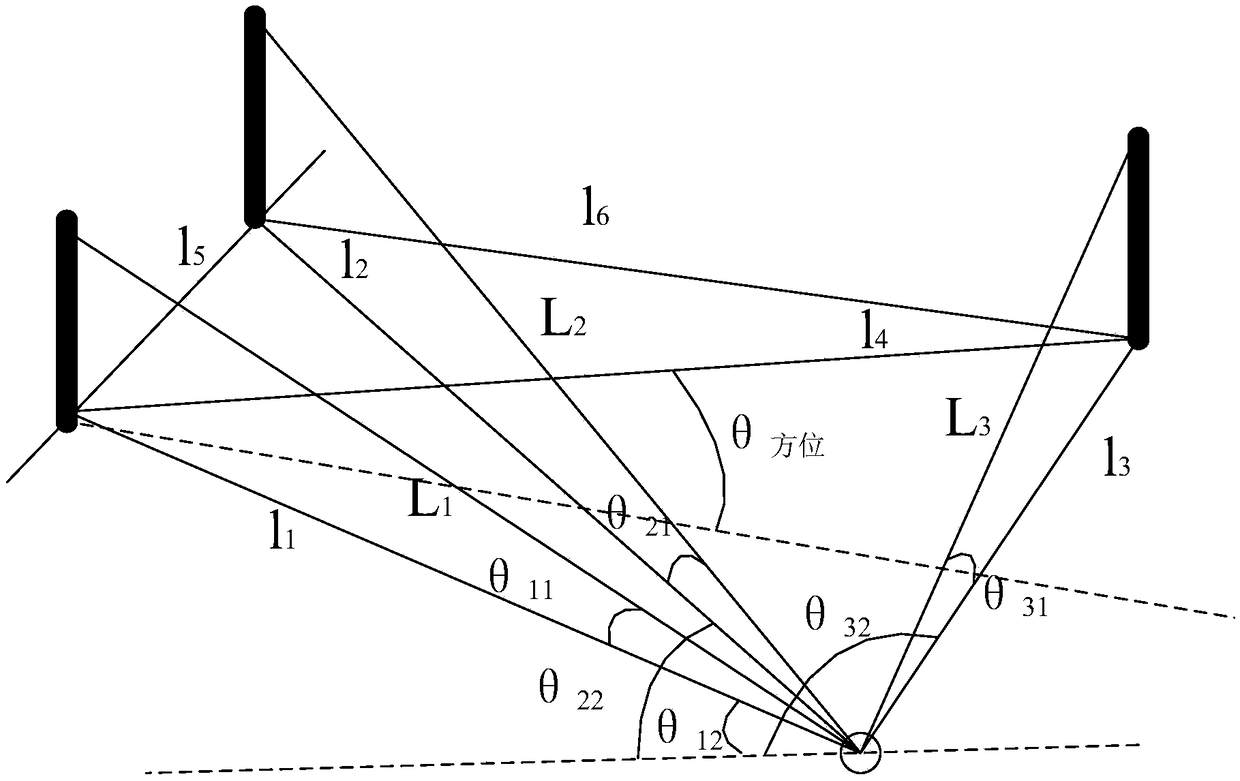

[0027] (1) Arbitrarily select a location within the coverage of the microwave guidance equipment (±40°) to place the dedicated ground angle measurement equipment and the angle measurement test antenna (the two are erected centrally). Then select any position where the antenna of the microwave guidance equipment and the antenna of the angle measurement test can be seen visually to erect the theodolite. Use the theodolite to obtain the following positions: Azimuth Antenna Center (L 1 ,θ 11 ,θ 12 ), any auxiliary point on the azimuth antenna plane (L 2 ,θ 21 ,θ 22 ), the center of the goniometric test antenna (L 3 ,θ 31 ,θ 32 ).

[0028] where L1 is the slant distance from the center point of the azimuth a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com