A high-efficiency energy-saving leaf threshing air separation process and equipment

A high-efficiency and energy-saving technology for leaf thumping and air separation. It is used in solid separation, air flow to separate solids from solids, and tobacco. It can solve problems such as not being able to meet new processes, achieve process and equipment layout specifications, and is not easy to block materials. , Improve the effect of large and medium film rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

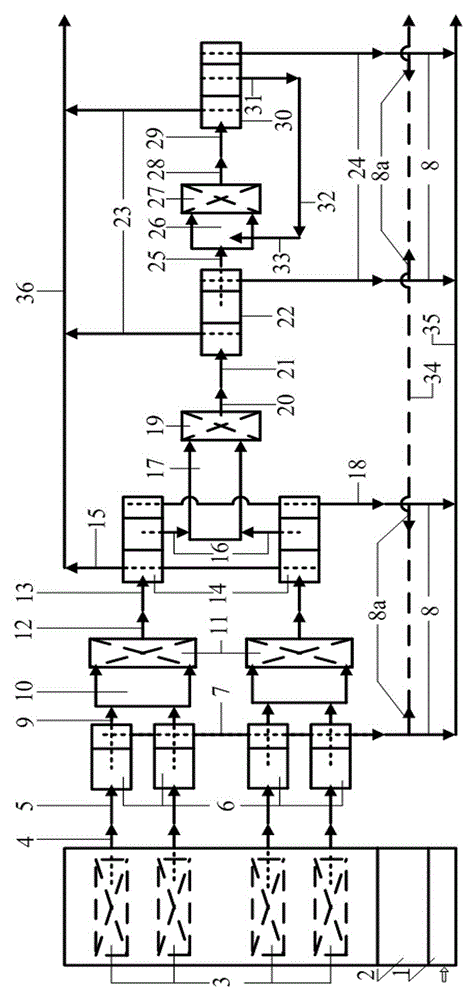

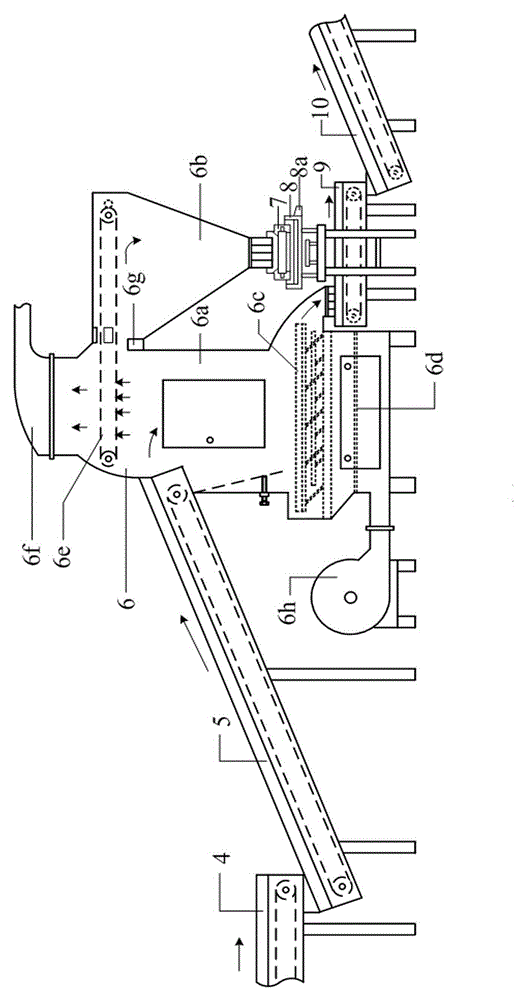

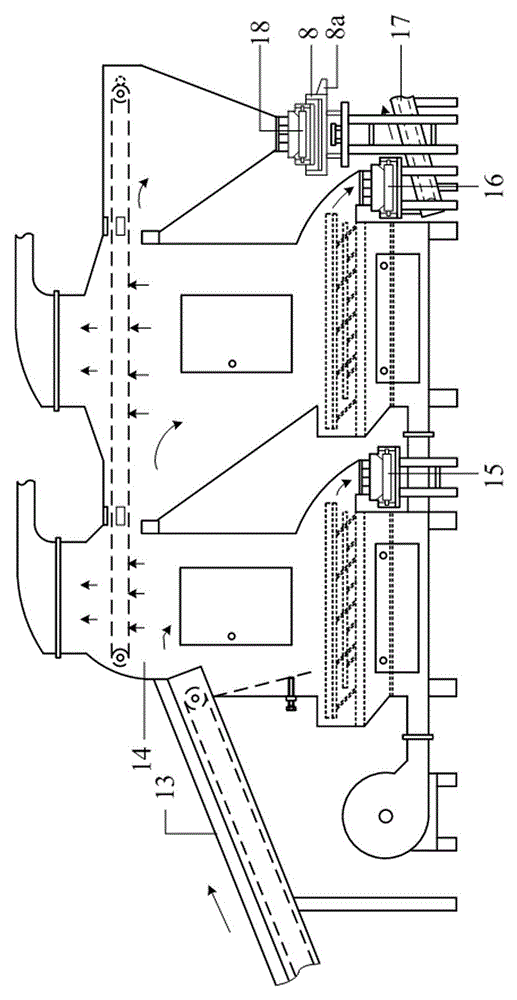

[0039] Such as figure 1 As shown, the entire high-efficiency and energy-saving defoliating air separation process and equipment assembly are composed of a scraper feeder 1, a bin feeder 2, a first-stage defoliating unit 3 fed in proportion, and a defoliating machine discharge conveyor belt 4 , high-speed conveyor belt 5, air-pressure double-cabin air sub-machine 6, one-wind blade discharge conveyor belt 7, vibrating screen 8, shredded tobacco sheet outlet 8a, stalk blade conveyor belt 9, and a wider conveyor belt at the leaf-threshing unit entrance 10. The second-stage leaf-threshing unit 11, the leaf-threshing machine outlet vibrating groove 12, the high-speed conveyor belt 13, the air pressure type three-storey air sub-machine 14, the stalk discharge conveyor belt 15, the stem blade conveyor belt 16, the leaf-thresher inlet Wider conveyer belt 17, second wind sub-blade discharge conveyer belt 18, third-stage leaf topper 19, leaf topper discharge vibrating trough 20, high-sp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com