A complex formation pretreatment process

A complex formation and pretreatment technology, applied in wellbore/well components, drilling equipment and methods, and production fluids, etc., can solve the problems of easy slippage of the expansion pipe, unsatisfactory sealing effect, and limited expansion force, etc. To achieve the effect of reducing construction risk and construction difficulty, reducing construction cost and good expansion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

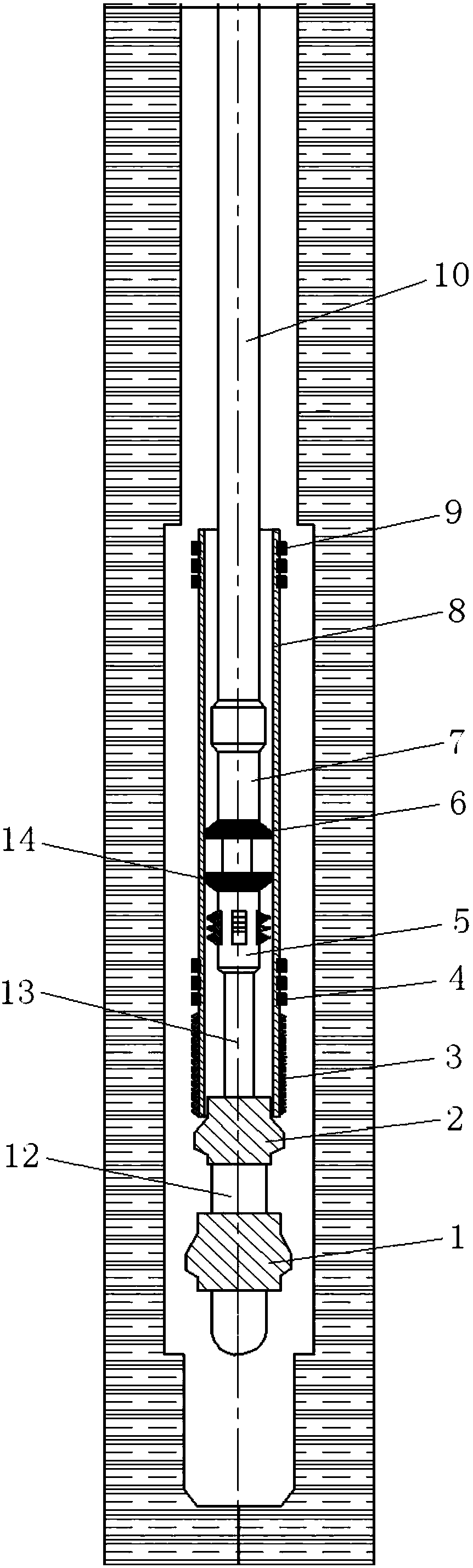

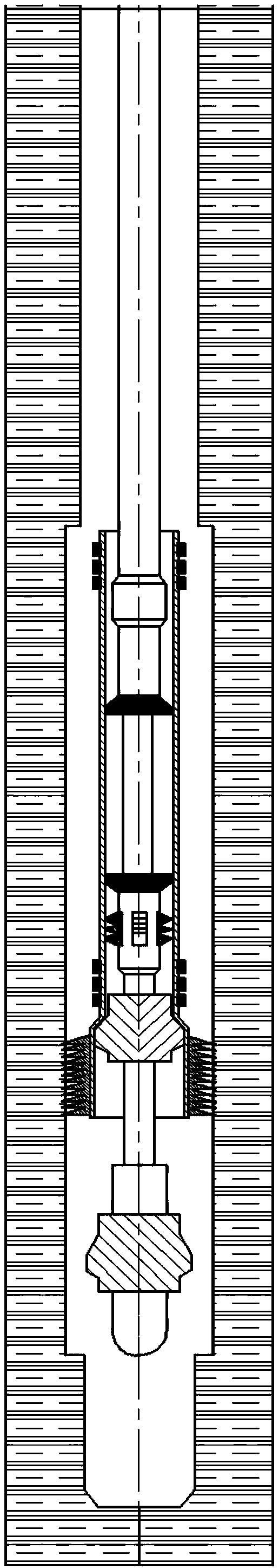

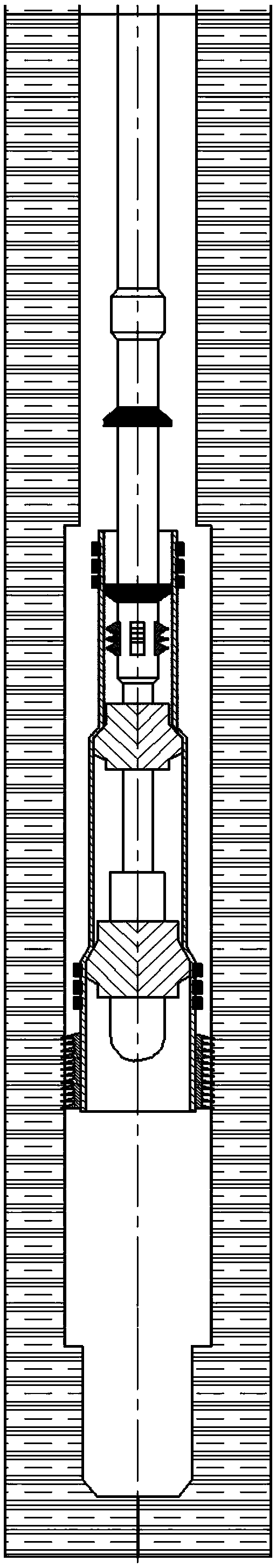

[0020] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 , Figure 7 , Figure 8 As shown, a complex formation pretreatment process, the process steps are as follows:

[0021] 1. After drilling into complex formations, first start the reaming tool while drilling to perform sizing and reaming of complex formations and within the range of 3 to 5 meters above and below;

[0022] 2. The first expansion process: the solid expansion pipe 8 is lowered so that the two ends of the solid expansion pipe 8 are located at a position of 3 to 5 meters above and below the complex formation, and the expansion system is lowered at the position of the complex formation; the expansion system includes the central pipe 7, The upper end of the central pipe 7 is connected with the drilling tool 10, the lower end of the central pipe 7 is connected with the piston tension rod 13, the upper end of the piston tension rod 13 is connected with the upper thrust piston 6, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com