Double-level revolution and rotation mixing machine

A mixing machine and double-stage technology, applied in the field of mixing machines, double-stage male-autonomous two-turn mixing machines, can solve the problems of difficult mixing of viscous materials, shorten mixing time, reduce mixing dead angles, and solve difficult problems. mixed effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

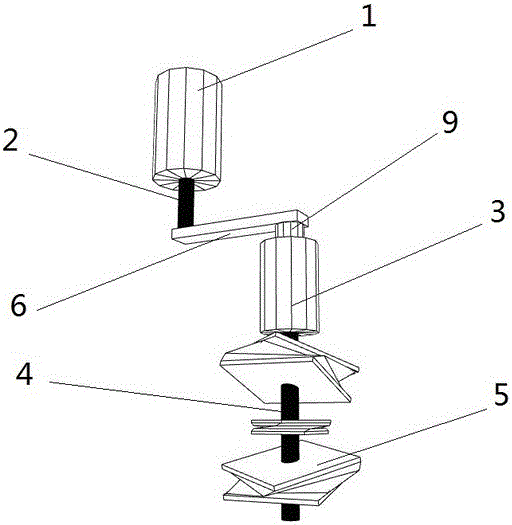

[0021] Embodiment 1 refers to figure 1 , the present embodiment provides a double-stage public-automatic two-rotation stirring machine, including a first-stage stirrer and a second-stage stirrer; the first-stage stirrer includes a first stirring motor 1 and a transmission component, and the first stirring motor 1 includes The first transmission shaft 2, the transmission parts are fixedly arranged on the first transmission shaft 2; the second stage mixer comprises a second stirring motor 3, and the second stirring motor 3 comprises a second transmission shaft 4; the second stirring motor 3 passes through a connecting base The seat 9 is fixed on the transmission part; the rotation axis of the second transmission shaft 4 is staggered from the rotation axis of the first transmission shaft 2 ; the blade 5 is arranged on the second transmission shaft 4 . The transmission part is a transmission connecting rod 6 , the first transmission shaft 2 is connected to one end of the transmiss...

Embodiment 2

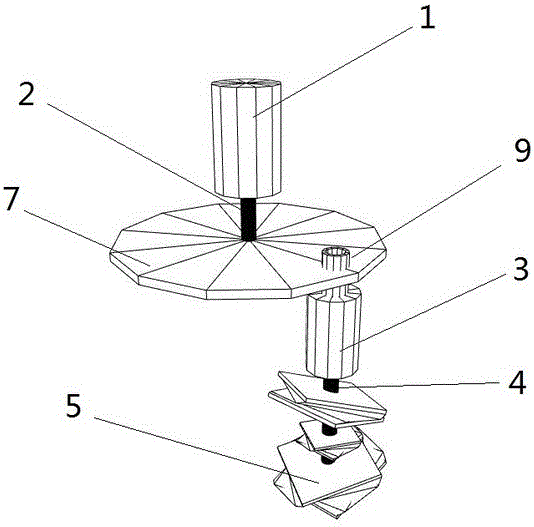

[0022] With reference to Embodiment 2, this embodiment provides another double-stage public self-rotating mixing machine, whose structure is roughly the same as that provided in Embodiment 1, including a first-stage agitator and a second-stage agitator; the first-stage The stirrer comprises a first stirring motor 1 and a transmission part, the first stirring motor 1 comprises a first transmission shaft 2, and the transmission part is fixedly arranged on the first transmission shaft 2; the second stage stirrer comprises a second stirring motor 3, and the second stirring motor 3 includes the second transmission shaft 4; the second stirring motor 3 is fixed on the transmission part through a connection base 9; the rotation axis of the second transmission shaft 4 is staggered from the rotation axis of the first transmission shaft 2; it is located on the second transmission shaft 4 Blades 5 are provided. The transmission disk is a perfect circular transmission disk 7, the first tra...

Embodiment 3

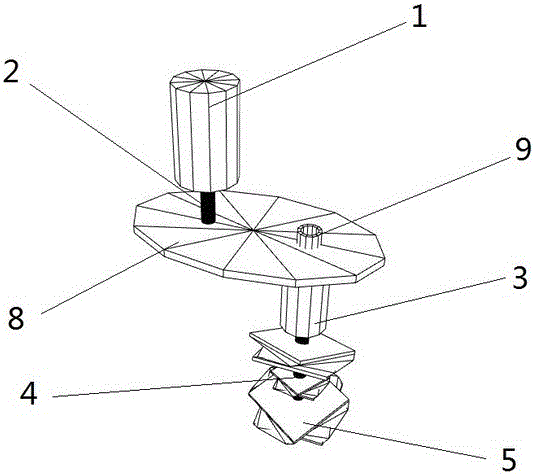

[0023] Embodiment 3 The mechanical structure of the two-stage public-automatic two-rotation stirring mechanism introduced in this embodiment is slightly different from that described in Embodiment 1, including a first-stage stirrer and a second-stage stirrer; the first-stage stirrer includes a first stirring motor 1 and the transmission part, the first stirring motor 1 comprises the first transmission shaft 2, and the transmission part is fixedly arranged on the first transmission shaft 2; the second stage mixer comprises the second stirring motor 3, and the second stirring motor 3 comprises the second transmission shaft 4; the second stirring motor 3 is fixed on the transmission part through a connection base 9; the rotation axis of the second transmission shaft 4 is staggered from the rotation axis of the first transmission shaft 2; blades 5 are arranged on the second transmission shaft 4. The transmission disk is an elliptical transmission disk 8, the first transmission shaf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com