Open gear oil composition and preparation method thereof

An oil composition and open gear technology, applied in the field of lubricating oil, can solve the problems of complex structure of synthetic ester oil, inability to scale up production, complicated preparation, etc., and achieve excellent low temperature fluidity, high temperature adhesion, and high bearing capacity , the effect of a wide range of applications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

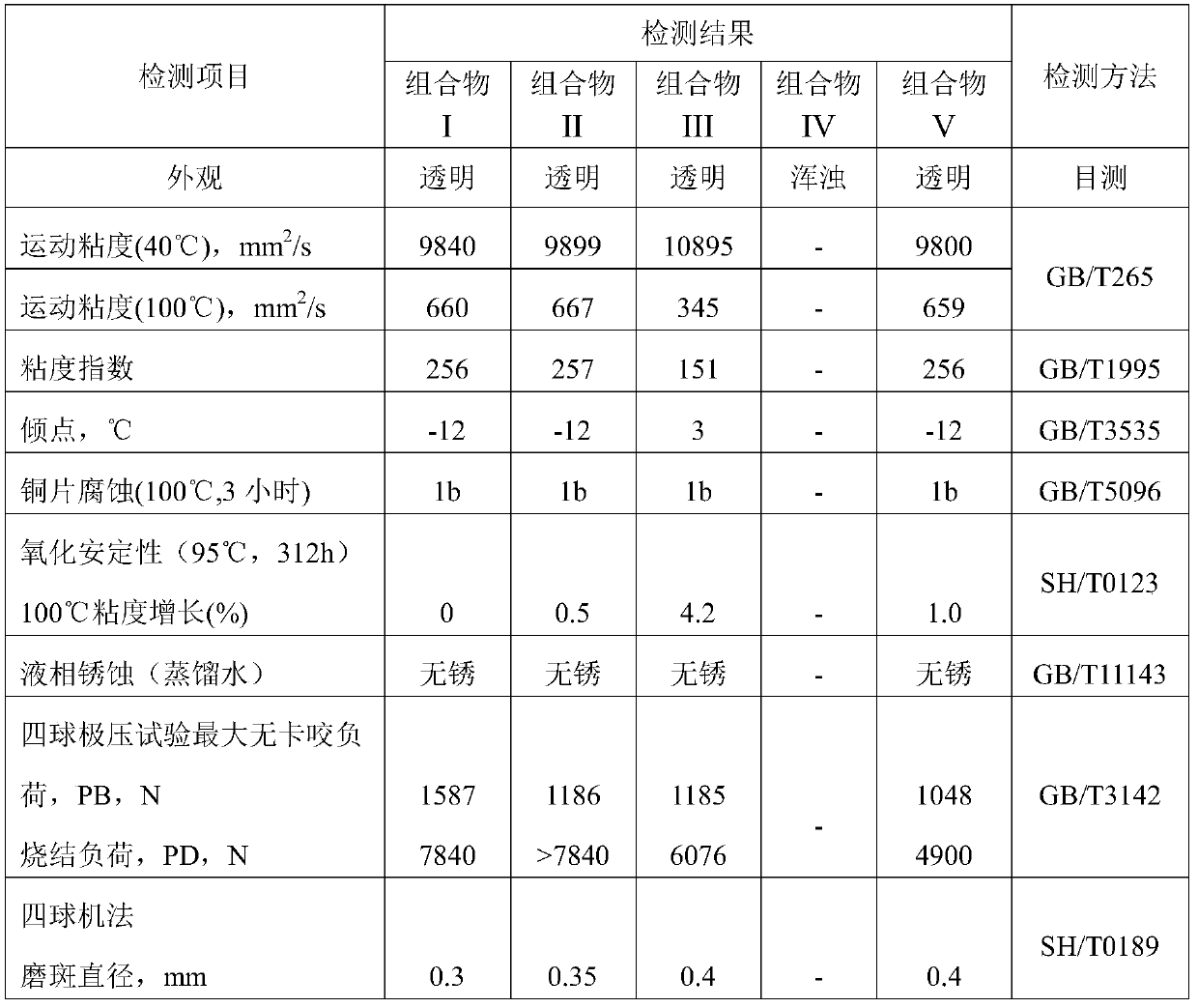

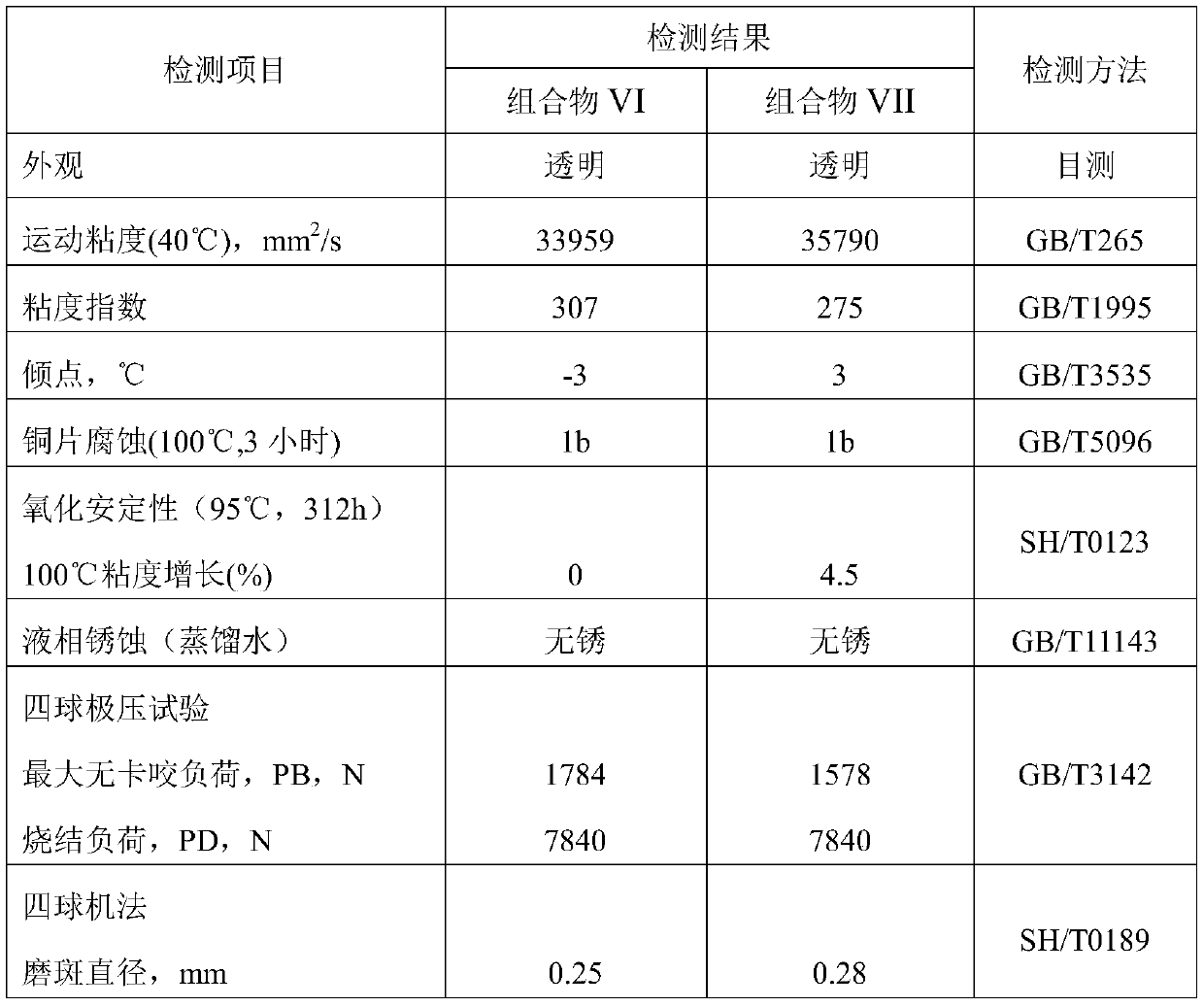

Examples

preparation example Construction

[0051] The present invention also provides a method for preparing the open gear oil composition according to the present invention, which includes: mixing the components of the open gear oil composition.

[0052] Specifically, according to the method of the present invention, comprise the following steps:

[0053] Add ester synthetic oil into the reactor, keep the temperature at 75-90°C, then add oil-based antiwear agent, stir until uniform and transparent, stop heating and lower the temperature to 40-60°C, then add extreme pressure antiwear agent , an antioxidant, and a metal passivator are added into a reactor, and stirred until uniform and transparent to obtain an open gear oil composition.

Embodiment 1

[0057] With 94.4 parts by weight of ester synthetic oil (manufacturer: Italmatch Chemicals, brand: Ketjenlube2700, this ester synthetic oil is formed by copolymerization of fourteen alpha olefin, sixteen alpha olefin, and the reaction product of maleic anhydride and ethanol, Its average weight-average molecular weight is 7000Da, CAS number: 173521-40-9) into the reaction kettle, keep the temperature of the kettle at 80°C; add 1 part by weight of dodecyl hydroxystearic acid, stir until uniform and transparent, stop heating and use Cooling water reduces the still temperature to 50°C; then 2 parts by weight of isobutylene sulfide (manufacturer: Boda Chemical Co., Ltd., trade mark: T321, the same below), 1.5 parts by weight of tricresyl phosphate (manufacturer: Bo Da Chemical Co., Ltd., brand: T306, the same below), 1 weight part of octylbutyl diphenylamine, 0.1 weight part of benzotriazole derivatives (manufacturer: Jinzhou Kangtai Lubricating Oil Additive Co., Ltd., brand: T551, ...

Embodiment 2

[0059] The open gear oil composition II was prepared according to the same method as in Example 1, except that 1.5 parts by weight of tricresyl phosphate in Example 1 was replaced by 1.5 parts by weight of isobutylene sulfur.

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of polymerization | aaaaa | aaaaa |

| viscosity index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com