Method for detecting characteristics of electronic product

A detection method and a technology of electronic products, which are applied to the components of electrical measuring instruments, measuring devices, and measuring electrical variables, etc., can solve the problems of high detection cost and small application range, and achieve high efficiency, fast and convenient detection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] A method for detecting characteristics of an electronic product, comprising the steps of:

[0019] S1) Determine the detection terminal of the detection device according to the port model of the product to be tested;

[0020] S2) Determine the installation position and the number of detection terminals according to the port position and number of the product to be tested;

[0021] S3) installing detection terminals;

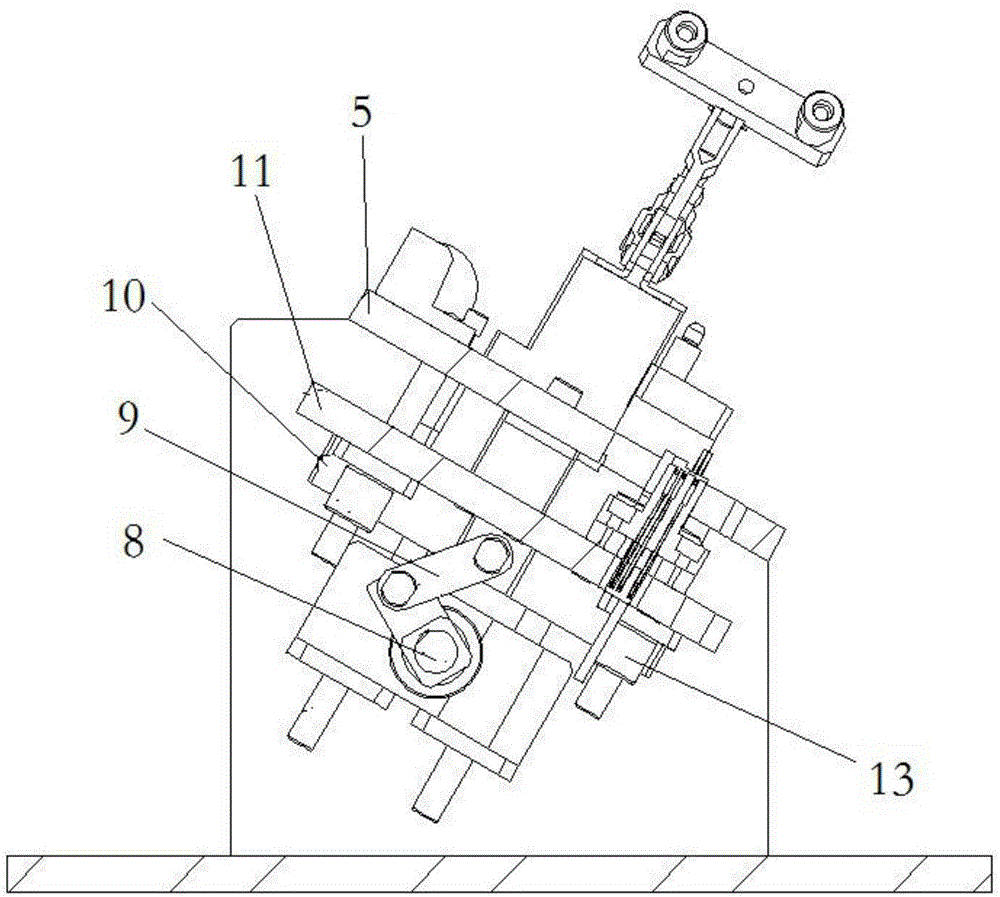

[0022] S4) Swing the pendulum 7, drive the detection terminal to be inserted into the terminal port of the product under test through the link mechanism 9 and the detection installation plate 11, and complete the test content.

Embodiment 2

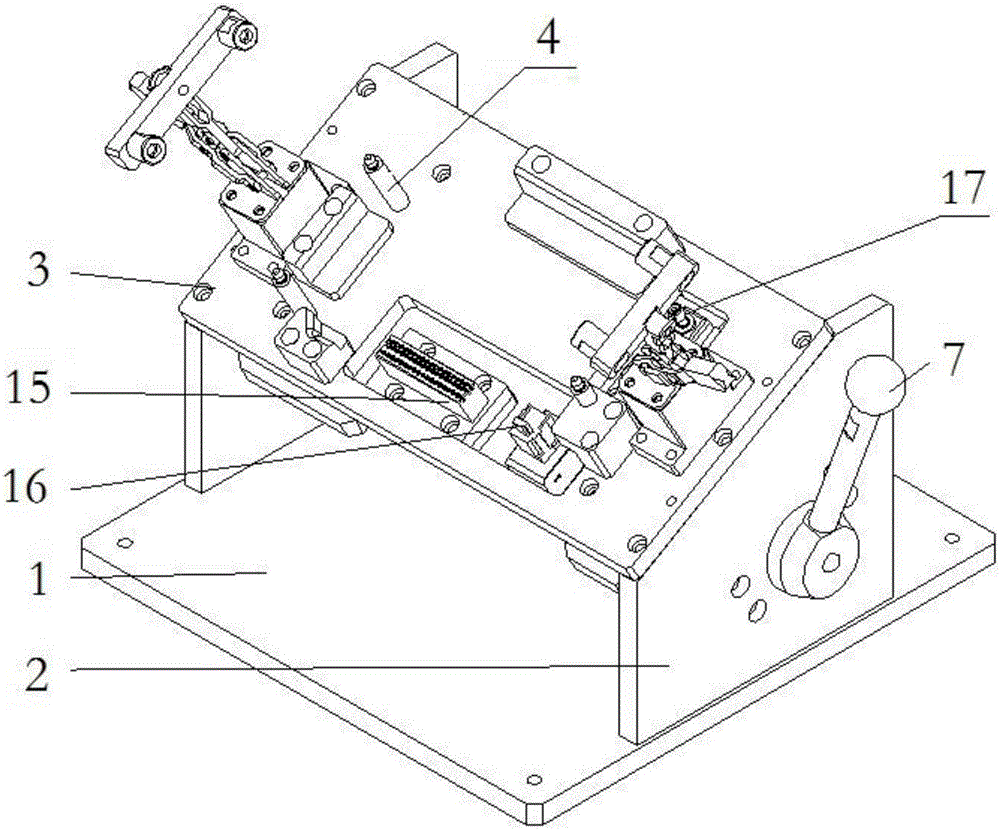

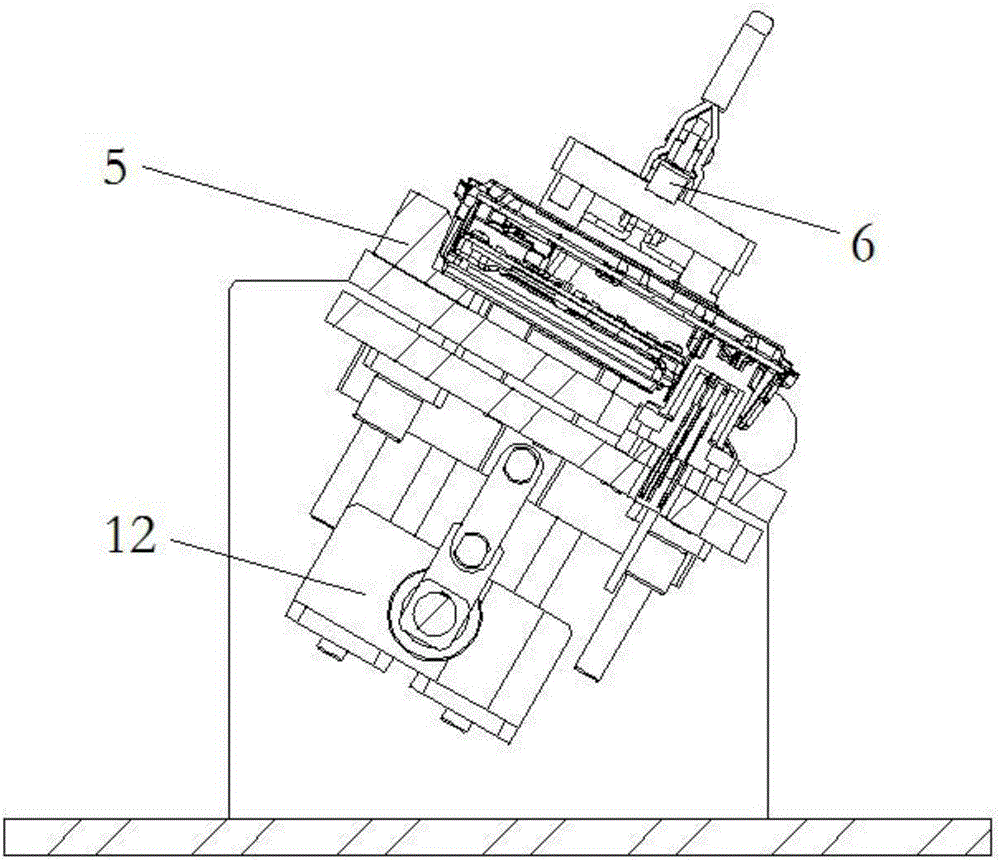

[0024] The device for implementing the detection method described in Embodiment 1 includes a bottom plate 1 , a vertical plate 2 and a top plate 3 which are fastened and connected. The product fixing device is connected on the top plate 3, and a swing rod 7 is provided on the outside of the vertical plate 2. The swing rod 7 is connected to the linkage mechanism 9 through the connecting shaft 8, and the linkage mechanism 9 is connected to the detection installation plate 11 through the connector 10, and the detection installation A linear bearing a is provided between the plate 11 and the top plate 3 to ensure that the relative position to the top plate 3 remains unchanged, and a linear bearing b13 is installed between the connecting piece 10 and the bearing fixing seat 12 to ensure that the connecting piece 10, the detection installation plate 11 and the top plate 3 are mutually In parallel, a number of detachable detection terminals are provided on the side of the upper surfac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com