Special white master batch for liquid packaging film, preparation method and application thereof

A technology of packaging film and white masterbatch, which is applied in the field of plastic packaging materials, can solve problems such as poor sealing, cracking of composite layers, and high cost, and achieve the effects of improving quality stability, good dispersion performance, and comprehensive performance guarantee

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

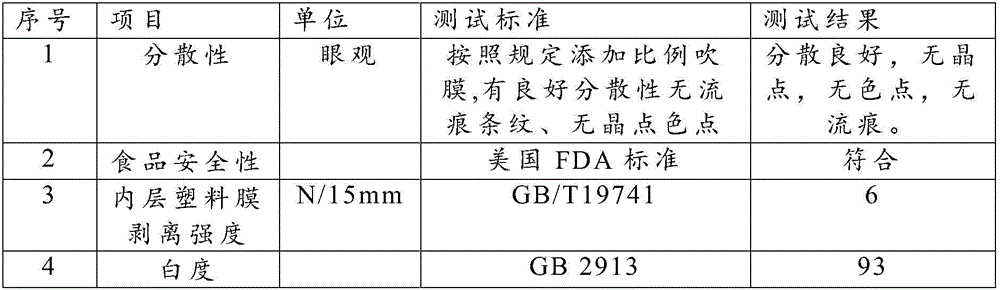

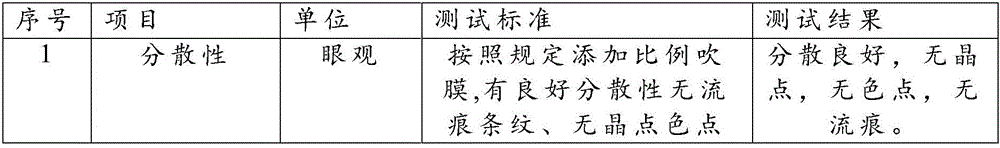

Examples

Example Embodiment

[0030] An embodiment of another aspect of the present invention provides a method for preparing a white masterbatch for liquid packaging films as described in the foregoing embodiment, including the following steps:

[0031] Compounding process: accurately weigh the main ingredients, titanium dioxide, antioxidants, and pigments in parts by weight, and then add the above-mentioned components to the mixer in the order of adding the main ingredients and then other components for mixing. After mixing uniformly, the compounding material is obtained;

[0032] Granulation process: The compounded materials are sent to the preset temperature twin-screw underwater pelletizing and extruding granulator. The compounded materials are melted at high temperature and blended by twin-screw high-speed shearing, extrusion, underwater pelletizing, and dehydration , Obtain the special white masterbatch for liquid packaging film.

[0033] The above embodiments provide a method for preparing a special whit...

Example Embodiment

[0039] Example 1

[0040] Accurately weigh 12 parts of LLDPE, 13 parts of high melting index LDPE, 70 parts of rutile titanium dioxide, 4.5 parts of antioxidants, and 0.5 parts of pigments according to parts by weight, and add LLDPE and high melting index LDPE first, and then add the remaining components Add the above-mentioned components to a high-speed mixer for mixing in the order of fractionation. After the mixing is uniform, the compounded material is obtained.

[0041] The compounding material is fed into the twin-screw underwater pelletizing and extruding granulator. The compounding material sequentially passes through the feeding section 140°C, the melting section 160°C, the plasticizing section 170°C, and the die area after being melted at a high temperature of 190°C. Screw high-speed shearing and blending, extrusion, water cooling, air drying, and pelletizing to obtain white masterbatch 1 for liquid packaging film.

Example Embodiment

[0042] Example 2

[0043] Accurately weigh 14 parts of LLDPE, 13 parts of high melting index LDPE, 68 parts of rutile titanium dioxide, 4.5 parts of antioxidants, and 0.5 parts of pigments in parts by weight, and add LLDPE and high melting index LDPE first, and then add the remaining components Add the above-mentioned components to a high-speed mixer for mixing in the order of fractionation. After the mixing is uniform, the compounded material is obtained.

[0044] The compounding material is fed into the twin-screw underwater pelletizing and extruding granulator. The compounding material passes through the feeding section 145°C, the melting section 165°C, the plasticizing section 175°C, and the die area after being melted at high temperature at 205°C. Screw high-speed shearing and blending, extrusion, water cooling, air drying, and pelletizing to obtain white masterbatch 2 for liquid packaging film.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com