Fully-automatic straightening device for workpiece notch

A fully automatic, workpiece slot technology, applied in transportation and packaging, conveyor objects, etc., can solve problems such as low production efficiency, increased labor costs, and inability to fully automate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

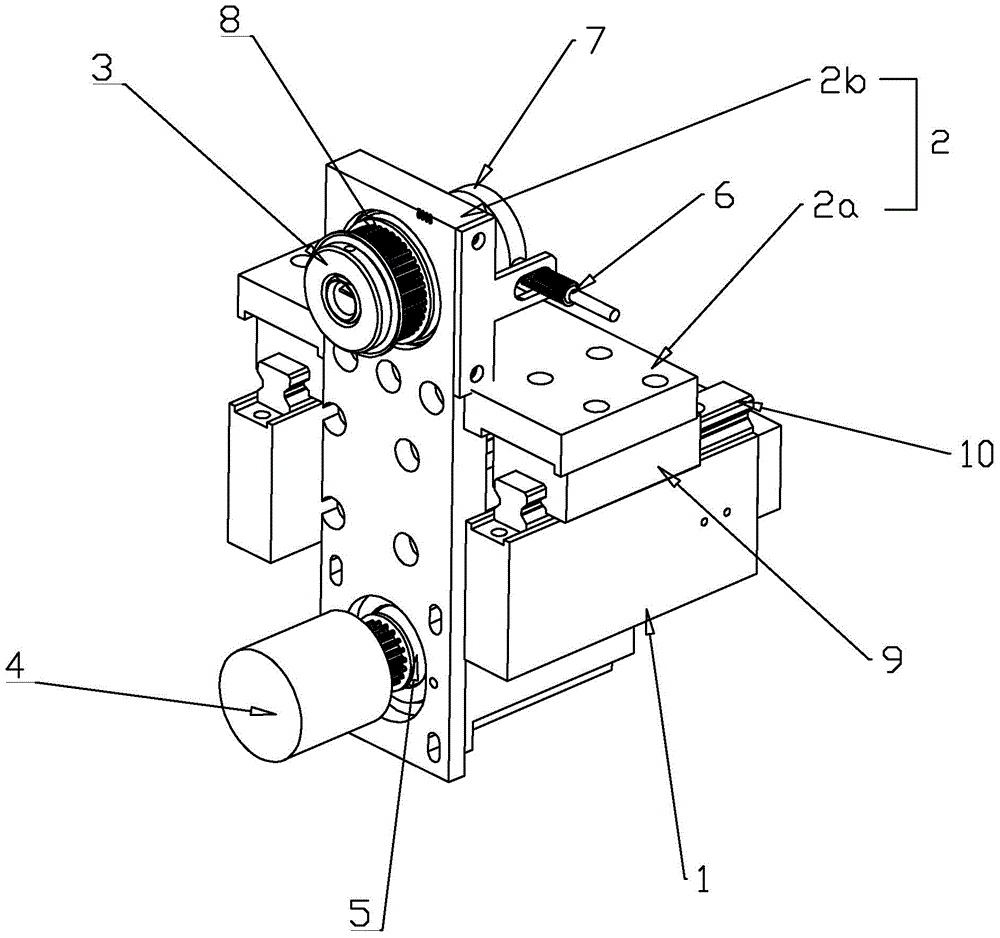

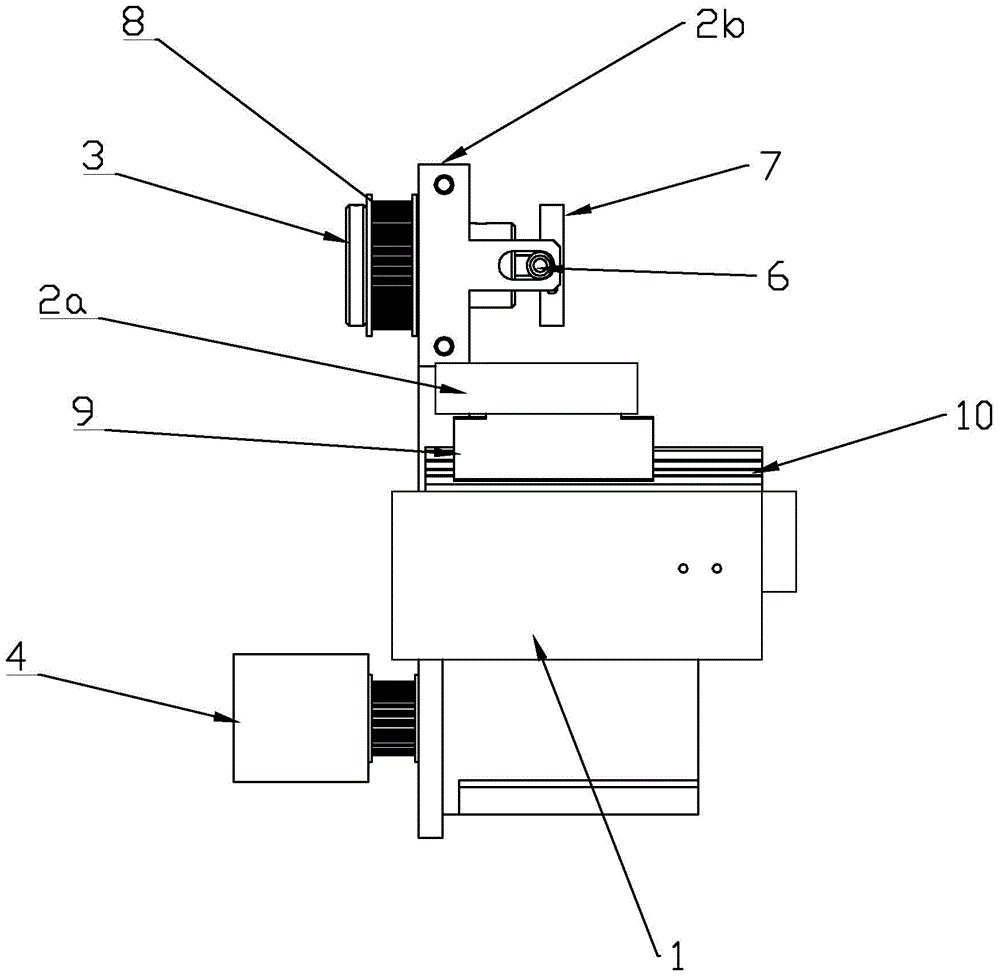

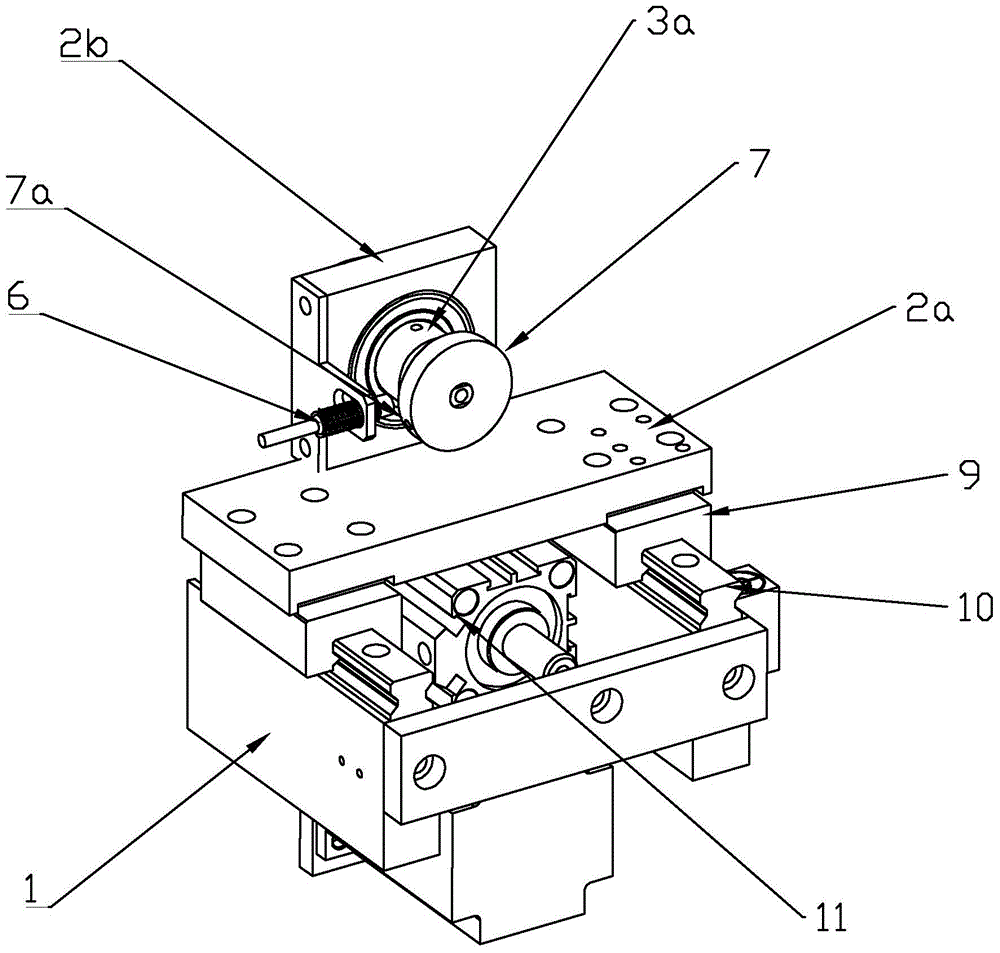

[0030] A fully automatic straightening device for a workpiece notch, comprising a controller (not shown in the figure), a frame 1, a mounting frame 2 is slidingly connected to the frame 1, and the mounting frame 2 is connected to a sliding driving member 11; The frame 2 is provided with a head recognition device 3 for rotating and clamping into the workpiece slot; the head recognition device 3 is connected to the rotary drive part 5 with an encoder 4, and the encoder 4 is used to detect the rotation angle of the rotary drive part 5; The device 3 is provided with an induction coil 7, and the induction coil 7 rotates together with the head recognition device 3. The induction coil 7 is provided with an induction part 7a, and the induction part 7a can be a structure such as a groove 3b2 or a bump, as long as the first approaching It is enough that the switch 6 can identify the distance sensing; the first proximity switch 6 that cooperates with the induction coil 7 is provided on th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com