Self-centering type torque adjusting wire winding device

A technology of torque adjustment and wire winding, which is applied in the field of automatic centering torque adjustment wire winding device, which can solve the problems of uneven wire winding force, unstable manual control, overlapping of wires, etc., to reduce manpower input, Easy to adjust, adjust the effect of reasonable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further elaborated below in conjunction with specific examples.

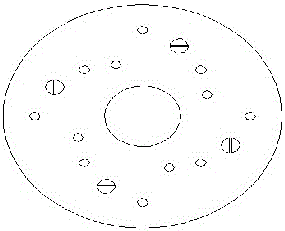

[0035] Such as figure 1 As shown, the wire reel 7 of the automatic centering type torque regulating wire winding device is fixed on the shaft of the main body support 2 through the wire reel friction connector 6 and the connecting bolt on the wire reel connector 8, and is passed through the process of pulling the wire and releasing the wire. During the process, the silk roll friction connecting part 6, the silk roll 7 and the silk roll connecting part 8 rotate simultaneously. The outer circular boss of the main body bracket 2 axially limits the small end of the wire coil friction connector 6, and a layer of friction material is coated on the outer surface of the wire coil friction connector 6 small end, and a pair of semicircular compression levers 3 It rotates around the shaft on the main body bracket, its inner surface is coated with a coating corresponding to the friction...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com