Coil rack assembly of electromagnetic relay

A technology of electromagnetic relays and coil formers, applied in electromagnetic relays, detailed information of electromagnetic relays, relays, etc., can solve the problems of pulling out the lead pins, affecting the high power of the relay, and difficult to meet the strength of the coil lead pins. , to achieve the effect of increasing the contact load capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

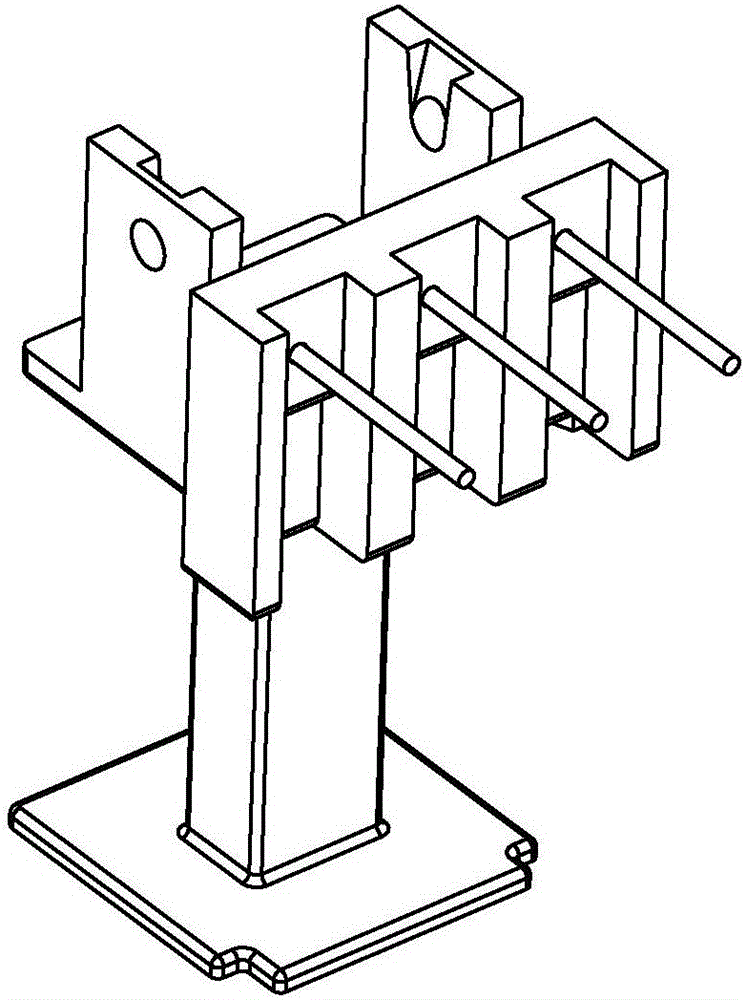

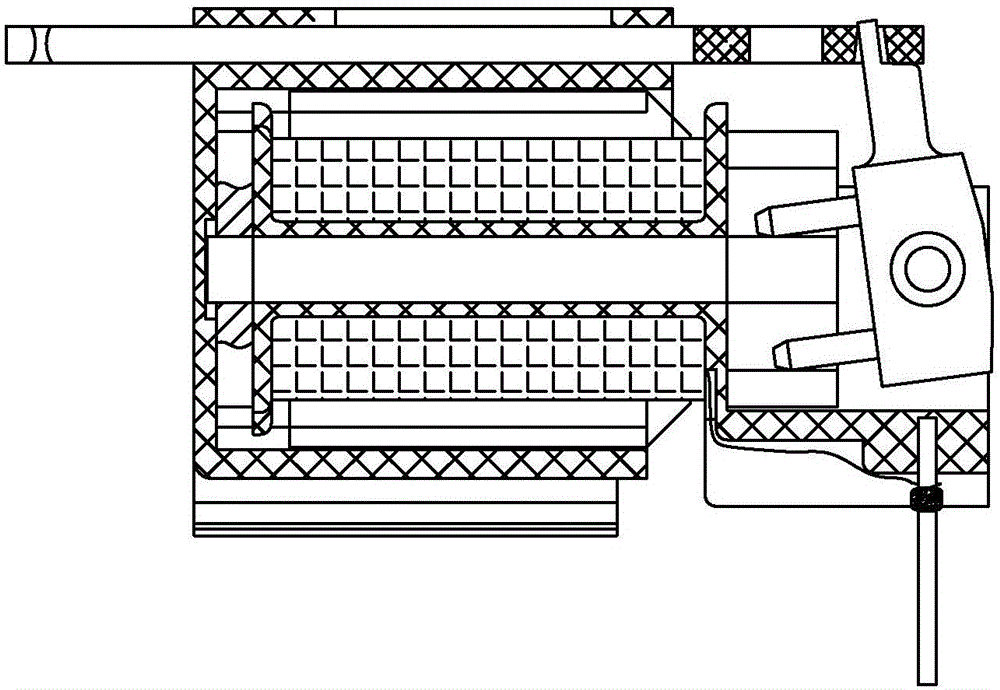

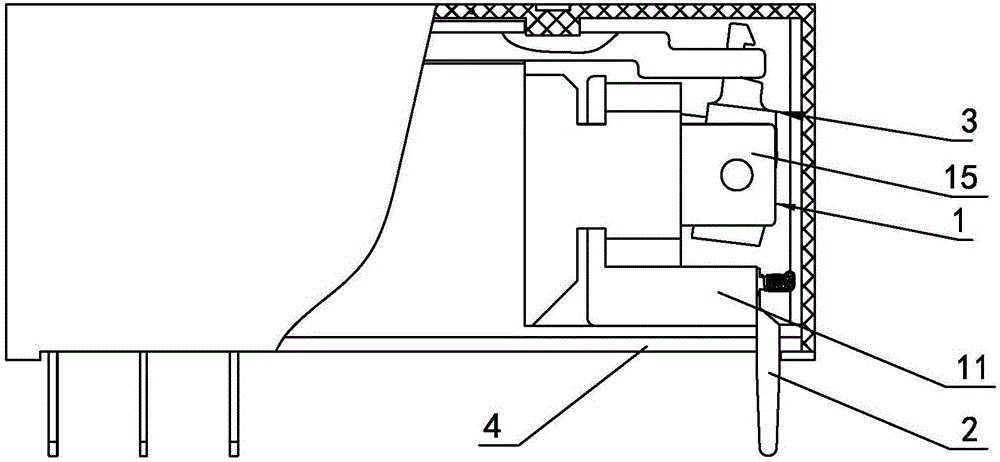

[0024] Embodiment one, such as Figure 3 to Figure 6 As shown, a coil frame assembly of an electromagnetic relay includes a coil frame 1 and a lead pin 2, and the coil frame 1 includes a lead pin mounting seat 11, a bobbin 12, and first flanges 13 and 12 arranged at both ends of the bobbin 12 The second flange 14, the lead foot mounting seat 11 is integrally connected to the lower end of the first flange 13, and the left and right sides of the first flange 13 are integrally provided with a left mounting plate 15 and a right mounting plate for installing the magnetic package 3 respectively. Plate 16, the length a of the lead pin mounting seat 11 is less than the length b of the left mounting plate 15 and the right mounting plate 16, and two first lead wire slots 17 with one end connected to the bobbin 12 are provided on the inner side of the first flange 13 , the other end of each first lead groove 17 is connected with one end of the corresponding second lead groove 18 arranged...

Embodiment 2

[0025] Embodiment two, such as Figures 7 to 10 As shown, its technical features are the same as those in Embodiment 1, the difference is that the number of second lead slots 18 is three, the clamping part 21 is not T-shaped as a whole, and the vertical section of the lead-out pin 1 is the same as the vertical section of the clamping part 21. Or the vertical section of the end wire part 22 is perpendicular to each other. In this way, after the clamping part 21 of the lead pin 2 is clamped with the slot 111, the contact area perpendicular to the clamping part 21 and the lead pin 2 reaches the maximum, so that the lead pin 2 and the lead pin 2 are perpendicular to each other. The installation and connection of the coil frame 1 is stable, and the insertion and extraction force that the lead pin 2 can withstand is also maximized.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com