Tower crane construction method of large steel structure air cooling tower

A construction method and air-cooling tower technology, which is applied to building structures, load-hanging components, buildings, etc., can solve problems such as low construction efficiency, wear and tear of crawler equipment, and occupied space, so as to shorten the construction period, ensure installation accuracy, and facilitate construction. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

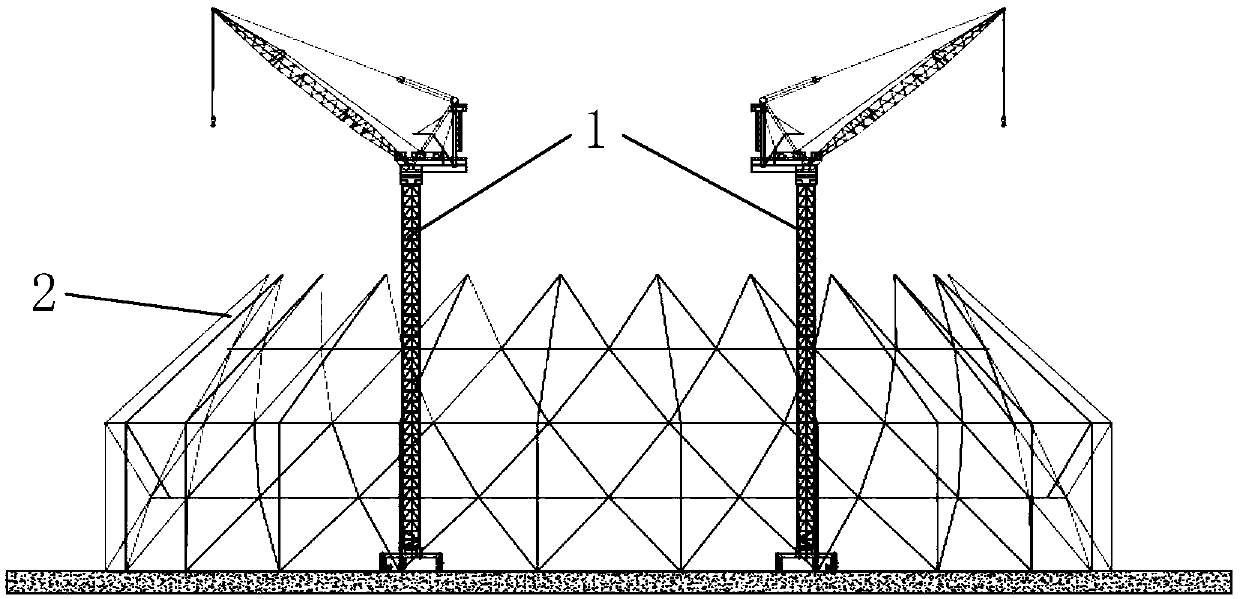

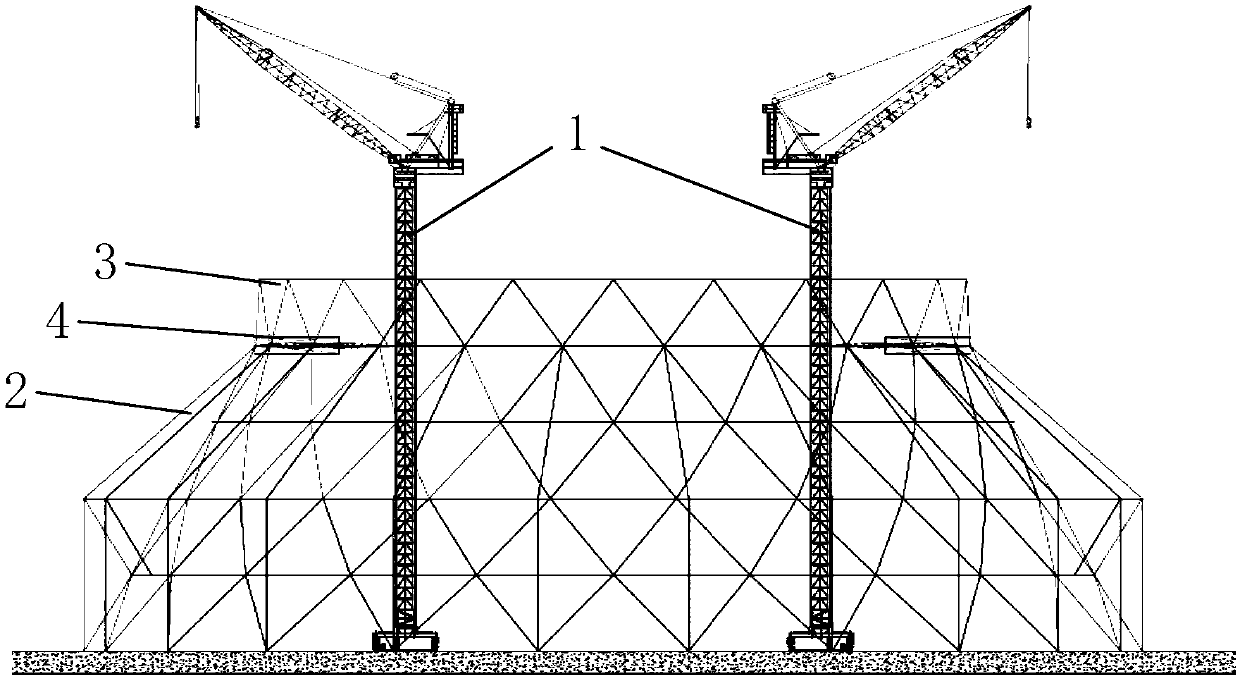

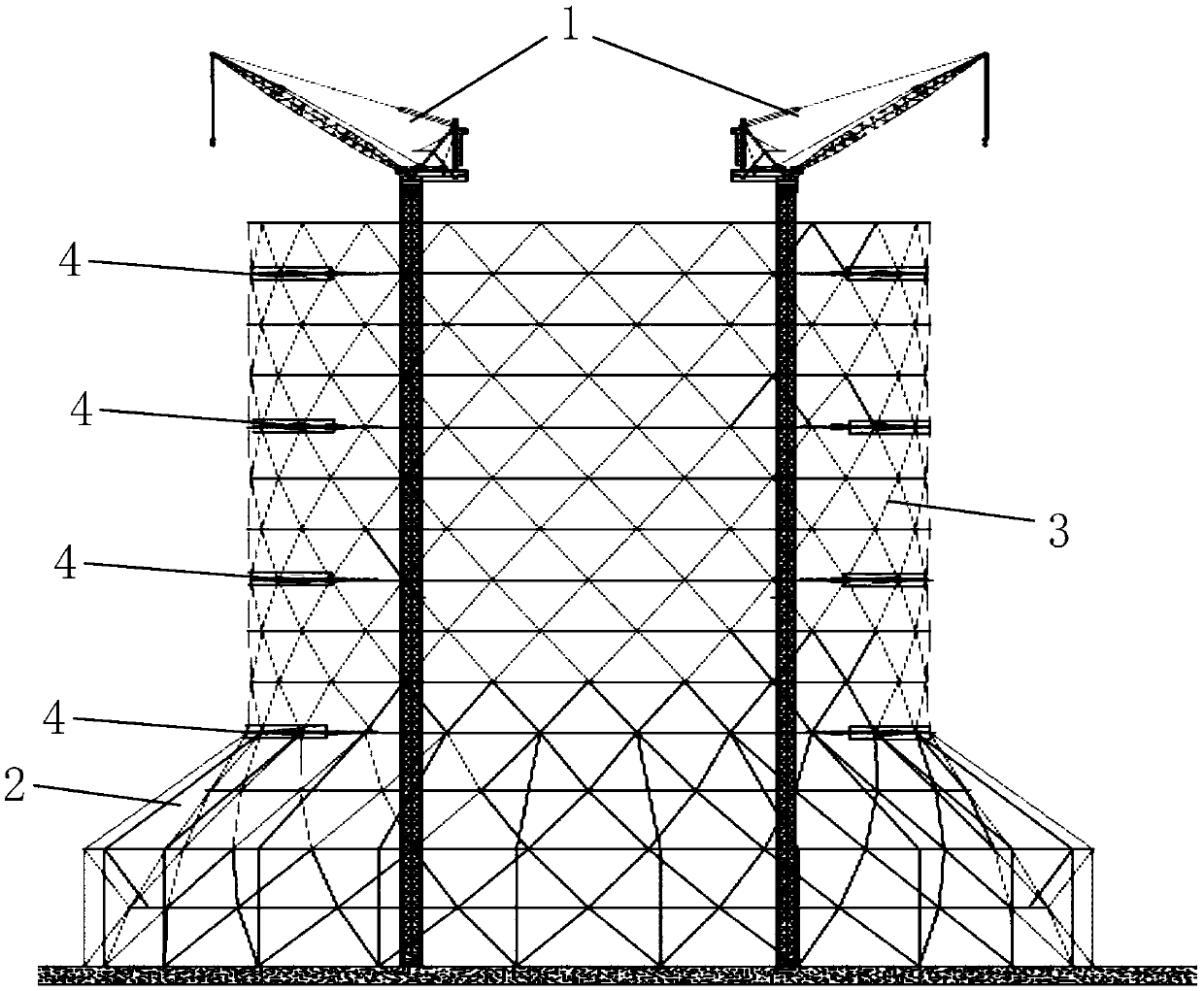

[0028] The following will combine Figure 1 to Figure 6 The tower crane construction method of the large-scale steel structure air-cooling tower provided by the present invention is described in detail, which is an optional embodiment of the present invention. It can be considered that those skilled in the art can modify it within the scope of not changing the spirit and content of the present invention and polish.

[0029] Please refer to Figure 1 to Figure 6 , the invention provides a tower crane construction method of a large-scale steel structure air-cooling tower, comprising the following steps:

[0030] S1: provide two tower cranes 1, the tower cranes 1 are located in the area of the air cooling tower;

[0031] S2: The tower crane 1 realizes linear movement through the rail-type mobile bracket 5, and then carries out the hoisting of the triangular hoisting unit of the conical section 2 through the linear movement and hoisting action of the tower crane 1, and the two...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com