Structured detergent particles and granular detergent compositions containing the same

A structured detergent, granular technology, applied in the direction of detergent composition, surface active detergent composition, inorganic/elemental detergent composition, etc., can solve the problem of total surfactant content or surfactant activity limitation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

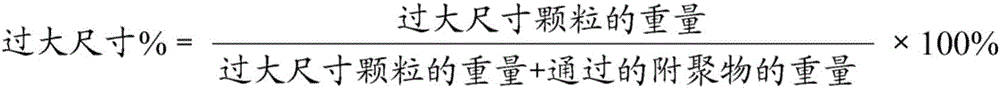

[0086] Example 1: Showing the percentage of oversized particles produced using sodium tripolyphosphate (STPP) or sodium carbonate comparison test

[0087] 1.1. WO9804670 discloses in Example VIII a granular detergent composition comprising about 30% HLAS, 36% sodium carbonate, 29% sodium tripolyphosphate (STPP) and 5% hydrophilic silica . It has been surprisingly and unexpectedly found that structured detergent particles according to the invention comprising significantly higher amounts of sodium carbonate but little or no STPP lead to the formation of less undesirable oversized particles.

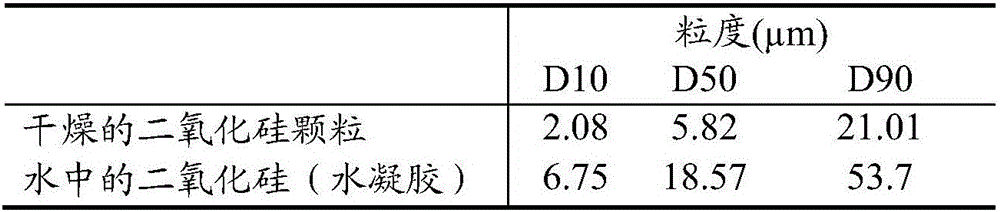

[0088] 1.2. A first sample ("comparative sample") was prepared by 1) 33.98 g of precipitated silica powder with a particle size distribution Dw50 of about 6 microns (commercially available under the trade designation SN340 from Evonik Industries AG) and 2) 244.66 grams of ground sodium carbonate with a particle size distribution Dw50 of about 20-25 microns and 3) 197.09 grams of STPP ...

Embodiment 2

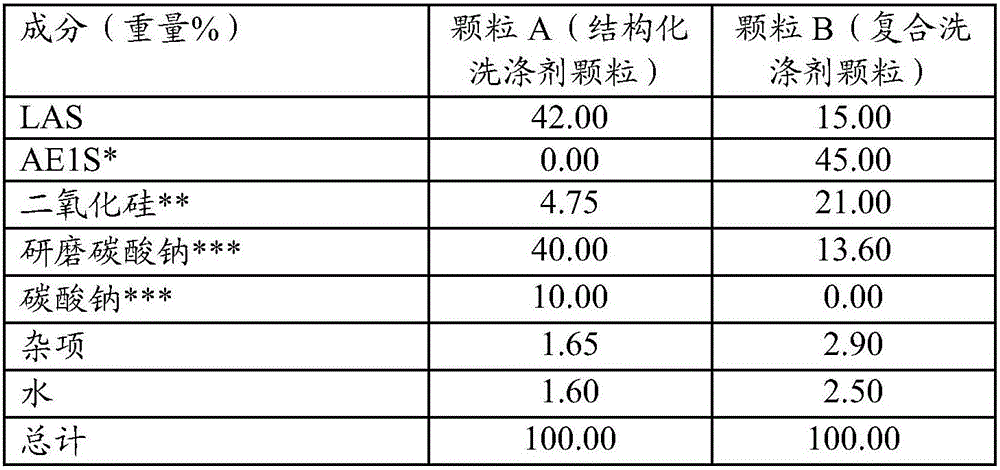

[0100] Example 2: Structured detergent granules and composite detergent granules

[0101]Exemplary structured detergent granules according to the present invention were prepared by mixing 1) 34 grams of precipitated silica powder (commercially available from Madhu Silica PVT., Ltd.) with a particle size distribution Dw50 of about 5 microns and 2) 311.4 grams of ground sodium carbonate with a particle size distribution Dw50 of about 20-25 um and 77.9 grams of sodium carbonate were weighed into a batch Tilt-a-pin mixer (from Processall) with the mixer running at 700 rpm Mix down for about 2 seconds; 3) inject 276.7 grams of 96% active HLAS into the mixer at a rate of about 25.2 ml / sec until all the paste is added; 4) then allow the mixture to mix for 2 seconds before stopping; a total of about 679.7 Grams of final product were prepared as Granule A (20.3 grams of carbon dioxide produced and lost) using the composition described in Table IV.

[0102] Exemplary composite deterg...

Embodiment 3

[0109] Example 3: Exemplary Formulations of Granular Laundry Detergent Compositions

[0110]

[0111]

[0112]

[0113] *The base granule is a spray-dried detergent granule comprising about 12-13% by weight LAS, about 70-75% by weight

[0114] % sodium sulfate, about 8-10% by weight silicate and less than 3% by weight moisture.

[0115] All enzyme levels are expressed as carpet active enzyme protein per 100 g of detergent composition.

[0116] The surfactant component is available from BASF (Ludwigshafen, Germany) Shell Chemicals (London, UK); Stepan (Northfield, Ill., USA); Huntsman (Huntsman, Salt Lake City, Utah, USA); Clariant (Sulzbach, Germany)

[0117] Sodium tripolyphosphate is available from Rhodia (Paris, France).

[0118] Zeolites are available from Industrial Zeolites (UK) Ltd (Grays, Essex, UK).

[0119] Citric acid and sodium citrate are available from Jungbunzlauer, Basel, Switzerland.

[0120] NOBS is sodium nonanoyloxybenzenesulfonate suppli...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size distribution | aaaaa | aaaaa |

| particle size distribution | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com