Sewing machine and lubricating structure of curved needle slide bar on sewing machine

A lubricating structure and sewing machine technology, which is applied in the direction of sewing machine components, sewing equipment, lubricating/cooling devices, etc., can solve the problems of insufficient lubrication of slide bars, difficult control of lubricating oil, and affecting lubricating effect, etc., to achieve good lubricating effect, Guaranteed lubricating ability and guaranteed lubricating effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

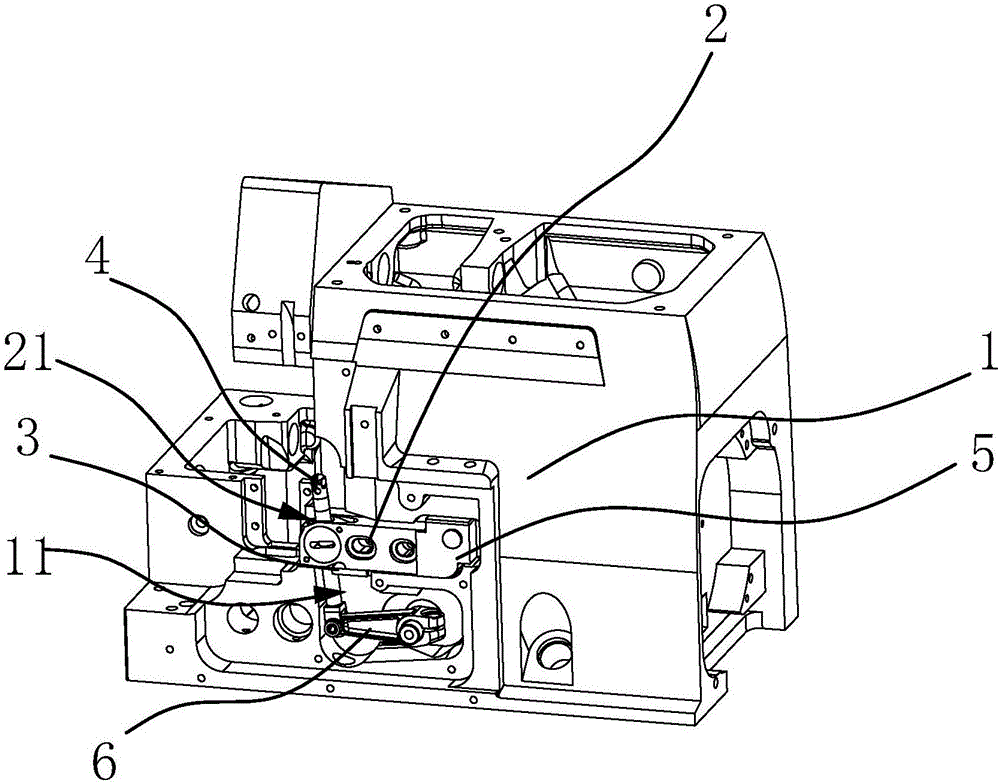

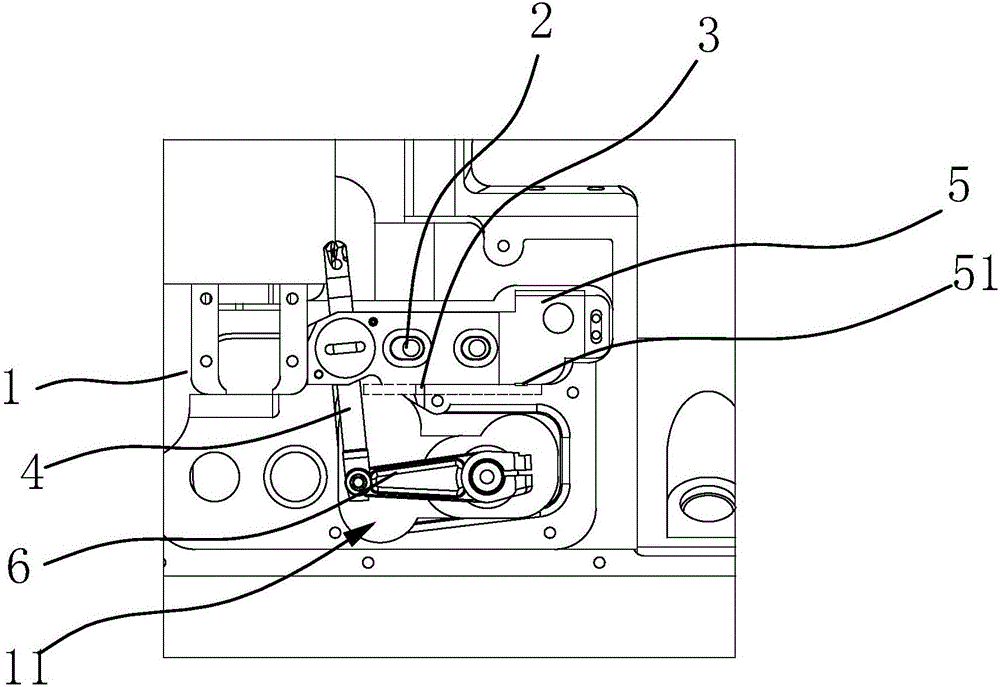

[0025] Such as figure 1 with figure 2 As shown, the sewing machine in this embodiment includes a casing 1, a slide bar 4 and a slide block 2, the slide block 2 is provided with a through hole 21 through which the slide bar 4 slides and is inserted in the through hole 21, and the casing 1 A cavity 11 is provided, the lower end of the slide bar 4 is located in the cavity 11, and a swingable swing arm 6 is provided in the cavity 11; the end of the swing arm 6 is hinged with the lower end of the slide bar 4 and the swing arm 6 can swing Drive the slide bar 4 to reciprocate up and down; the lubricating structure includes an oil storage tank 5 arranged on the casing 1 and an oil-immersed part 3 soaked with grease, the oil storage tank 5 is filled with grease, and the bottom of the oil storage tank 5 is provided with an oil outlet 51 , one end of the oil immersion component 3 is located at the oil outlet 51 of the oil storage tank 5 , and the other end of the oil immersion componen...

Embodiment 2

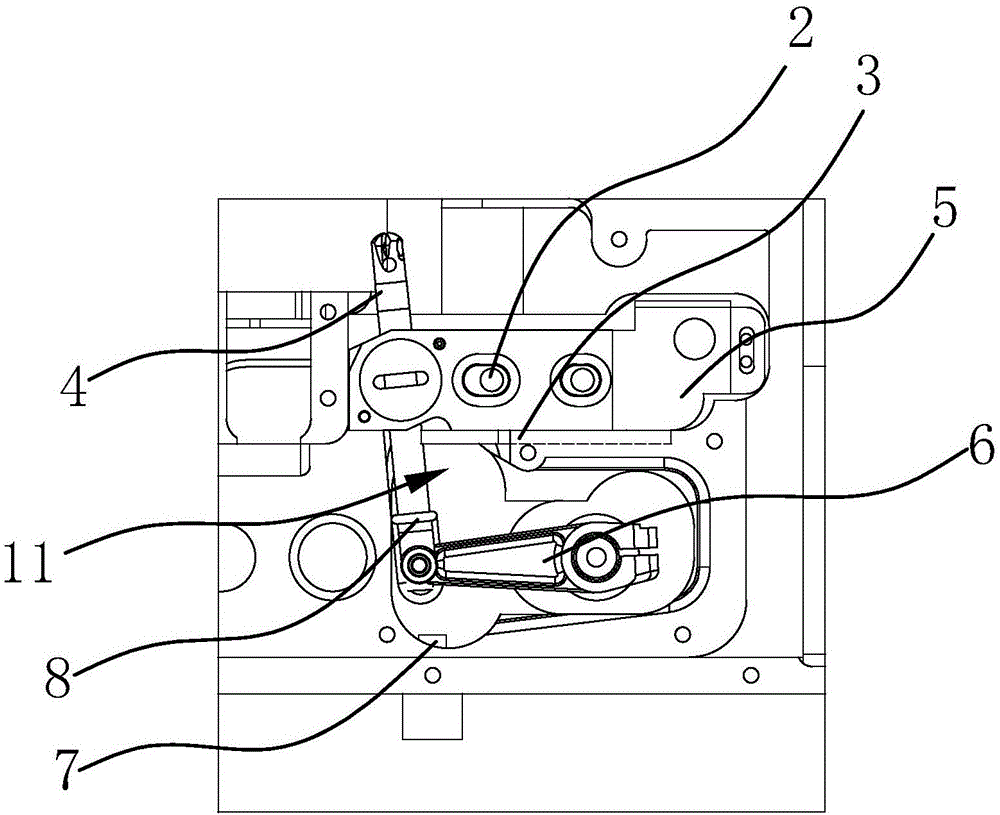

[0028] Such as image 3 As shown, this embodiment is roughly the same as Embodiment 1, the difference is that, as a further improvement, in this embodiment, a linoleum 7 soaked in grease is fixed on the casing 1, and the linoleum 7 is located below the slide bar 4 One end of the linoleum 7 extends into the cavity 11 and faces the lower end of the slide bar 4. When the slide bar 4 moves down, it can be in contact with the linoleum 7. The linoleum 7 lubricates the slide bar 4 from different directions to improve the lubrication. effect; further, the lower end of the slide bar 4 is soaked with grease oil line 8, the oil line 8 is sleeved on the end of the slide bar 4, the oil line 8 moves with the slide bar 4, and the slide bar 4 and the slide block 2 are connected at any time. Lubricate between the joints of the slide bar 4 and the swing arm 6 to ensure the lubrication effect.

Embodiment 3

[0030] This embodiment is substantially the same as Embodiment 1 or Embodiment 2, except that in this embodiment, the end surface of the oil-soaked part 3 facing the slide bar 4 is in contact with the outer peripheral surface of the slide bar 4, so that the grease on the oil-soaked part 3 It can act directly on the slide rod 4 to lubricate it.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com