Electromagnetic rack pushing type safety braking device of lifting device

A technology of lifting equipment and safety braking, which is applied to elevators, hoisting devices, transportation and packaging, etc., and can solve problems such as failure and reduced braking force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

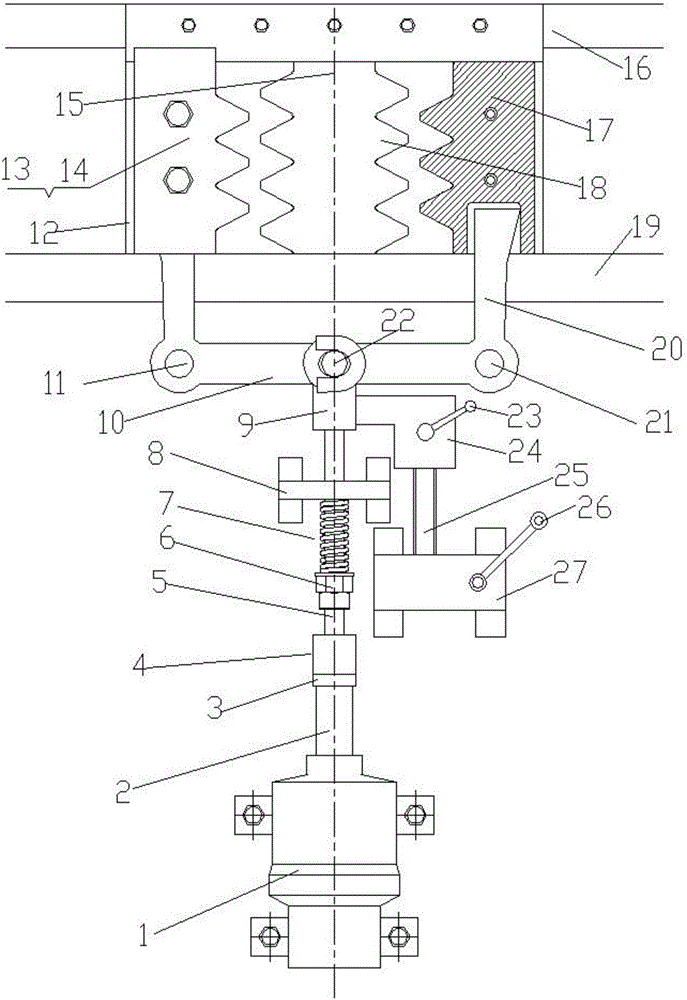

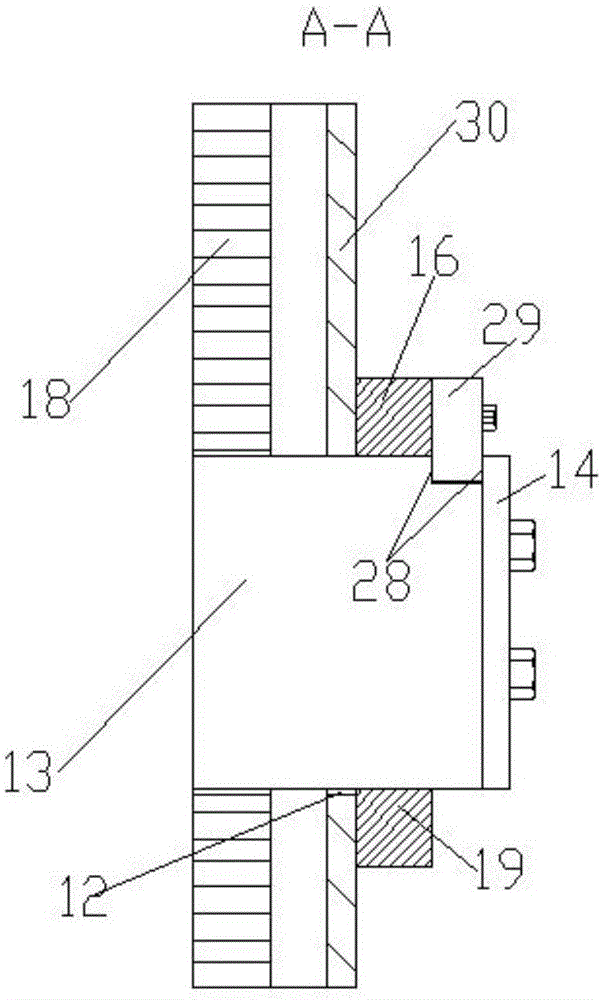

[0021] Embodiment 1, a lifting equipment equipped with an electromagnetically driven rack-type safety brake assembly directly installed on the lifting equipment car, Figure 7 It is a schematic diagram of Embodiment 1, and the drawing shows the appearance of the side of the elevator. The electromagnetically driven rack-type safety brake device is installed on the rack-and-pinion lifting equipment and is temporarily in a free position, and the lifting equipment is ready to run or is running. Condition, Figure 8 It is a schematic diagram of the situation that the electromagnetically driven rack type safety braking device of embodiment 1 brakes the lifting equipment, (the left and right described in the previous figure are viewed from the inside of the lifting equipment to the side of the lifting equipment, Figure 7 , 8 It is viewed from the outside to the side of the lifting equipment, so the left and right directions are just opposite), the electromagnetically driven rack-ty...

Embodiment 2

[0022] Embodiment 2 is a lifting device equipped with an electromagnetically driven rack-type safety brake device independent safety brake device assembly according to the present invention, Figure 9 It is a schematic diagram of embodiment 2, showing that the main body of the electromagnetic pusher 1 is in a power-off state, and the situation when the electromagnetic pusher rack type safety brake device implements braking, Figure 10 In embodiment 2, when the main body 1 of the electromagnetic pusher is in the energized state and the electromagnetically driven rack-type safety brake device is in a free position, the specific structure of the electromagnetically driven rack-type safety brake device used in the lifting equipment is a An independent safety brake device assembly that sets independent components separately and is then installed on the lifting equipment, Figure 11It is a schematic diagram of an independent safety brake assembly of the electromagnetically driven ra...

Embodiment 3

[0023] Embodiment 3, an elevator equipped with an electromagnetically propelled rack-type safety brake assembly directly installed on the elevator car, its appearance is the same as Figure 7 , Figure 8 , the working principle is the same as that described in paragraph [0021].

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com