Low-water-content oil-proof foaming agent

A technology of low water content and foaming agent, which is applied in the fields of gas field foam drainage agent and oil-resistant low water content foaming agent. To achieve the effect of enhancing the ability of anti-condensate oil, the fluctuation of foam water content is small, and the strength of membrane is enhanced

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

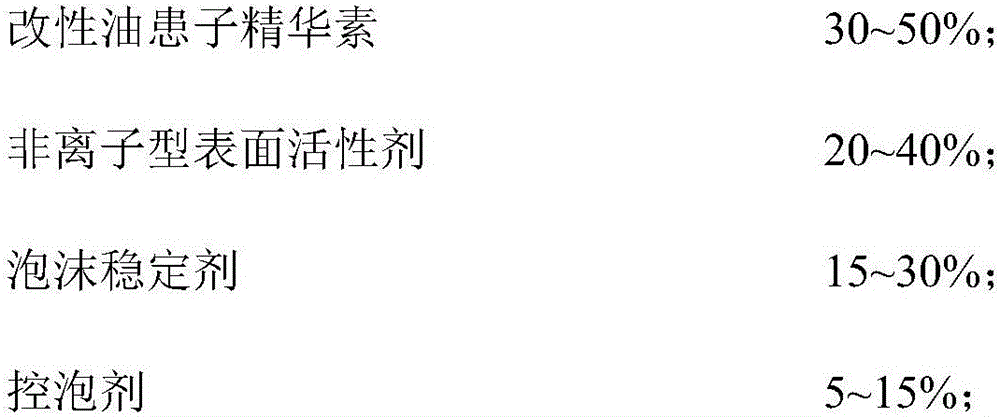

Method used

Image

Examples

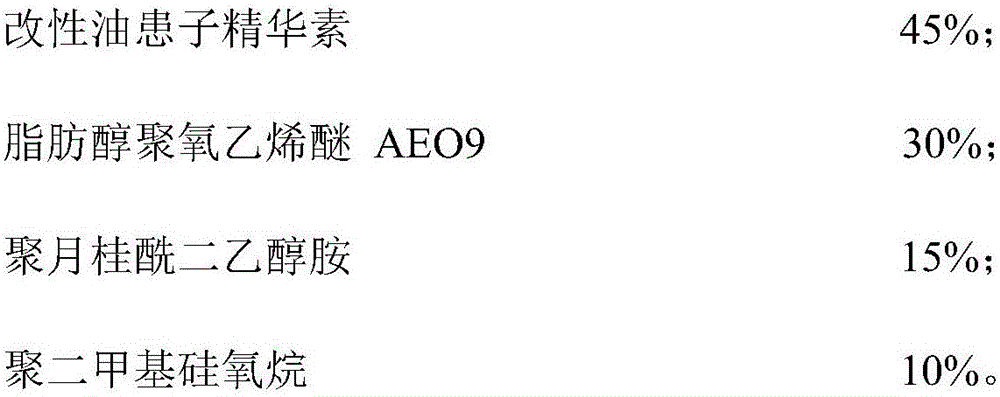

Embodiment 1

[0030] The anti-oil and low water content foaming agent in this implementation is composed of the following components: 30% of modified oil-spotted fruit essence, 40% of fatty alcohol polyoxyethylene ether AEO9, 15% of polylauroyl diethanolamine, polydimethylsiloxane 15% alkanes, that is, the compounding ratio of blowing agent components is 6:8:3:3.

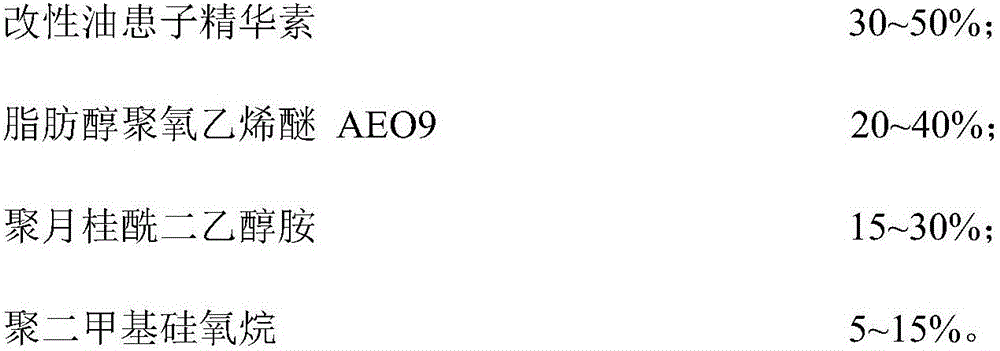

Embodiment 2

[0032] The anti-oil and low water content foaming agent of this embodiment is composed of the following components: 35% of modified oleracea essence, 35% of fatty alcohol polyoxyethylene ether AEO9, polylauroyldiethanolamine 20, polydimethylsiloxane 10% alkanes, that is, the compounding ratio of foaming agent components is 7:7:4:2.

Embodiment 3

[0034] The anti-oil and low water content foaming agent of this embodiment is composed of the following components: 40% of the essence of modified oleracea, 35% of fatty alcohol polyoxyethylene ether AEO9, 30% of polylauroyl diethanolamine, polydimethylsiloxane 10% oxane, that is, the compounding ratio of foaming agent components is 8:7:3:2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com