Floating nut mechanism

A technology of floating nuts and drive nuts, which is applied in the direction of mechanical equipment, transmission devices, belts/chains/gears, etc., which can solve problems such as excessive noise transmission, bending deformation of guide rails, and processing errors, and achieve the elimination of misalignment errors, assembly and adjustment Convenience, effect of prolonging exercise life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

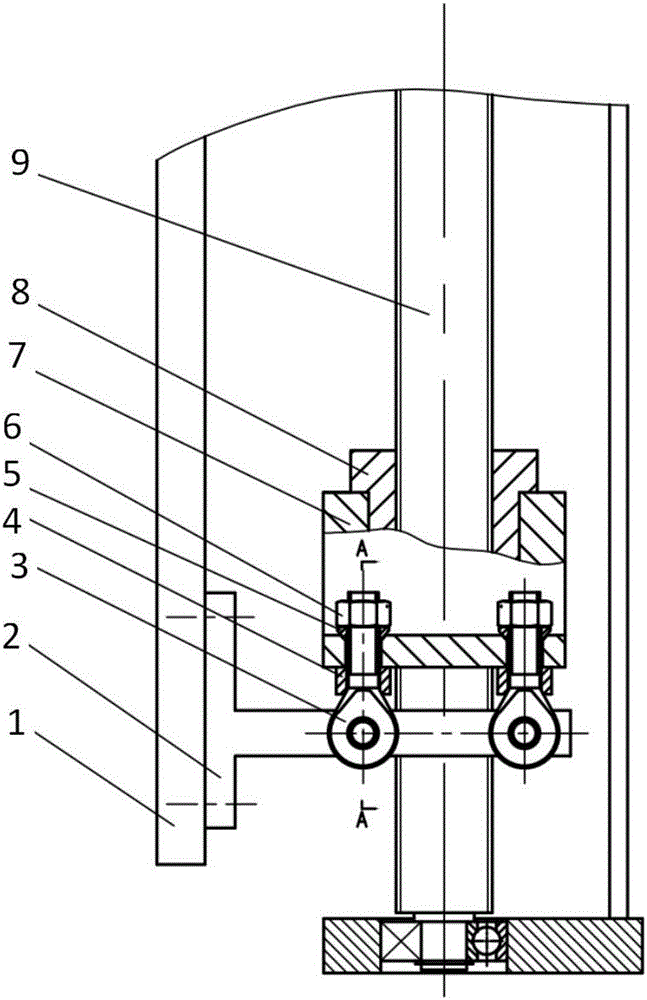

[0024] Floating nut mechanism of the present invention, as Figure 1-2 shown.

[0025] A connection bracket 2 is fixed on the lifting block 1 . The inner holes of four joint bearings 3 are sleeved on pin shaft 12, see A-A sectional view, pin shaft 12 is fixed on the outer surface of connecting bracket 2 by pin 10, forms a four-bar linkage swing mechanism. The externally threaded rod of the joint bearing 3 passes through the through hole of the nut seat 7 and is connected by the hex nut 6, and the upper and lower contact parts of the nut seat 7 are transitioned by the lower spherical washer 4 and the upper spherical washer 5 respectively. The transmission nut 8 is fixed in the nut seat 7 with screws, and the lifting movement of the lifting block 1 is realized by the screw rod 9 screwed in therein.

[0026] The floating nut mechanism of the present invention can realize two-way swing through the four joint bearings 3, and in another external direction, due to the effect of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com