Automatic watch case disassembling and assembling equipment

A technology for automatic disassembly and assembly of watch cases, applied in metal processing equipment, metal processing, manufacturing tools, etc., can solve the problems of easily scratched watch cases, excessive force, uncontrollable rotational force, etc., to reduce worker fatigue, Improves water resistance and improves work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

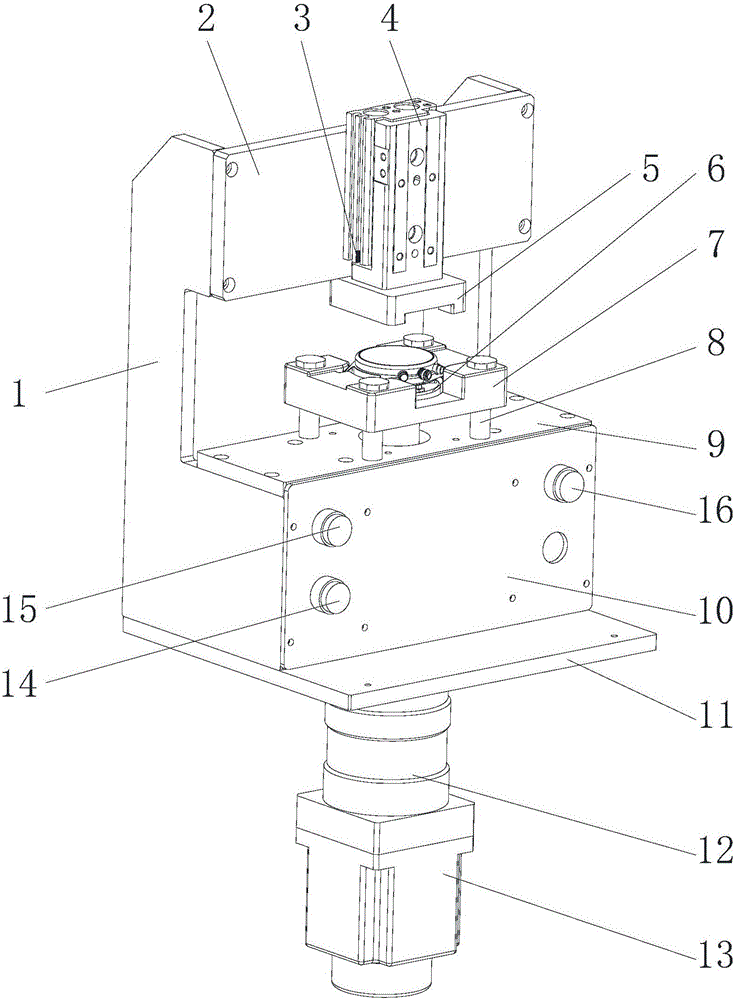

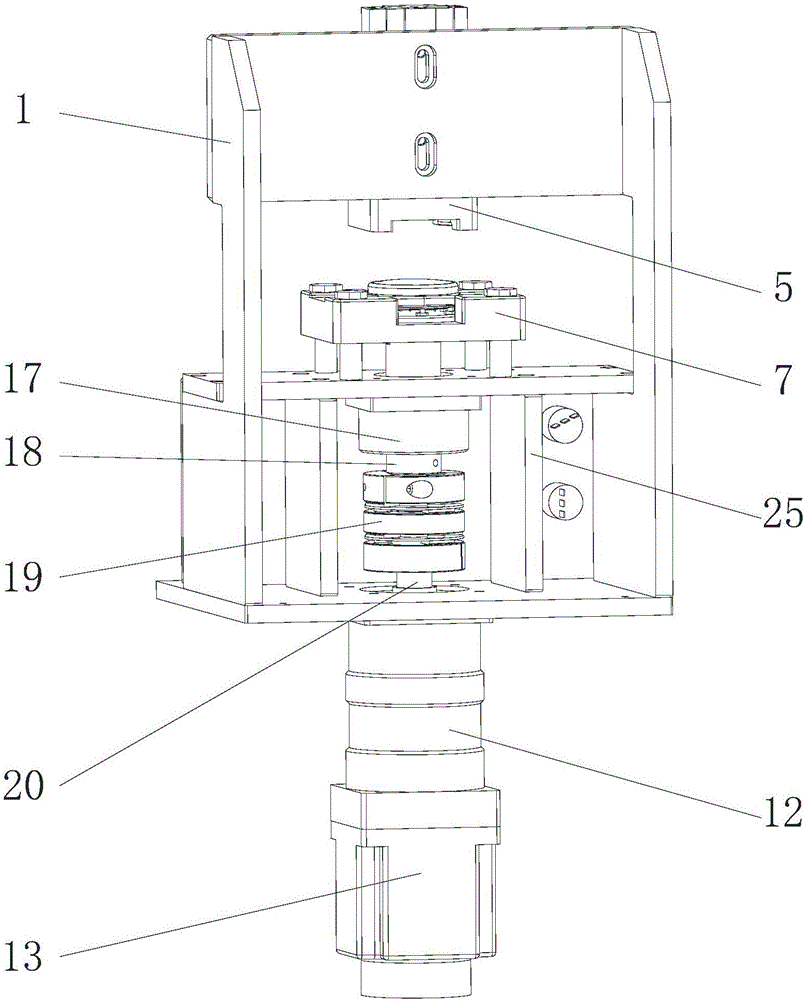

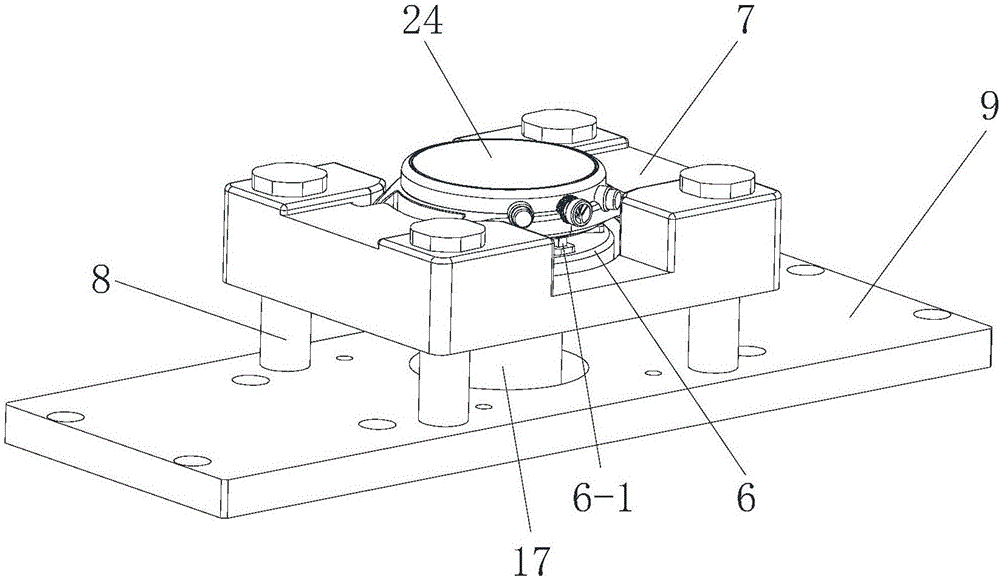

[0034] Such as figure 1 , figure 2 , image 3 , Figure 5 Shown is one of the embodiments of the present invention. In this embodiment, a watch case automatic disassembly and assembly device is provided with a frame 1, and a watch case fixing block 7 is installed and fixed in the frame 1, which is ready to be disassembled. The watch head 24 is positioned in the watch case fixing block 7, and the watch head 24 rear case is placed downward; the watch case fixing block 7 is provided with a vertical through hole, and the watch case disassembly block 6 is installed in the through hole, and the watch case The dismounting block 6 can rotate relative to the watch case fixing block 7 , and the watch case dismounting block 6 is preferably designed in a disk shape and rotates around its own axis.

[0035] The watch case dismounting block 6 is provided with some upward positioning claws 6-1, and the positioning claws 6-1 stretch into the draw-in groove of the meter head 24 rear shell,...

Embodiment 2

[0054] In this embodiment, the difference from Embodiment 1 is that a bearing is provided in the vertical through hole of the watch case fixing block 7 to support the rotation of the watch case dismounting block 6, and the bearing can be installed in a radial support manner. Such a design can improve the stability of the rotation of the case disassembly block 6 and improve the disassembly quality.

[0055] Other structures of the watch case automatic dismounting device in this embodiment are the same as those in Embodiment 1, and will not be described again here.

Embodiment 3

[0057] In this embodiment, the difference from Embodiment 1 is that the spacing between the positioning claws 6-1 can be automatically adjusted to adapt to different types of meter back cases. Such a design can expand the applicability of the watch case dismounting block 6, and facilitate dismounting and assembling of various watch cases.

[0058] In order to achieve this technical purpose, a guide groove can be designed for each positioning claw 6-1 in the watch case dismounting block 6, the direction of the guide groove is arranged along the radial direction of the dismounting block 6, and a spring in the horizontal direction is arranged in the guide groove The positioning claw 6-1 is supported, so as to realize the self-adaptive function of the positioning claw 6-1.

[0059] Other structures of the watch case automatic dismounting device in this embodiment are the same as those in Embodiment 1, and will not be described again here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com