A blast hole charging and plugging device

A blasthole charge and blasthole technology, which is applied in blasting and other directions, can solve the problems that air spacers cannot be used, the blasting effect is not ideal, and it is difficult to couple the charge, so as to reduce the cost of explosive consumption and reduce the workload of workers , the effect of reducing the output rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

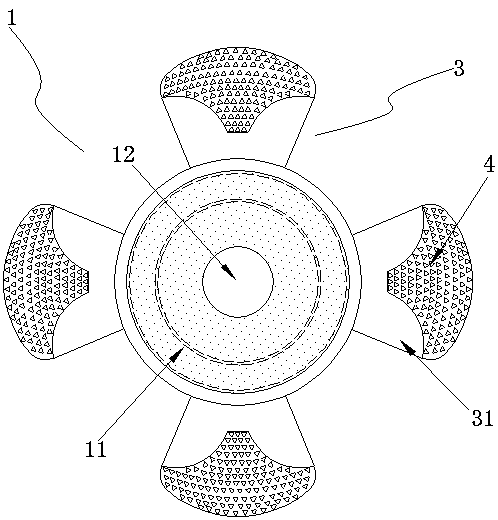

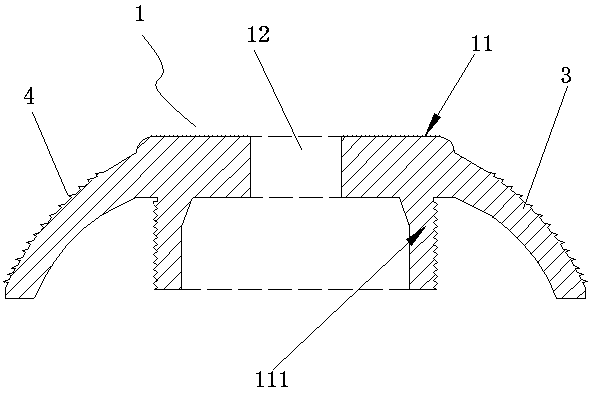

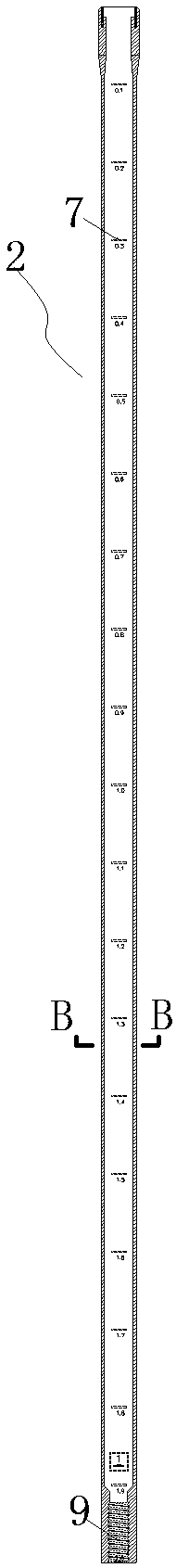

[0034] like Figure 1~6 As shown, a gun hole charging and blocking device includes a disc 1 and a head rod 2 detachably connected with the disc 1 . The disc 1 includes a tray 11 , an elastic and tough fin 3 arranged around the outer wall of the tray 11 , and a central through hole 12 arranged in the center of the tray 11 . The diameter of the tray 11 is 1 / 2-2 / 3 of the diameter of the blast hole 5 . The diameter of the central through hole 12 is less than half of the diameter of the tray 11 .

[0035] The outer edges of the fins 3 are arc-shaped and can be attached to the wall of the blasthole, and the outer diameter of the fins 3 is slightly larger than the diameter of the blasthole 5 . The fins 3 include a plurality of 4 to 8 single-wings 31 arranged at intervals, and the single-wings 31 are fan-shaped. The longitudinal section of the single wing 31 is arc-shaped, and the joint between the single wing 31 and the outer wall of the tray 11 is higher than the outer edge of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com