Method for Destemming and Redrying Processing of Turkish Semi-oriental Tobacco Leaf

A semi-oriental tobacco, threshing and redrying technology, which is applied in the fields of processing tobacco, tobacco, and preparing tobacco. It can solve the problems of high stem content, large loss of flavor characteristics, and low rate of large and medium tobacco leaves, and achieve uniform moisture regain. , Reduce the effect of stem sticks and the probability of mildew

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

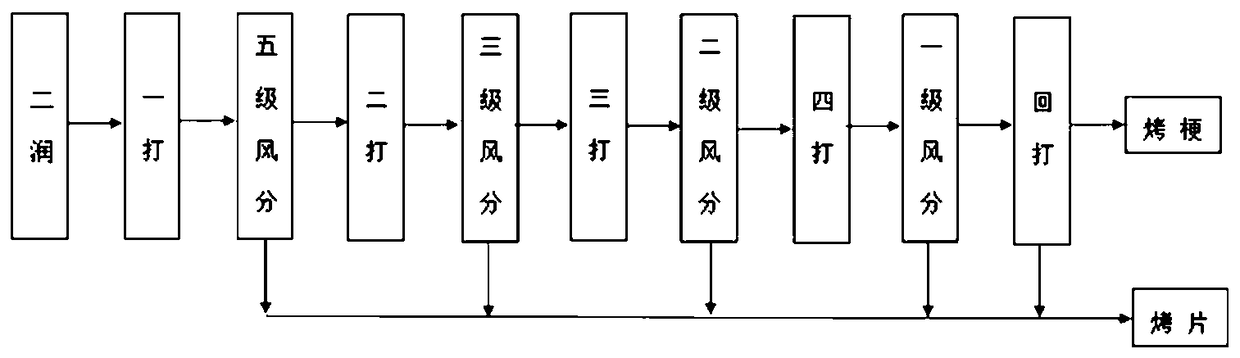

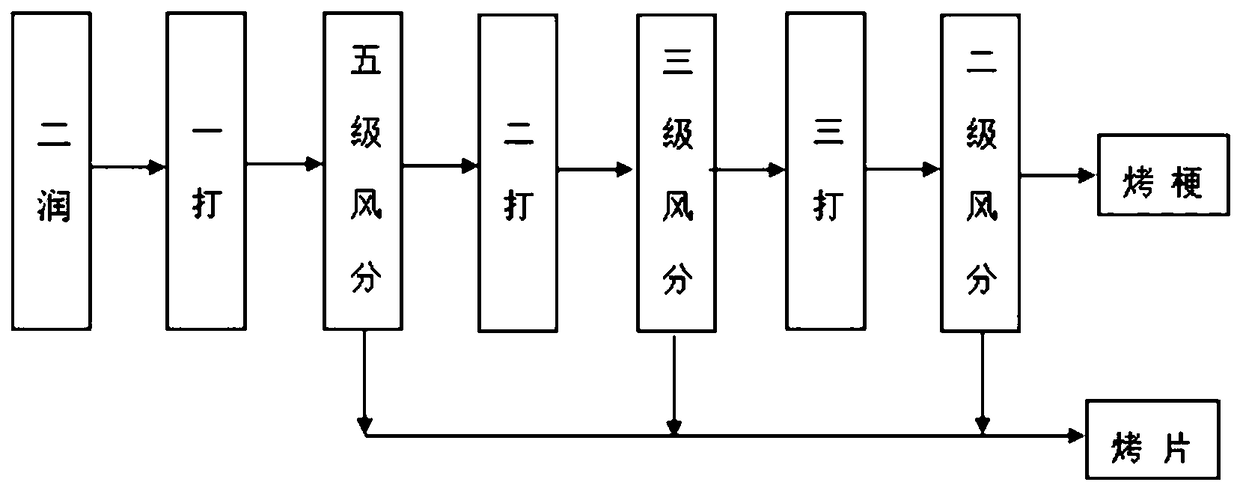

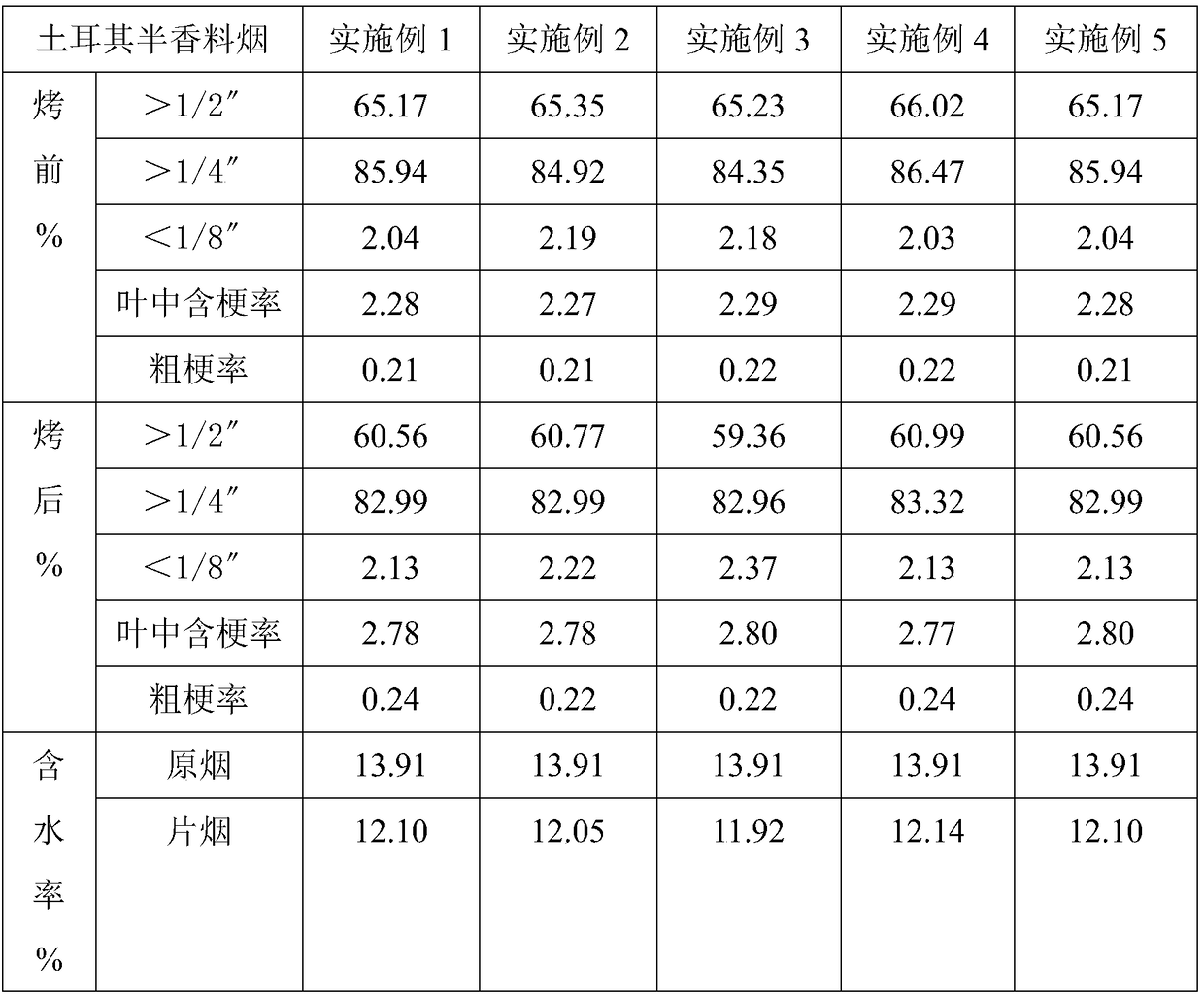

[0028] This example provides a method for destemming and redrying processing of Turkish semi-oriental tobacco (Turkish CU (Xiang 50)) tobacco leaves. The leaf threshing and redrying equipment is used for destemming of tobacco leaves. The process flow is shown in the attached figure 2 The steps shown in turn include second moistening (leaf moistening), one dozen (threshing leaves), fifth-level wind classification, second dozen, third-level wind separation, three dozen, and second-level wind separation steps. The obtained tobacco stems are roasted, and the The tobacco leaves obtained by the five-level air classification, the third-level wind classification, and the second-level wind classification are processed by roasting and slicing.

[0029] In the leaf moistening stage, the tobacco leaf material flow rate is controlled at about 6000kg / h, and the temperature is not higher than 50°C, and the moisture regain treatment of the tobacco leaves is carried out, so that the moisture c...

Embodiment 2

[0032] This example provides a method for destemming and redrying processing of Turkish semi-oriental tobacco (Turkish CU (Xiang 50)) tobacco leaves. The leaf threshing and redrying equipment is used for destemming of tobacco leaves. The process flow is shown in the attached figure 2 The steps shown in turn include second moistening (leaf moistening), one dozen (threshing leaves), fifth-level wind classification, second dozen, third-level wind separation, three dozen, and second-level wind separation steps. The obtained tobacco stems are roasted, and the The tobacco leaves obtained by the five-level air classification, the third-level wind classification, and the second-level wind classification are processed by roasting and slicing.

[0033] In the leaf moistening stage, the tobacco leaf material flow rate is controlled at about 6000kg / h, and the temperature is not higher than 48°C, and the moisture regain treatment of the tobacco leaves is carried out, so that the moisture c...

Embodiment 3

[0036] This example provides a method for destemming and redrying processing of Turkish semi-oriental tobacco (Turkish CU (Xiang 50)) tobacco leaves. The leaf threshing and redrying equipment is used for destemming of tobacco leaves. The process flow is shown in the attached figure 2The steps shown in turn include second moistening (leaf moistening), one dozen (threshing leaves), fifth-level wind classification, second dozen, third-level wind separation, three dozen, and second-level wind separation steps. The obtained tobacco stems are roasted, and the The tobacco leaves obtained by the five-level air classification, the third-level wind classification, and the second-level wind classification are processed by roasting and slicing.

[0037] In the leaf moistening stage, the tobacco leaf material flow rate is controlled at about 6000kg / h, and the temperature is not higher than 52°C, and the moisture regain treatment of the tobacco leaves is carried out, so that the moisture co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com