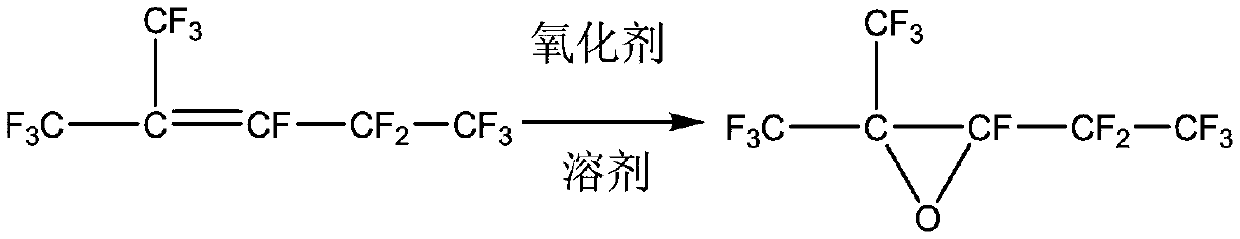

A kind of method for preparing perfluoro-2,3-epoxy-2-methylpentane

A technology of methylpentane and epoxy, which is applied in the field of preparing perfluoro-2,3-epoxy-2-methylpentane, can solve the problems of low formula conversion rate and unstable reaction yield, and achieve the goal of reaction High yield and the effect of reducing the amount of waste liquid generated

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

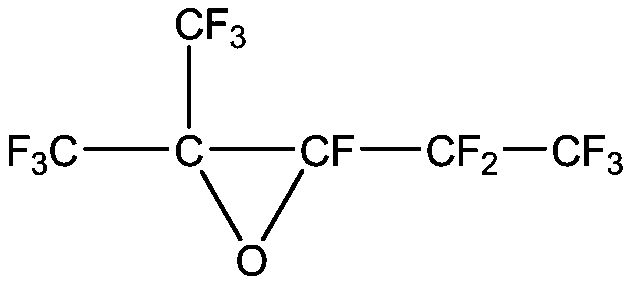

Embodiment 1

[0039] Add 300ml of perfluoro-2-n-propyl-cyclopentyl ether, 2g of potassium permanganate, and add perfluoro-2-methyl-2-pentene (99% )300g, control the reaction temperature at 80°C, the reaction pressure is 0.6MPa, feed oxygen, and react for 6 hours in total. 270.5 g of alkanes, the molar yield is 85.6%.

Embodiment 2

[0041] Add 300ml of perfluoromethylcyclohexane, 3g peroxyphosphotungstate in 1000mL airtight reaction kettle equipped with mechanical stirring, add perfluoro-2-methyl-2-pentene (99%) 300g, Control the reaction temperature at 90°C, the reaction pressure at 0.7MPa, and feed oxygen for a total of 6 hours of reaction. After the reaction, 293.6g of perfluoro-2,3-epoxy-2-methylpentane with a purity of 99% was obtained by separation , the molar yield was 92.9%.

Embodiment 3

[0043] Add 300ml of a 1:1 mixture of perfluoro-2-n-propyl-cyclopentyl ether and perfluoromethylcyclohexane in a 1000mL closed reaction kettle equipped with mechanical stirring, 4g peroxymolybdate, add Perfluoro-2-methyl-2-pentene (99%) 300g, control the reaction temperature 100 ℃, the reaction pressure is 0.8MPa, feed oxygen, react for 5 hours in total, after the reaction is over, obtain 99% purity through separation 281.9 g of perfluoro-2,3-epoxy-2-methylpentane, the molar yield was 89.2%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com