Tri-n-butylamine recycling method and recycling device used thereby

A technology of tri-n-butylamine and recovery device, applied in separation methods, chemical instruments and methods, distillation separation and other directions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

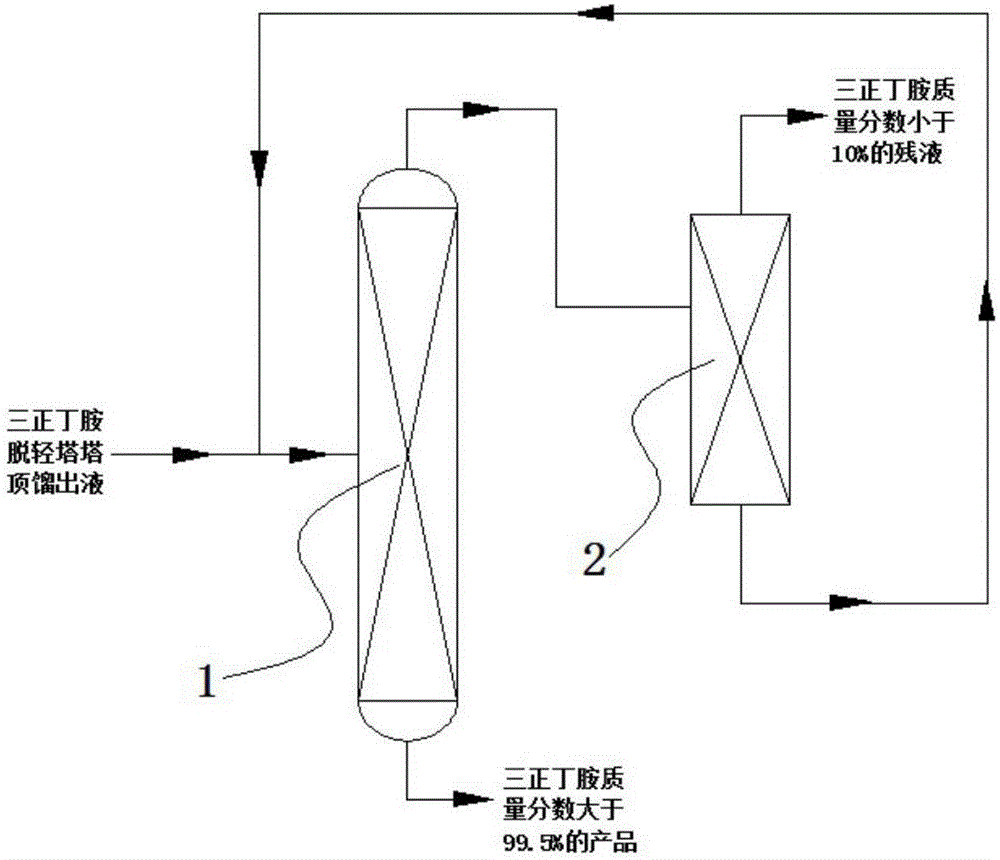

[0021] Embodiment 1, a kind of tri-n-butylamine recovery method,

[0022] At the beginning, the overhead distillate of the tri-n-butylamine light removal tower is used as a raw material, and the subsequent mixture of the tower overhead liquid of the tri-n-butylamine light removal tower and the bottom liquid of the molecular distillation tower 2 is used as a mixed raw material ; The volume ratio of the overhead distillate of the tri-n-butylamine lightening tower and the bottom liquid of the molecular distillation tower 2 in the mixed raw material is 2:1;

[0023] Raw material / mixed raw material enters rectification tower 1 from the feed port of rectification tower 1 and carries out rectification, and the tower bottom liquid that rectification tower 1 bottom obtains is tri-n-butylamine (mass fraction is greater than 99.5%), and this tri-n-butylamine Discharge from the tower bottom liquid outlet of rectifying tower 1;

[0024] The overhead distillate of rectifying tower 1 enters...

Embodiment 2

[0027] Embodiment 2, a kind of tri-n-butylamine recovery method,

[0028] The volume ratio of the overhead distillate of the tri-n-butylamine delightening tower and the bottom liquid of the molecular distillation tower 2 in the mixed raw material is 1:1;

[0029] The top pressure of rectification column 1 is 9kPa, the temperature at the bottom of the column is 98°C, and the reflux ratio is 5:1;

[0030] The tower top pressure of molecular distillation tower 2 is 50Pa, and the temperature in tower is controlled at 70 ℃;

[0031] The rest are equal to Example 1.

Embodiment 3

[0032] Embodiment 3, a kind of tri-n-butylamine recovery method,

[0033] The volume ratio of the overhead distillate of the tri-n-butylamine delightening tower and the bottom liquid of the molecular distillation tower 2 in the mixed raw material is 5:1;

[0034] The top pressure of rectification column 1 is 10kPa, the bottom temperature is 100°C, and the reflux ratio is 5:1;

[0035] The tower top pressure of molecular distillation tower 2 is 100Pa, and the temperature in tower is controlled at 75 ℃;

[0036] The rest are equal to Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com