Air mesh cloth with tapered meshes and manufacturing method thereof

A production method and technology of conical mesh, which is applied in textiles and papermaking, knitting, warp knitting, etc., can solve the problems affecting the quality of sandwich mesh, poor three-dimensional sense and resilience, poor gas exchange effect, etc., and achieve gas conduction Good air permeability, soft hand feeling and good line retention

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The invention will be further explained below in conjunction with the drawings and specific embodiments:

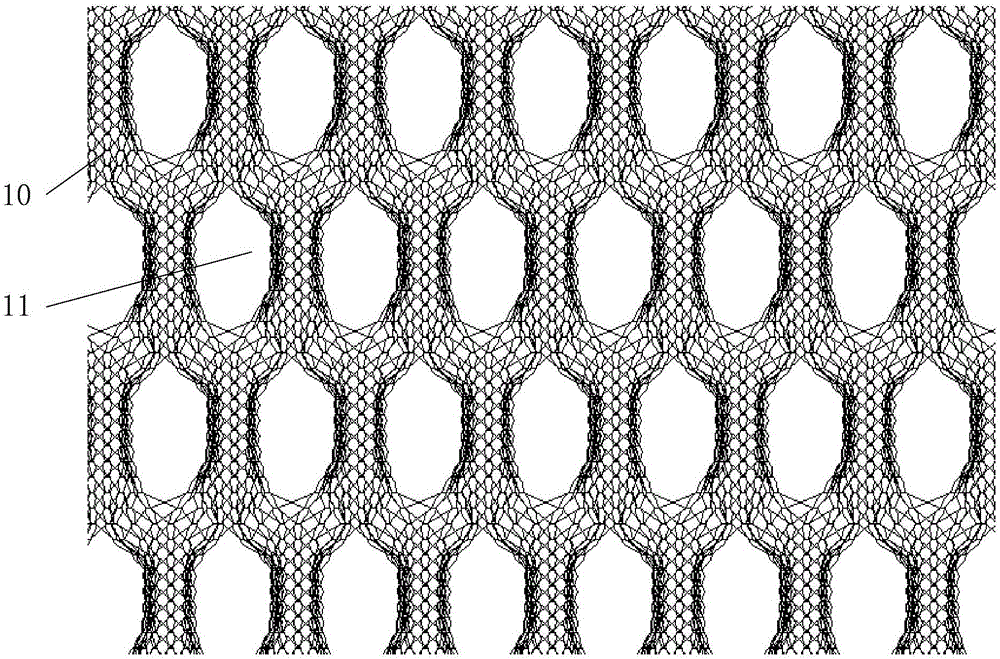

[0035] Such as figure 1 with figure 2 As shown, the sandwich mesh with tapered mesh provided by this embodiment includes a surface layer 10, a bottom layer 20, and a middle layer 30 for connecting the surface layer 10 and the bottom layer 20, wherein the surface layer 10 is evenly distributed with a plurality of second layers. A mesh 11, the bottom layer 30 is evenly distributed with a plurality of second meshes 31 coaxially arranged with the first mesh 11, that is, each first mesh 11 and each second mesh 31 correspond one-to-one. The cross-sectional shape of the first mesh 11 and the second mesh 31 are the same, and the specific shape of the mesh and the specific position and arrangement of the mesh can be designed according to actual needs.

[0036] The cross-sectional area of the first mesh 11 is larger than the cross-sectional area of the second mesh 31, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com