Method for determining floor water inrush danger level of coal mining working faces in personalized manner

A technology of coal mining face and danger level, which is applied in the level field, can solve the problem of establishing the functional dependence of water inrush risk and influencing factors, the factors of water inrush risk are not comprehensively considered, the degree of mining pressure damage of coal seam floor is not considered, and the The water inrush hazard level evaluation is scientific and reasonable by solving problems such as the groundwater conductance height of the confined groundwater and the water-rich index of the aquifer in the lithologic combination floor of the water-retaining section.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

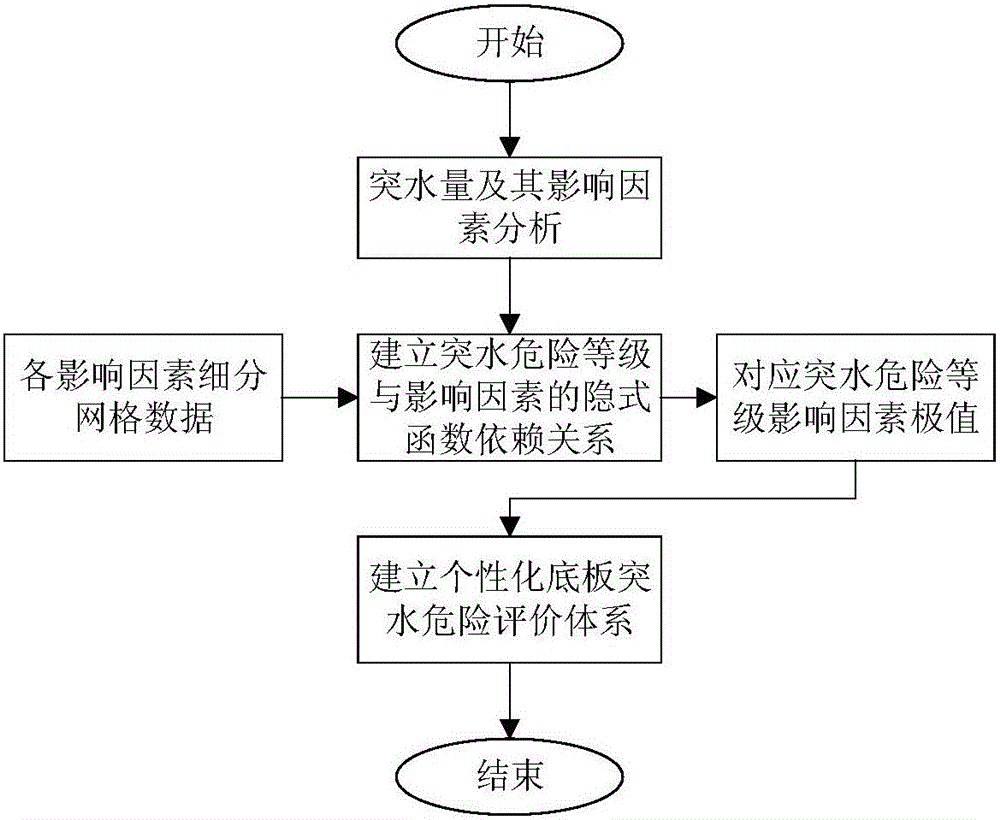

[0039] The invention provides a method for individually determining the risk level of water inrush from the floor of a coal mining face. This method comprehensively considers the factors such as the water pressure of the coal mining face floor, the thickness of the water-resisting layer, the damage phenomenon of the coal seam floor pressure, the lithology combination of the rock strata in the water-resisting section, and the development of the original conduction of groundwater under pressure on the floor, and establishes the relationship between these influencing factors and the outburst. The implicit function dependence of the water inrush hazard level is analyzed through interpolation to establish a comprehensive evaluation index system for evaluating the water inrush hazard level of the floor. This method fully considers various factors that affect the threat of water inrush from the coal mining floor, and establishes the functional dependence relationship between each infl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com