Method for feeding strip provided with seam into furnace and air cushion furnace

A technology of stitching joints and air cushion furnaces, which is applied in the field of heat treatment, can solve the problems of reducing tension or elongation, damage to cleaning rollers and squeezing rollers, and production cannot continue, so as to reduce tension, reduce tension, Avoid the effect of breaking the belt

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

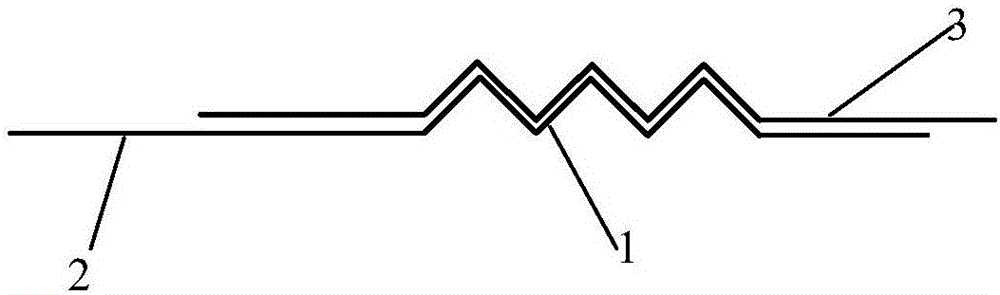

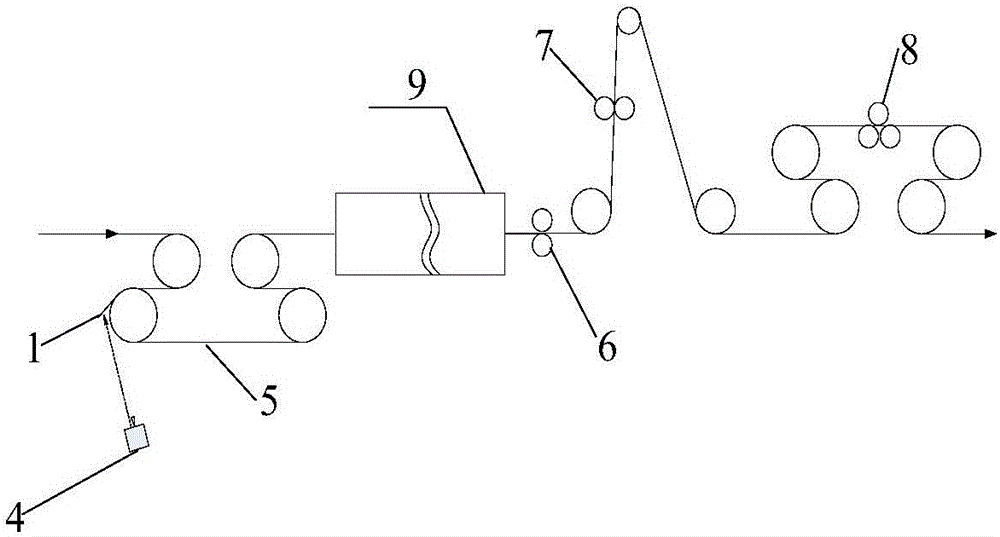

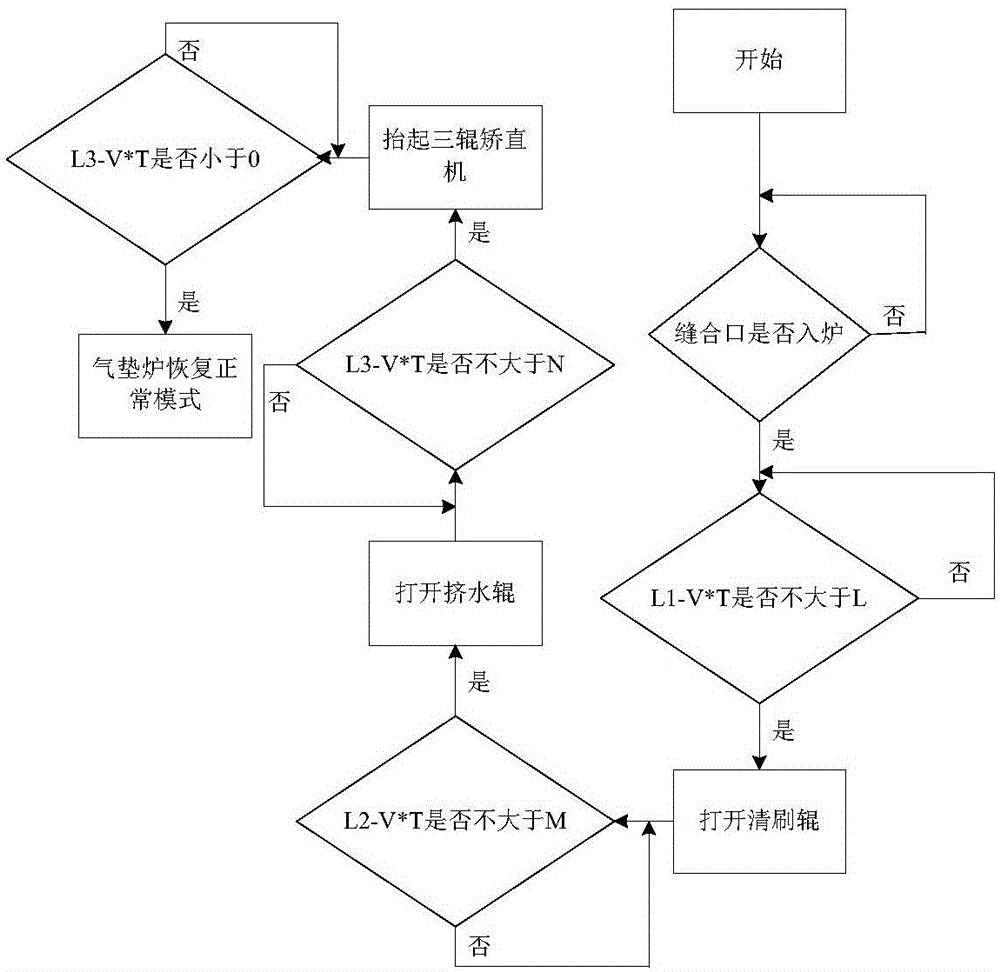

[0023] In view of this, the core of the present invention is to provide a method for strip entering the furnace with stitching openings, which can detect the accurate position of the stitching openings, reduce the tension in the air cushion furnace in time, and reduce the reduction of the three-roll straightener , To reduce its tension and straightening tension, to avoid broken belt; to open the cleaning roller and squeeze roller in time to avoid equipment damage, thereby improving production efficiency.

[0024] Another core of the present invention is to provide an air cushion furnace.

[0025] In order to enable those skilled in the art to better understand the solution of the present invention, the present invention will be further described in detail below with reference to the accompanying drawings and specific embodiments.

[0026] The embodiment of the present invention discloses a method for introducing a strip with a stitching opening into a furnace, which includes detectin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com