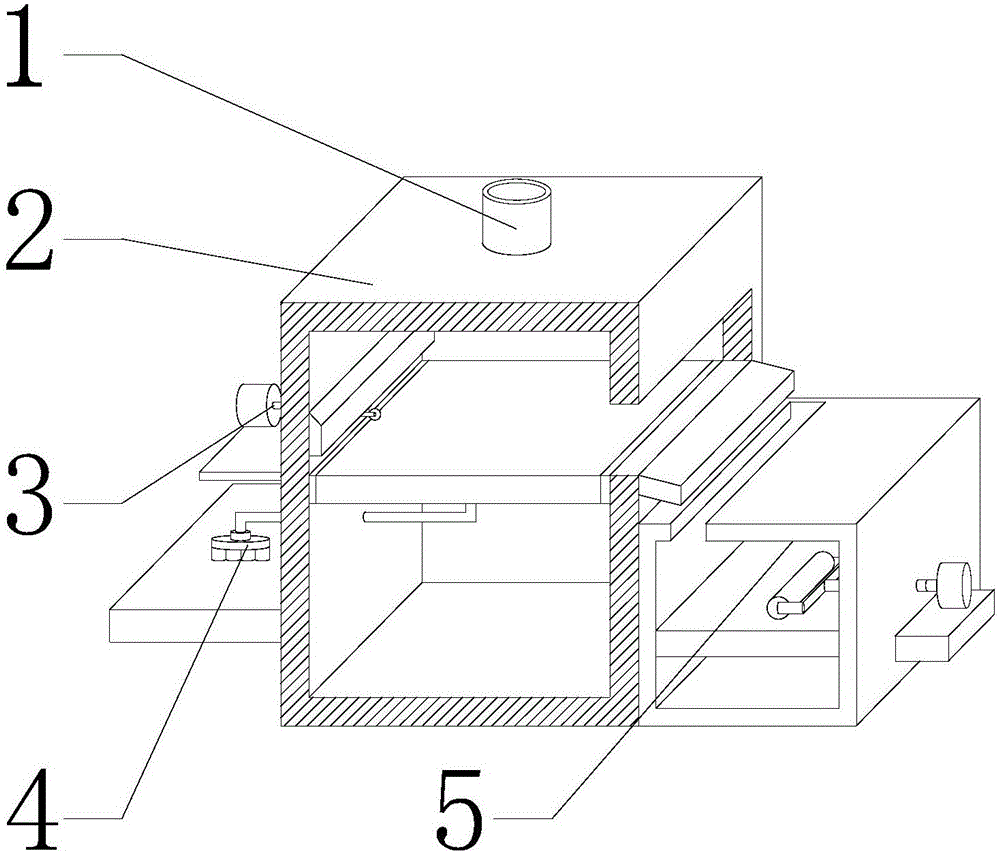

Material selecting device for building material aggregates

A technology for building material granules and material selection, applied in the direction of solid separation, filter screen, grille, etc., can solve the problems of reducing the service life of the machine, long working time, increasing production investment, etc., to reduce the frequency of downtime and reduce the working time. , the effect of prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

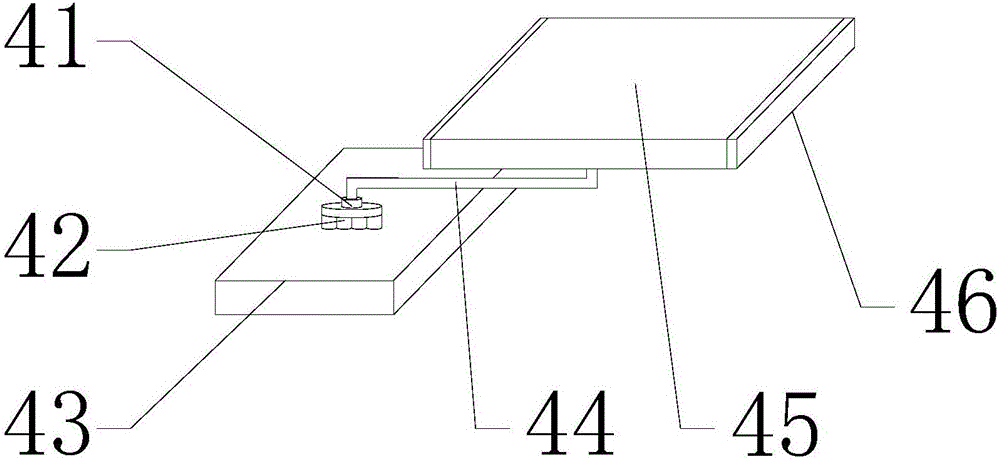

[0026] Specific implementation method: when the staff needs to screen the raw material, the staff pours the raw material into the feed pipe 1, and then the raw material leaves the feed pipe 1 and enters the box body-2 and falls on the upper end surface of the filter screen-45 , then the staff starts the vibrating machine 41, the vibrating machine 41 works to drive the connecting rod 44 to vibrate up and down, the connecting rod 44 vibrates up and down to drive the filter screen one 45 to vibrate up and down, the filter screen one 45 vibrates up and down to drive the raw material to vibrate up and down, and then the raw material has a smaller volume The raw material leaves the filter screen one 45 and falls on the inner bottom of the casing one 2, and the raw material with larger volume in the raw material is then left on the filter screen one 45 upper end face, and this design is sustainable sieve material.

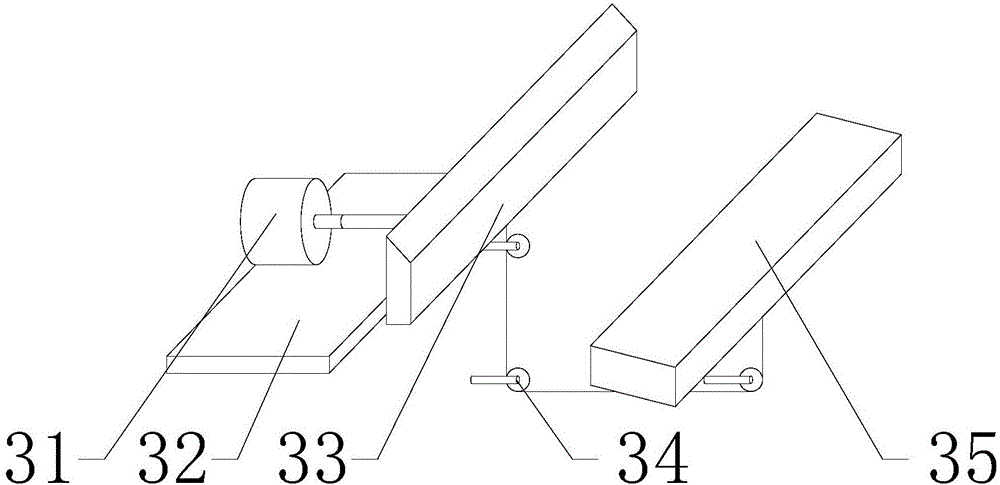

[0027] When the bulky raw materials on the upper end surface of the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com