Air cushion pressure regulation device for fluid pulp box and regulation method

A pressure regulation and headbox technology, applied in textile and papermaking, paper machine, wet end of paper machine, etc., can solve the problems of affecting the air cushion pressure, high cost, affecting the spraying speed of the headbox, etc., and achieve low adjustment cost , the effect of high adjustment reliability and precision, and simple device structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

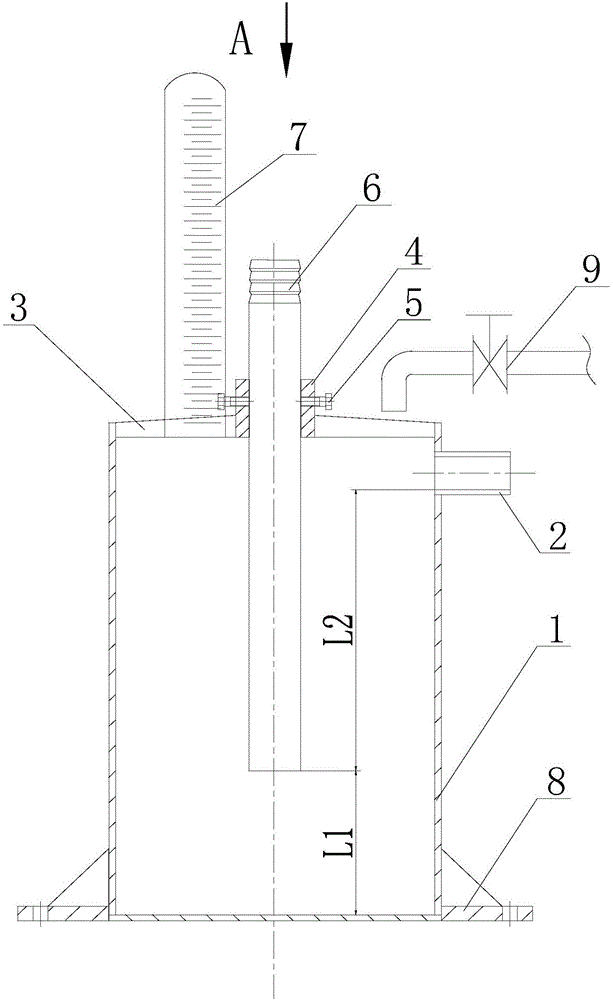

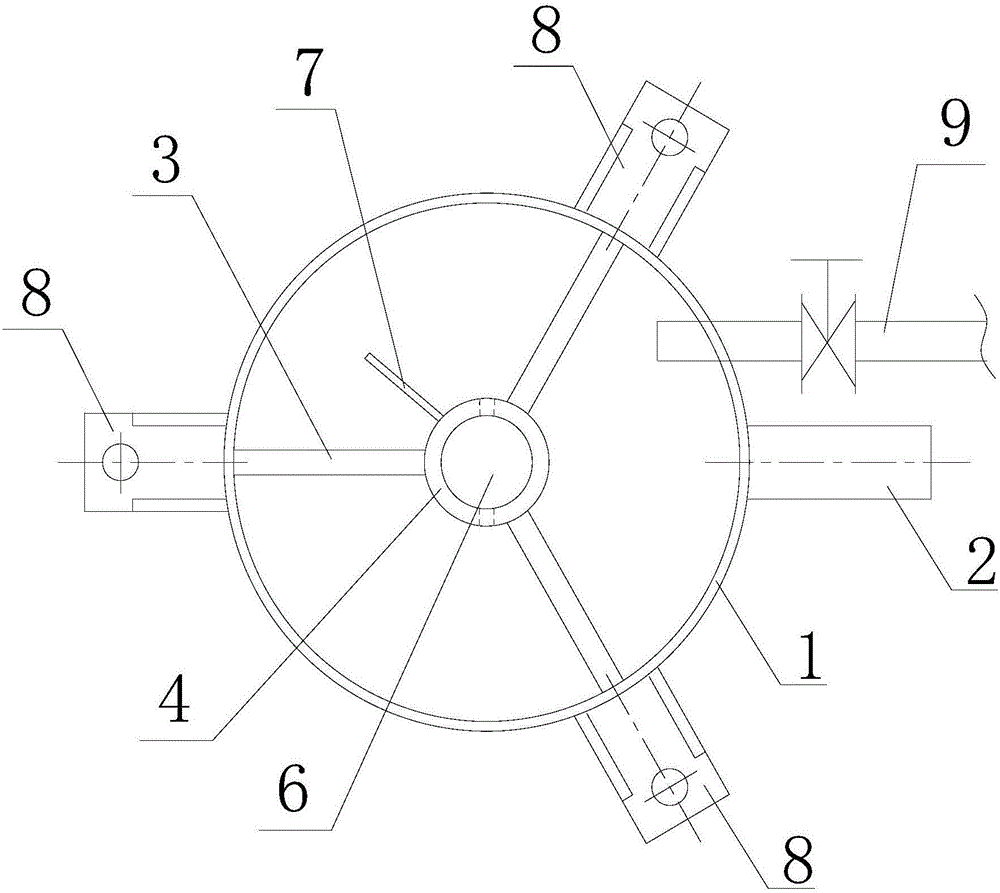

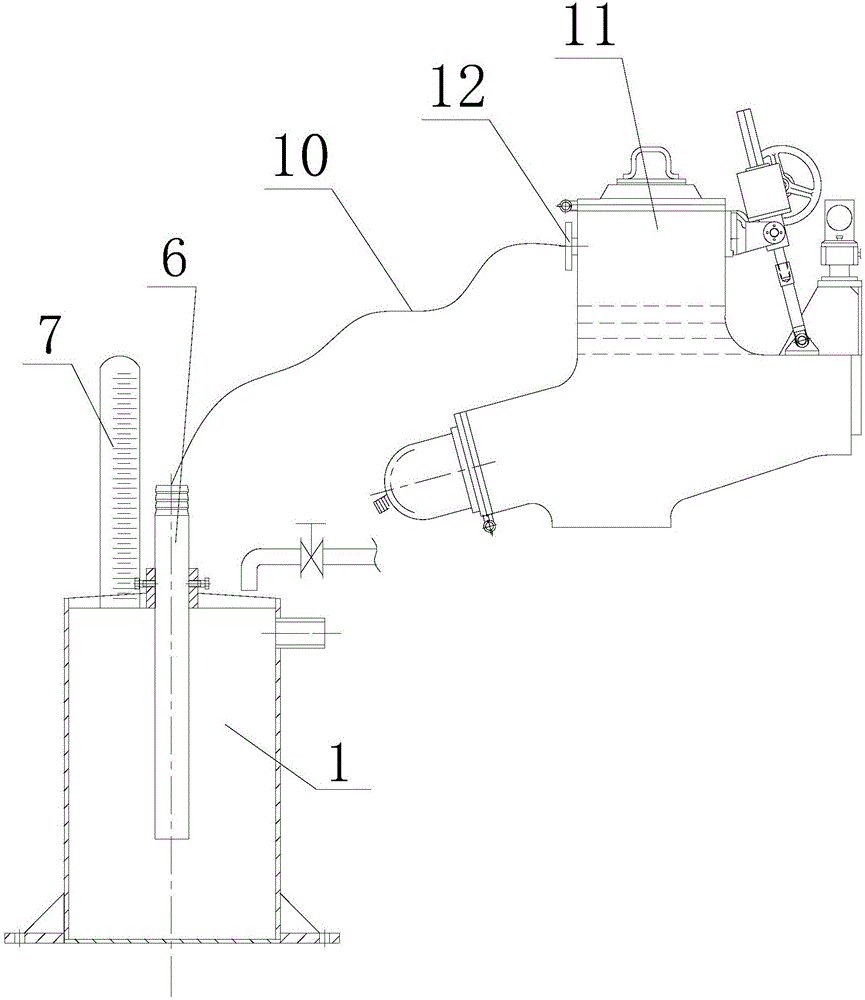

[0046] A kind of air cushion pressure regulating device that present embodiment is used for headbox, such asfigure 1 or figure 2 As shown, it includes pressure regulating barrel 1, pressure regulating pipe 6 and scale 7. The pressure regulating pipe is set in the middle of the pressure regulating barrel and its lower end extends into the pressure regulating barrel. The upper end of the pressure regulating pipe is connected with the air cushion chamber of the headbox, and the scale is fixed. It is arranged on the top surface of the pressure regulating barrel and parallel to the pressure regulating pipe; a supplementary water pipe 9 is arranged above the pressure regulating barrel, and an overflow pipe 2 is arranged on the side wall of the pressure regulating barrel. The air cushion pressure regulating device is installed on the driving side of the paper machine close to the headbox, such as image 3 As shown, the upper end of the pressure regulating pipe is connected with the ...

Embodiment 2

[0058] In this embodiment, the device described in Embodiment 1 can realize a method for adjusting the air cushion pressure of the headbox, which includes the following steps:

[0059] (1) An air cushion is formed in the air cushion chamber of the headbox, and the pressure regulating pipe communicates with the air cushion chamber;

[0060] (2) Pre-adjust the depth of the pressure regulating tube extending into the water in the pressure regulating barrel, so that the depth of the pressure regulating pipe extending into the water is equal to the height of the water column corresponding to the air cushion pressure;

[0061] (3) During the use of the headbox, the headbox forms the air cushion pressure through the intake pipe, and adjusts the air cushion pressure through the pressure regulating pipe exhaust. When the height of the water column corresponding to the air cushion pressure is greater than the depth of the pressure regulating pipe extending into the water , the excess ga...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com