Mechanical paw

A technology of manipulator claw and drive mechanism, applied in manipulators, program-controlled manipulators, chucks, etc., can solve problems such as affecting the precision of thin-plate and disc-shaped workpieces, unable to realize 180° turning of thin-plate and disc-shaped workpieces, etc., and achieves movement guidance and reset. smooth effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The mechanical gripper of the present invention will be further described below in conjunction with the accompanying drawings and specific embodiments:

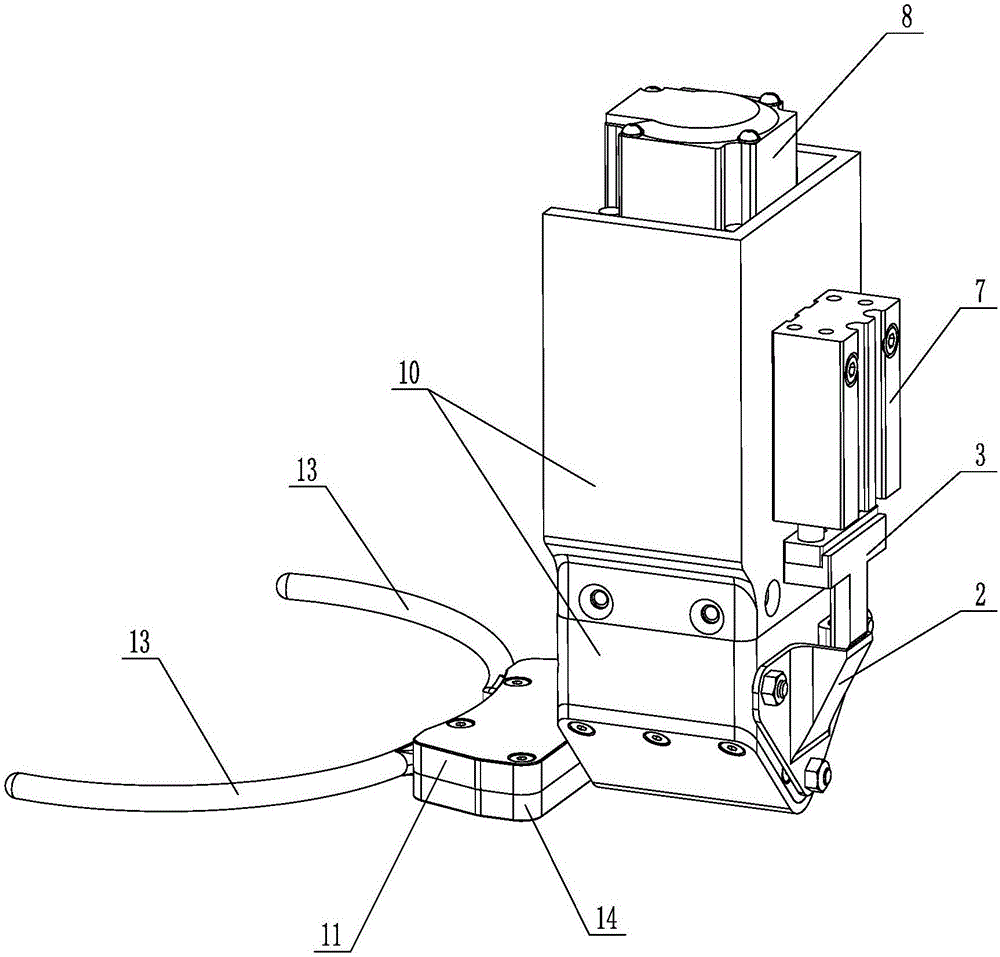

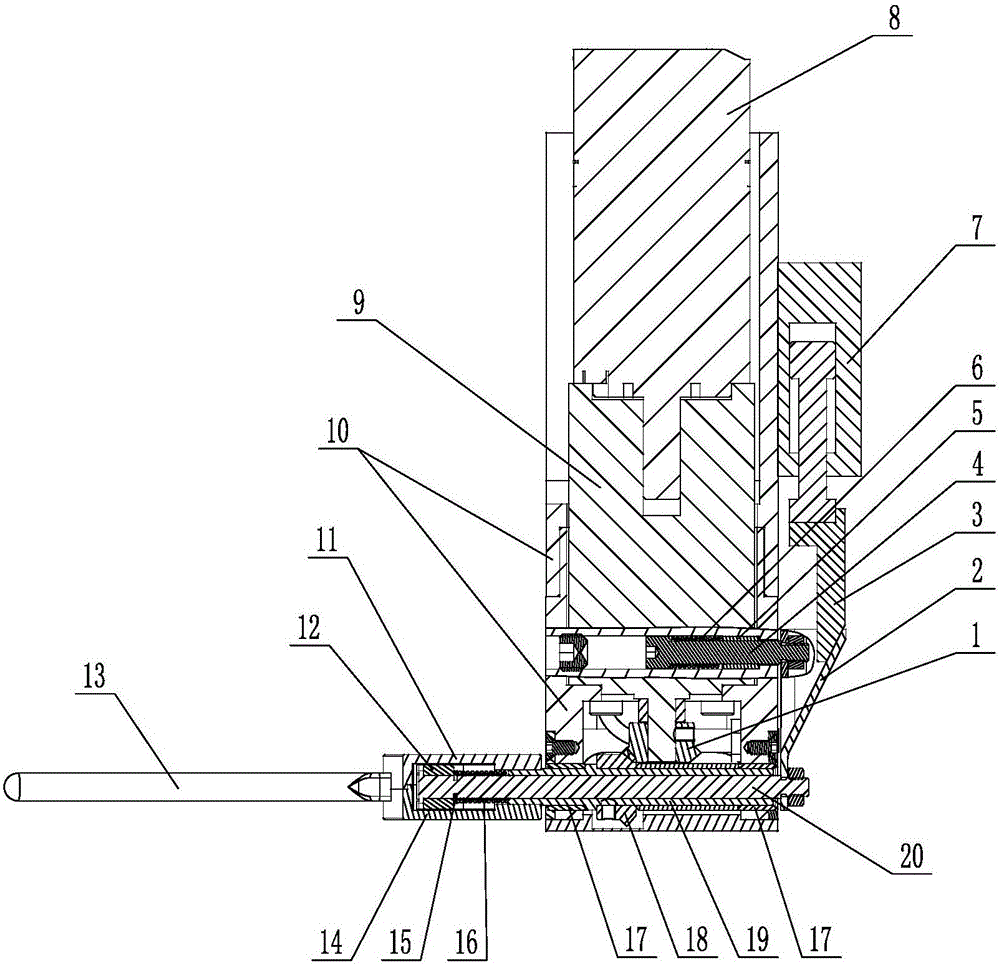

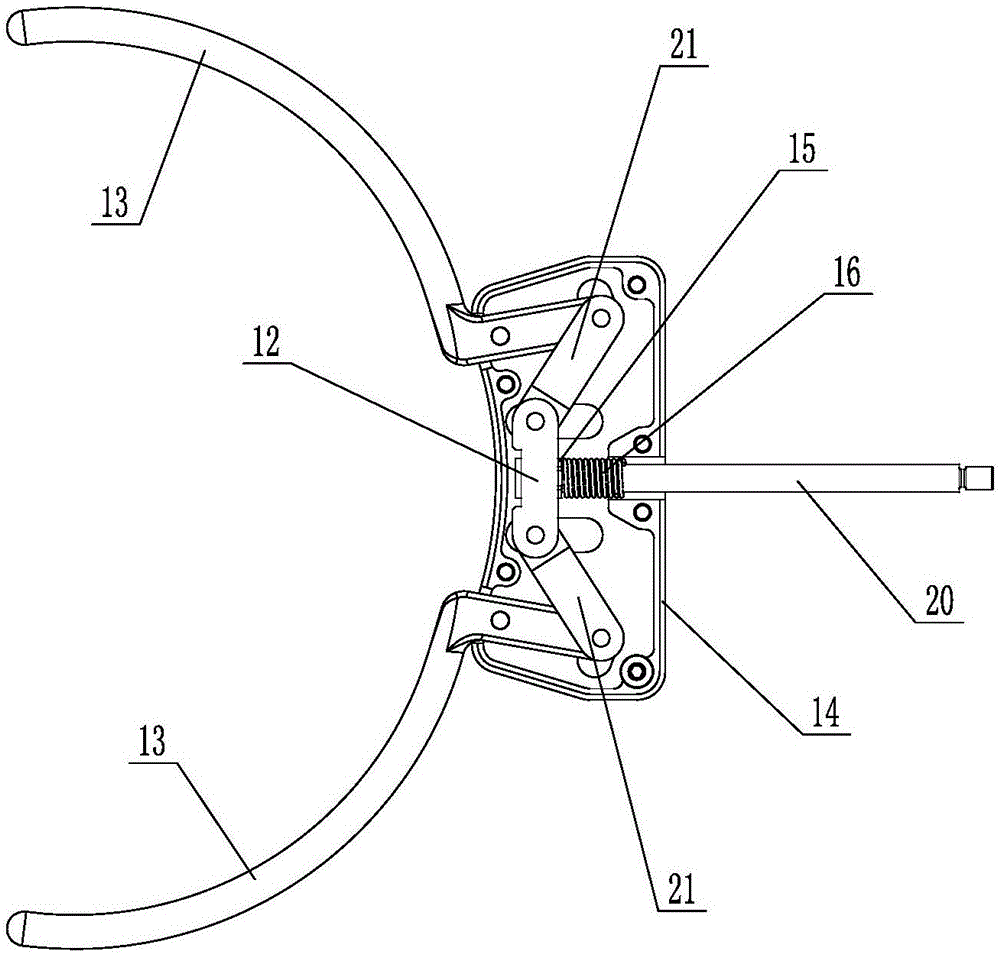

[0020] Such as Figure 1 to Figure 4 As shown, the manipulator claw of the present invention includes a bracket 10, a hollow rotating shaft 19, an upper cover plate 11 and a lower cover plate 14, the hollow rotating shaft 19 is rotatably connected with the support 10 through two first oil-free bushings 17, and the upper cover plate 11 and the The lower cover plate 14 is fastened and connected together, the upper cover plate 11 and the lower cover plate 14 are connected together with the end of the hollow rotating shaft 19, and there are two hinged joints between the upper cover plate 11 and the lower cover plate 14 for being clamped on the thin plate circle. The arc-shaped clamping fingers 13 on the side of the disc-shaped workpiece 101, the cross-section of the arc-shaped clamping fingers 13 is circular and the diamet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com