Municipal sewer pipe repair device and its construction method

A pipeline repair and municipal technology, applied in the direction of pipe components, special pipes, pipes/pipe joints/pipe fittings, etc., can solve the problems of formation pollution, sewage seepage, low efficiency, etc., and achieve the effect of reducing use failure and high durability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

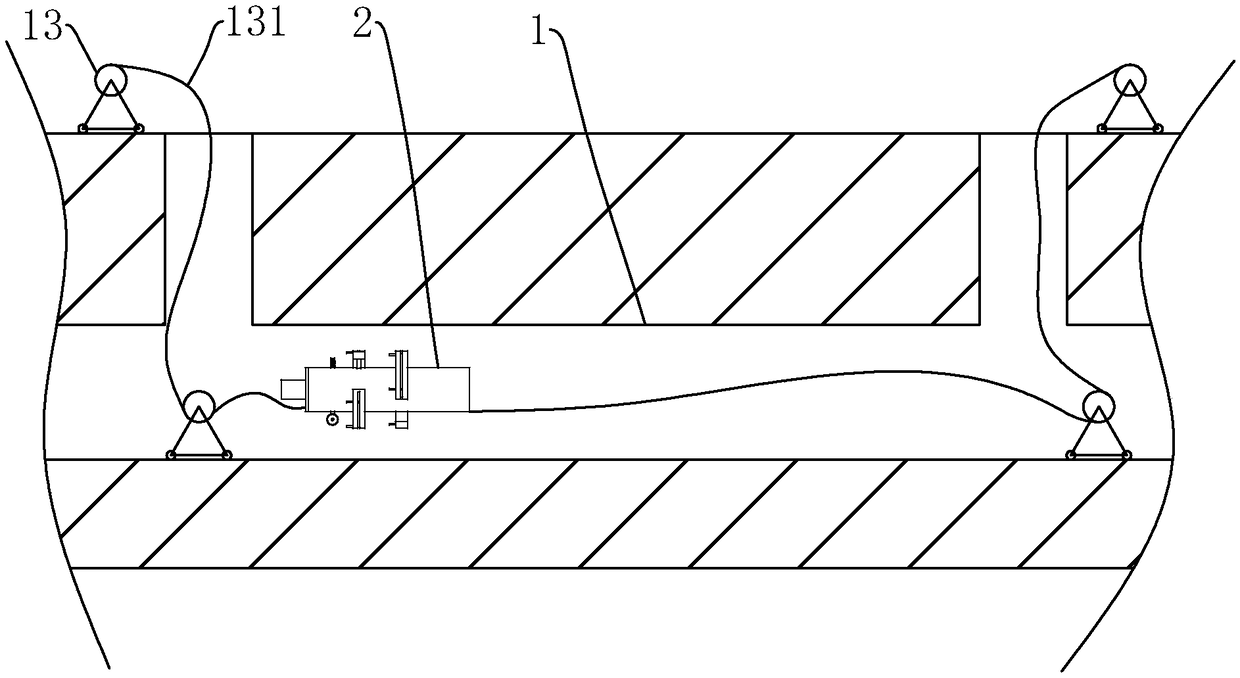

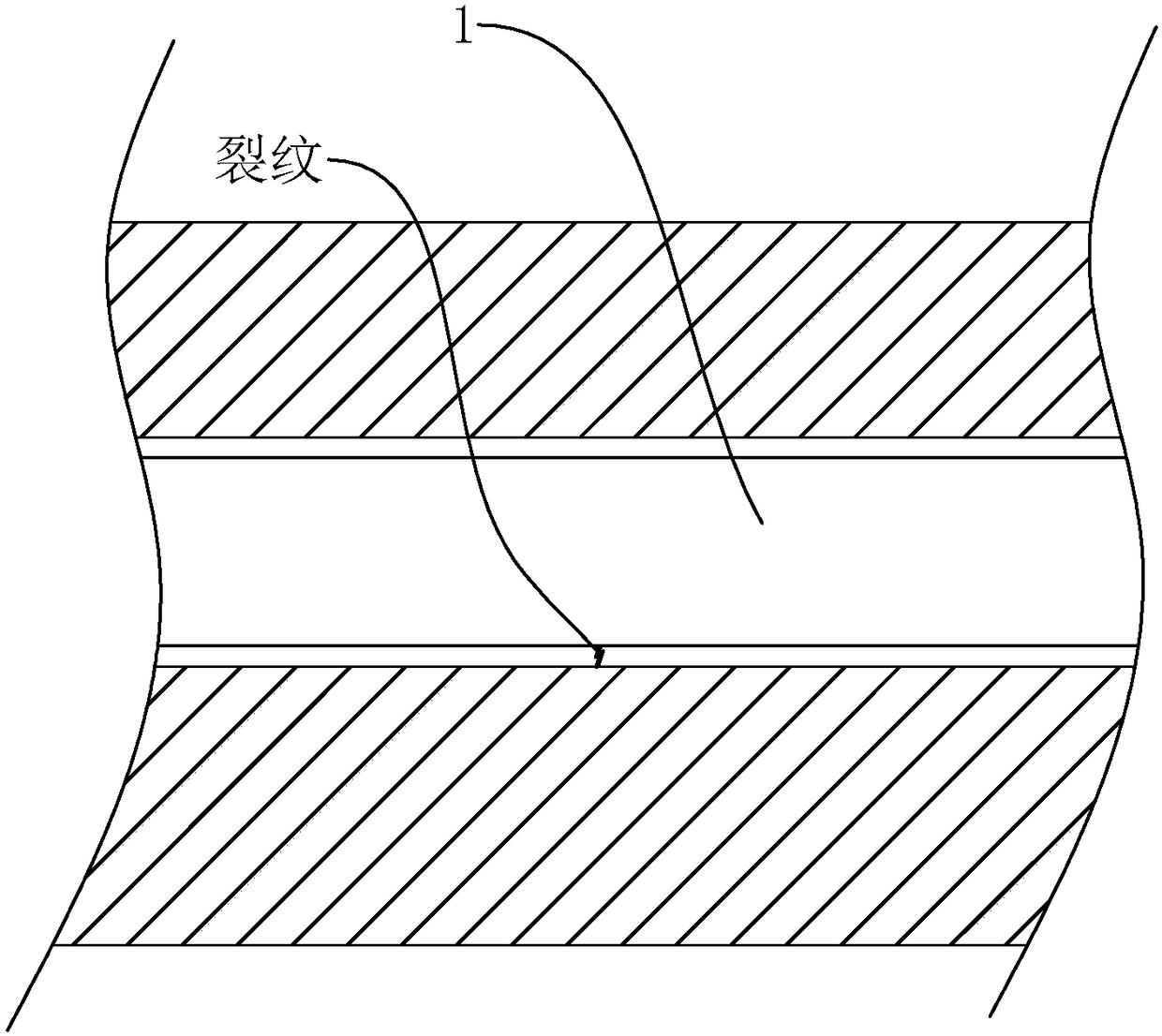

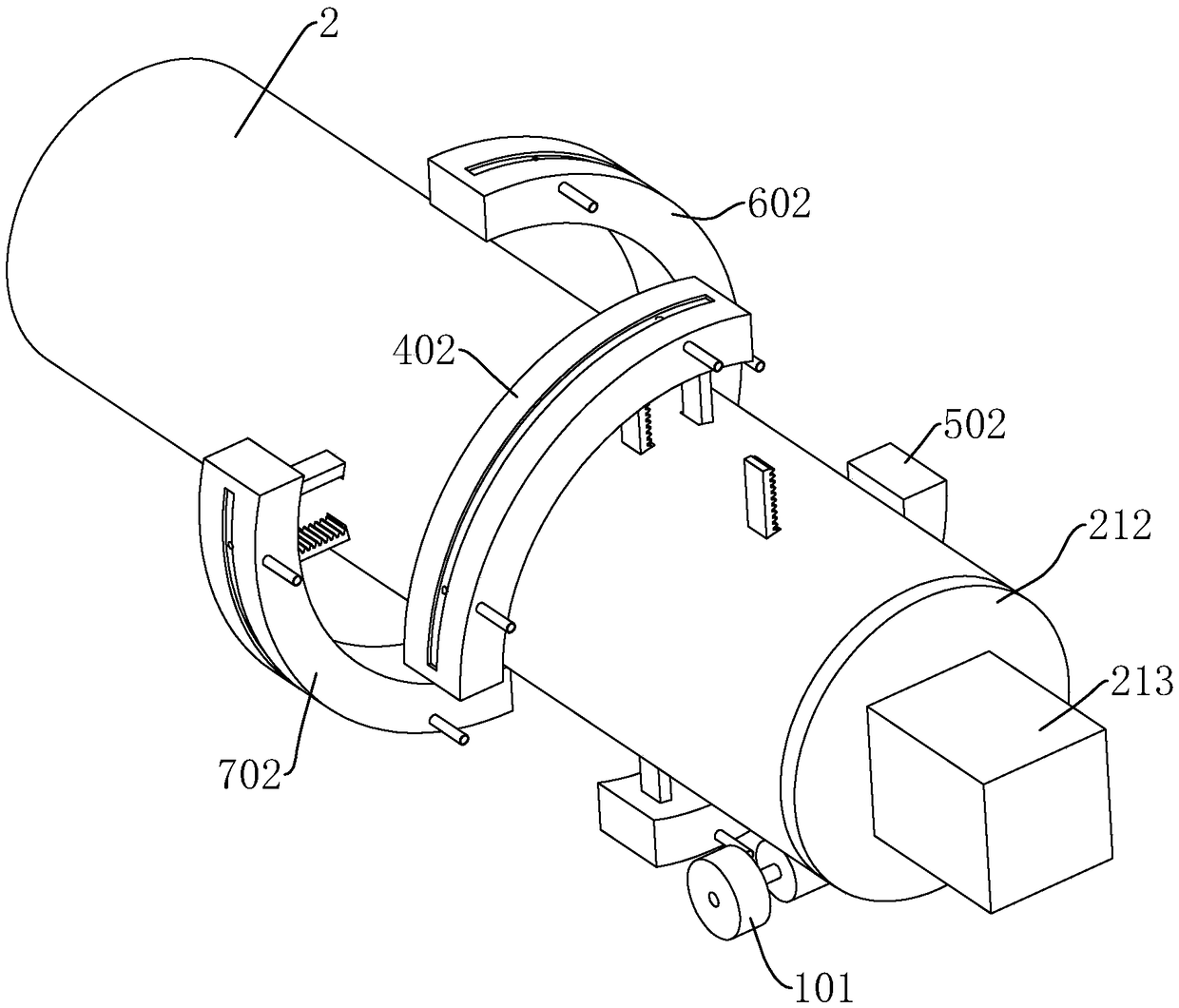

[0052] Example 1: Please refer to image 3 , Figure 4 and Figure 5 , a municipal sewer pipe repair device, mainly used for sewer pipe 1 ( figure 2 shown) repair of cracks. A casing 2 is included, and a synchronous shaft 3 is arranged inside the casing 2 . The synchronous shaft 3 is provided with a first synchronous gear 301, a second synchronous gear 302 and a third synchronous gear 307. When the synchronous shaft 3 rotates, the first synchronous gear 301, the second synchronous gear 302 and the third synchronous gear 307 will be simultaneously rotated. .

[0053] combine Figure 7 and Figure 8a and Figure 8b , the first synchronous gear 301 is provided with a first adjusting rod 4 and a second adjusting rod 5 on both sides of the Y-axis direction, and the first adjusting rod 4 and the second adjusting rod 5 pass through the first rack 401 and the second gear respectively. The bar 501 meshes with the first synchronous gear 301, and the second synchronous gear 302 i...

Embodiment 2

[0059] Embodiment two: a kind of construction method of municipal sewer pipeline repair, comprises the following steps:

[0060] Step 1: Excavate vertical passages on both sides of the pipeline to be repaired 1 for placing repair devices;

[0061] Step 2: Prepare the first brush plate 402, the second brush plate 502, the third brush plate 602, and the fourth brush plate 702 that match the pipeline 1 to be repaired, and connect them to the first adjustment rod 4 and the second brush plate respectively. Adjusting lever 5, the third adjusting lever 6, the fourth adjusting lever 7;

[0062] Step 3: Connect the traction line 131 to both ends of the casing 2, connect the steam pipe 802 to the heating furnace, and connect the grease injection pipe 801 to the grease injection device;

[0063] Step 4: Put in the repair device, start the first drive motor 9 so that the first brush plate 402, the second brush plate 502, the third brush plate 602, and the fourth brush plate 702 conflict ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com