Liquid-absorption core of grid structure and manufacturing process of liquid-absorption core

A grid structure and liquid-absorbing core technology, which is applied in the field of health care products, can solve the problems of reducing the utilization rate of polymers, prolonging the production cycle, and bottlenecks in production efficiency, so as to reduce the amount of hot melt adhesive, shorten the production cycle, and improve production. speed effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The specific implementation manners of the present invention will be further described below in conjunction with the drawings and examples. The following examples are only used to illustrate the technical solution of the present invention more clearly, but not to limit the protection scope of the present invention.

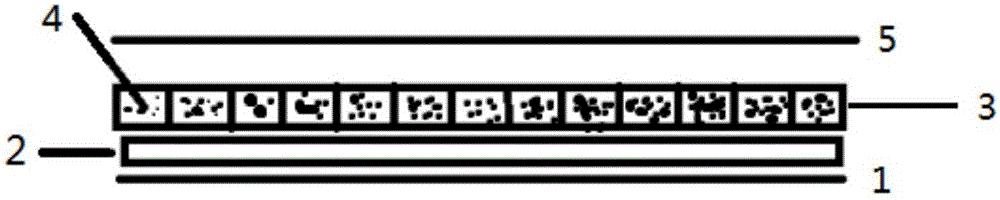

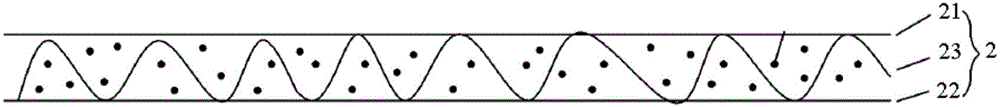

[0034] Such as figure 1 As shown, the present invention is a liquid-absorbent core with a grid structure, and the core includes a grid structure support frame 3 made of a flexible material, and the mesh of the grid structure support frame 3 is filled with granular The superabsorbent resin 4 has a flow-guiding layer 2 attached below the grid structure support frame 3, a lower non-woven fabric layer 1 is attached below the flow-guidance layer 2, and an upper layer is attached on the grid structure support frame 3. Non-woven layer 5.

[0035] A preferred embodiment of the present invention is that the grid structure support frame 3 made of flexible material ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com