Bracket and construction method of deep trench support

A technology of deep grooves and corbels, which is applied in excavation, infrastructure engineering, construction, etc., can solve the problems of non-reusable use and inconvenient installation of corbels, and achieve the solution of non-reusable use, convenient dismantling, and avoiding construction steps Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

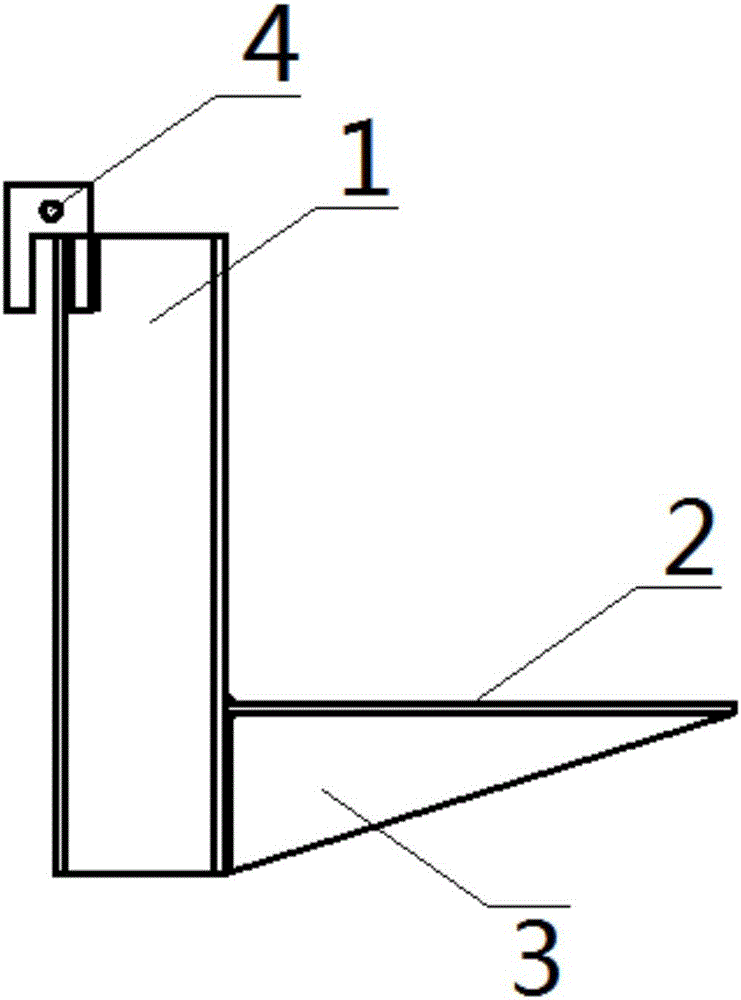

[0031] refer to Figure 1 to Figure 2 , the present embodiment provides a corbel, comprising a vertically arranged I-beam 1, a bottom plate 2, and a reinforcing rib 3, the bottom plate 2 is horizontally arranged and fixed on the lower part of the right side flange of the I-beam 1, the The reinforcing rib 3 is vertically fixed on the bottom of the bottom plate 2 and is vertically fixedly connected with the right side flange of the I-beam 1, and also includes a suspension device 4, and the suspension device 4 is fixed on the left side of the I-beam 1 upper edge.

[0032] A kind of corbel of this embodiment, since the suspension device 4 is arranged on the upper part of the left flange of the I-beam 1, when the corbel is installed, only the corbel needs to be fixed on the top of the steel sheet pile wall through the suspension device 4 , the installation of the corbel can be completed, unnecessary construction steps such as welding are avoided, and the problem of inconvenient co...

Embodiment 2

[0038] refer to Figure 1 to Figure 3 , this embodiment provides a construction method for deep trench support.

[0039] The technical scheme of the construction method of a kind of deep trench support of the present embodiment is as follows:

[0040] A construction method for deep trench support, the steps are as follows:

[0041] In the first step, several steel sheet piles 5 are driven into both sides of the deep trench to be constructed to form steel sheet pile walls on both sides of the deep trench to be constructed, and the top elevations of several steel sheet piles 5 are unified, and the top elevations of the steel sheet piles 5 are uniform Finally, the purlin 6 can be installed horizontally, which strengthens the supporting effect of the purlin 6 on the steel sheet pile wall;

[0042] In the second step, a foundation trench is excavated between the steel sheet pile walls on both sides, and the depth of the foundation trench is greater than the height of the corbel i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com