A multi-layer circulating vertical constructed wetland system

A constructed wetland system and multi-layer circulation technology, applied in chemical instruments and methods, water/sludge/sewage treatment, biological water/sewage treatment, etc., can solve the problems of easily exceeding the standard of nitrogen and phosphorus content, single filling layer, and inconvenience. , to achieve good impurity adsorption effect, improve purification effect, and high filtration efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

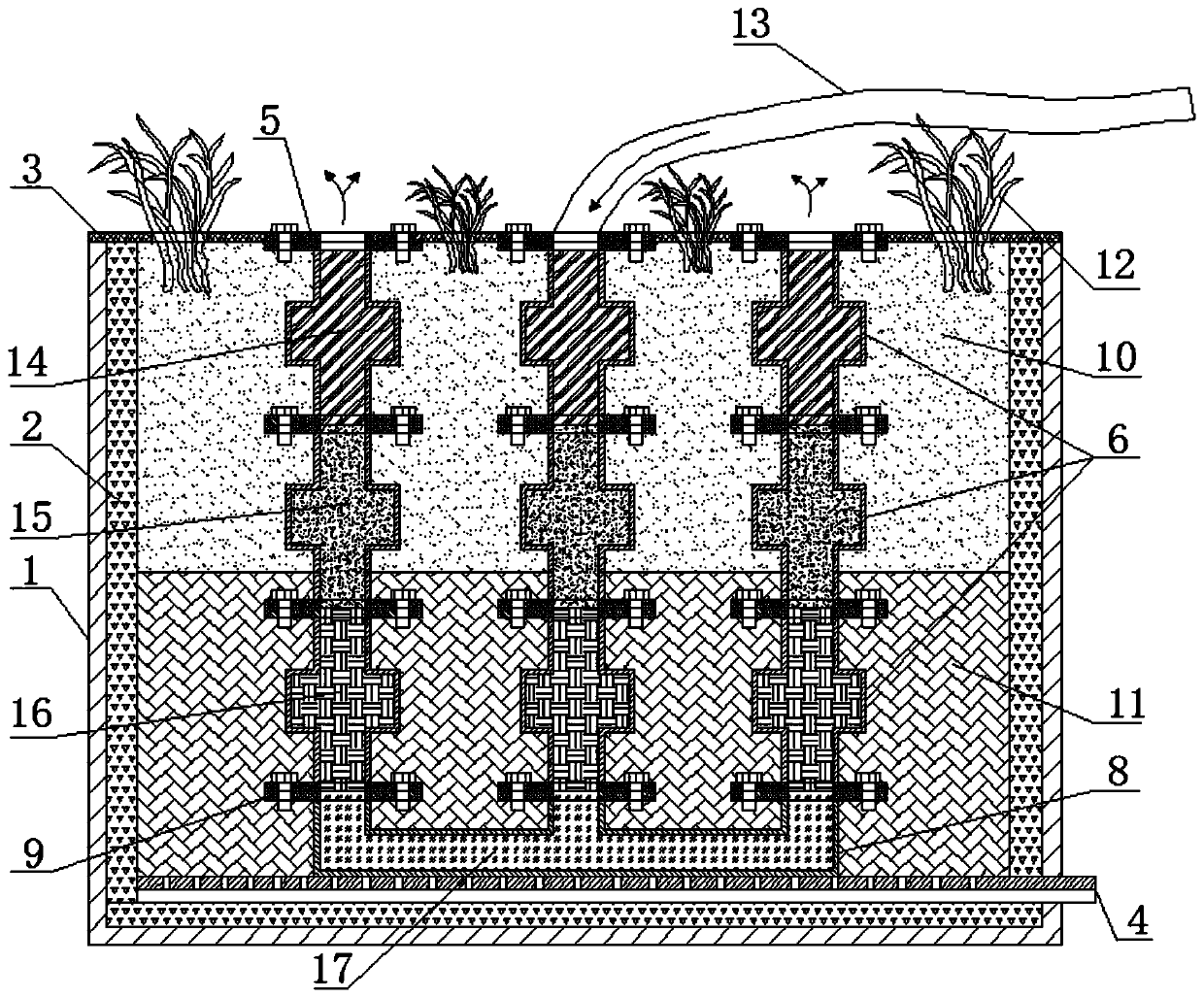

[0029] A multi-layer circulation type vertical constructed wetland system, including a wetland base unit, a multi-layer circulation unit, an aquatic plant unit and a water inlet and outlet unit. The multi-layer circulation unit is arranged inside the wetland base unit, and the aquatic plant unit is planted above the multi-layer circulation unit The water inlet and outlet units are set at the top and bottom of the multi-layer circulation unit; the wet ground base unit includes a reaction tank 1 and an impervious wall 2 laid close to the inner wall of the reaction tank 1. The reaction tank 1 is a concrete structure, and the concrete structure is used as the foundation. Strong and reliable, the anti-seepage wall 2 is made of asbestos board, which has good sealing performance and can effectively prevent water leakage.

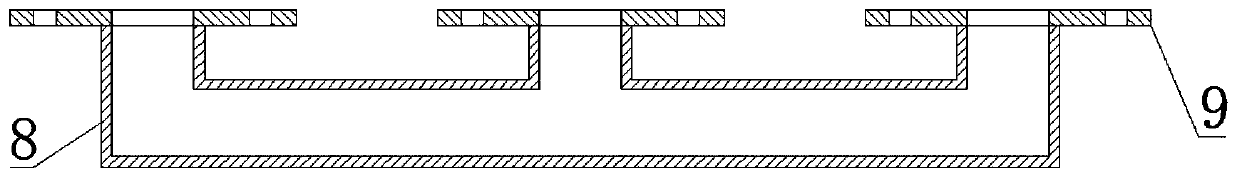

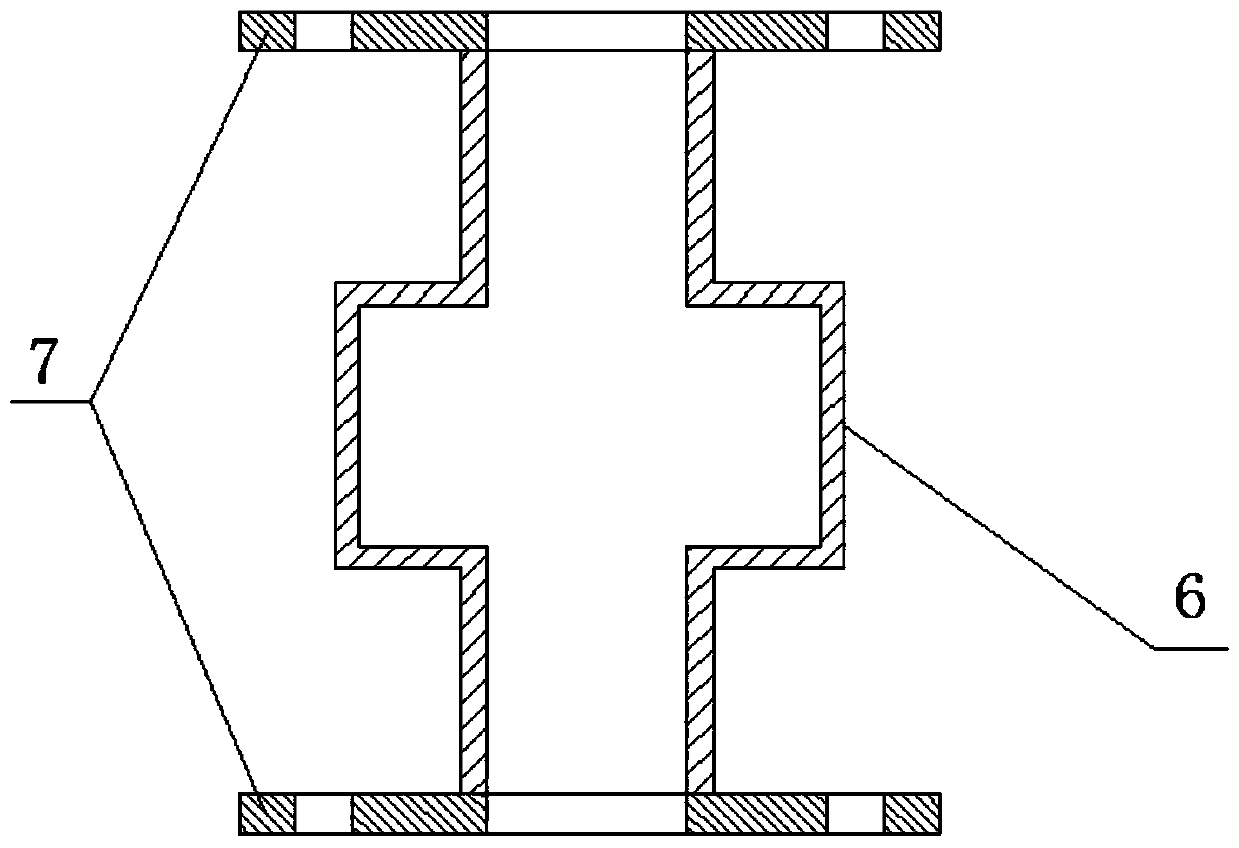

[0030] The multi-layer circulation unit includes three sets of the same circulation pipes, a set of "mountain" pipes 8, a soil layer 10 and an activated carbon layer 1...

Embodiment 2

[0034] A multi-layer circulation type vertical constructed wetland system, including a wetland base unit, a multi-layer circulation unit, an aquatic plant unit and a water inlet and outlet unit. The multi-layer circulation unit is arranged inside the wetland base unit, and the aquatic plant unit is planted above the multi-layer circulation unit The water inlet and outlet units are set at the top and bottom of the multi-layer circulation unit; the wet ground base unit includes a reaction tank 1 and an impervious wall 2 laid close to the inner wall of the reaction tank 1. The reaction tank 1 is a concrete structure, and the concrete structure is used as the foundation. Sturdy and reliable, the anti-seepage wall 2 is made of asbestos board, which has good sealing performance and can effectively prevent water leakage.

[0035] The multi-layer circulation unit includes three sets of the same circulation pipes, a set of "mountain" pipes 8, a soil layer 10 and an activated carbon layer 1...

Embodiment 3

[0039] Nitrogen and phosphorus treatment effect experiment:

[0040] Three groups of sewage experiment groups were taken out from sewage ponds in three different places, and the three groups of water from different sewage ponds were flowed into the circulation pipe of the wetland system through the inlet pipe, and the original sewage water body and the wetland system were treated separately The nitrogen and phosphorus content of the latter water body was determined, and the results are shown in Table 1 below:

[0041] Table 1

[0042]

[0043] According to the data in Table 1, the multi-layer circulation vertical constructed wetland system of the present invention has a significant purification and removal effect on nitrogen and phosphorus content, and can greatly reduce nitrogen in polluted water within an effective area. Phosphorus has a good removal effect, and the higher the nitrogen and phosphorus content in the water, the higher the removal efficiency.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com