Measuring rod calibration device and calibration method for calibrating outside micrometer

A calibration device and micrometer technology, which is applied in the calibration of measuring rods for calibration of outer diameter micrometers and the field of calibration devices for calibration rods for calibration of outer diameter micrometers. Reduced universality and other issues, to achieve the effect of good value traceability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

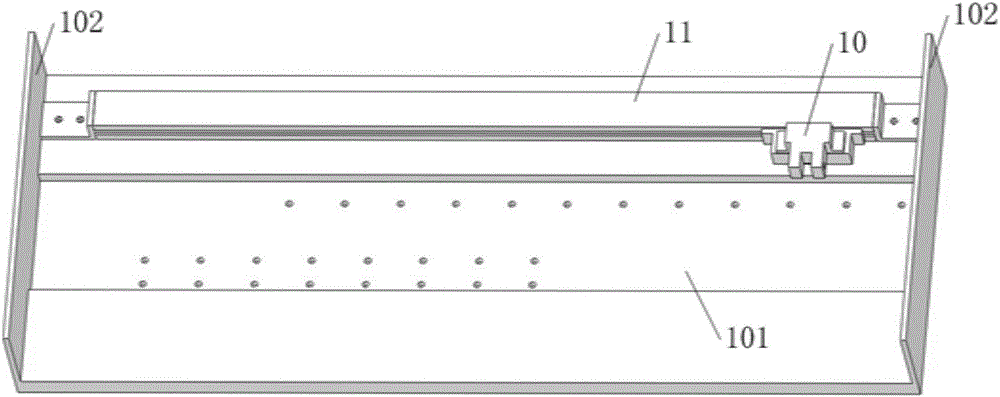

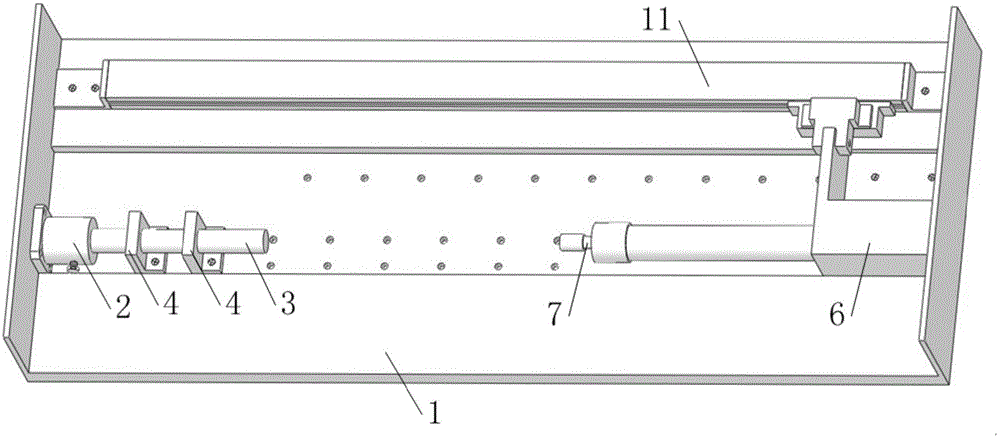

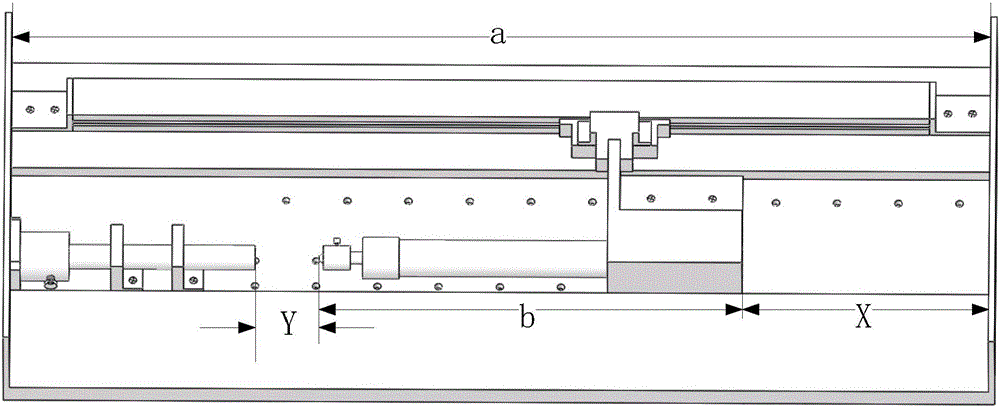

[0049] Such as figure 1 and 2 As shown, a measuring rod calibration device for external micrometer calibration, including an experimental console 1, a grating ruler 11, a slider 6, a power module, a push rod 7, a guide shaft support 2, an electric cylinder motor, and a plurality of L-shaped shafts Support 4, and eccentric spherical measuring cap 13, centering spherical measuring cap 14, plane measuring cap 15.

[0050] Described experimental console 1 comprises chute 101 and two baffle plates 102 vertically fixed on chute 101 two ends; Grating scale 11 is installed between two baffle plates 102, and is parallel with described chute 101; Slide block 6 Installed in the chute 101, can move along the direction of the chute, and connected with the reading head 10 of the grating ruler 11; the electric cylinder motor is connected with the power module, and both are installed in the slider 6, and one end of the push rod 7 is connected with the electric cylinder motor The output shaf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com