Driving system of main cylinder of heavy-duty double-function hydraulic press and its application method

A driving system and dual-function technology, applied to the driving device of forging presses, etc., can solve the problem of single function of heavy hydraulic presses

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The specific embodiments of the present invention will be described in further detail below in conjunction with the drawings and embodiments. The following examples are used to illustrate the present invention, but not to limit the scope of the present invention.

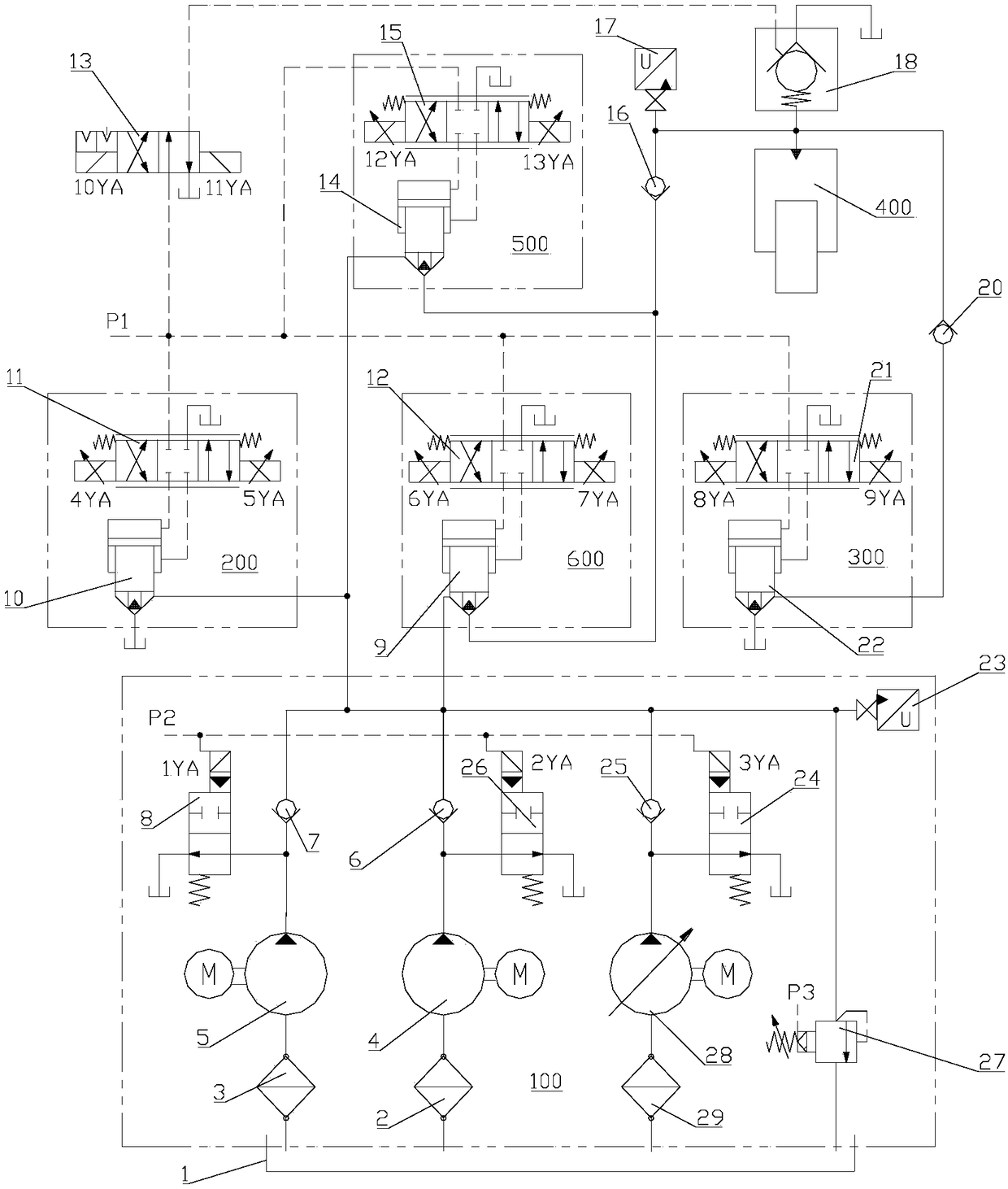

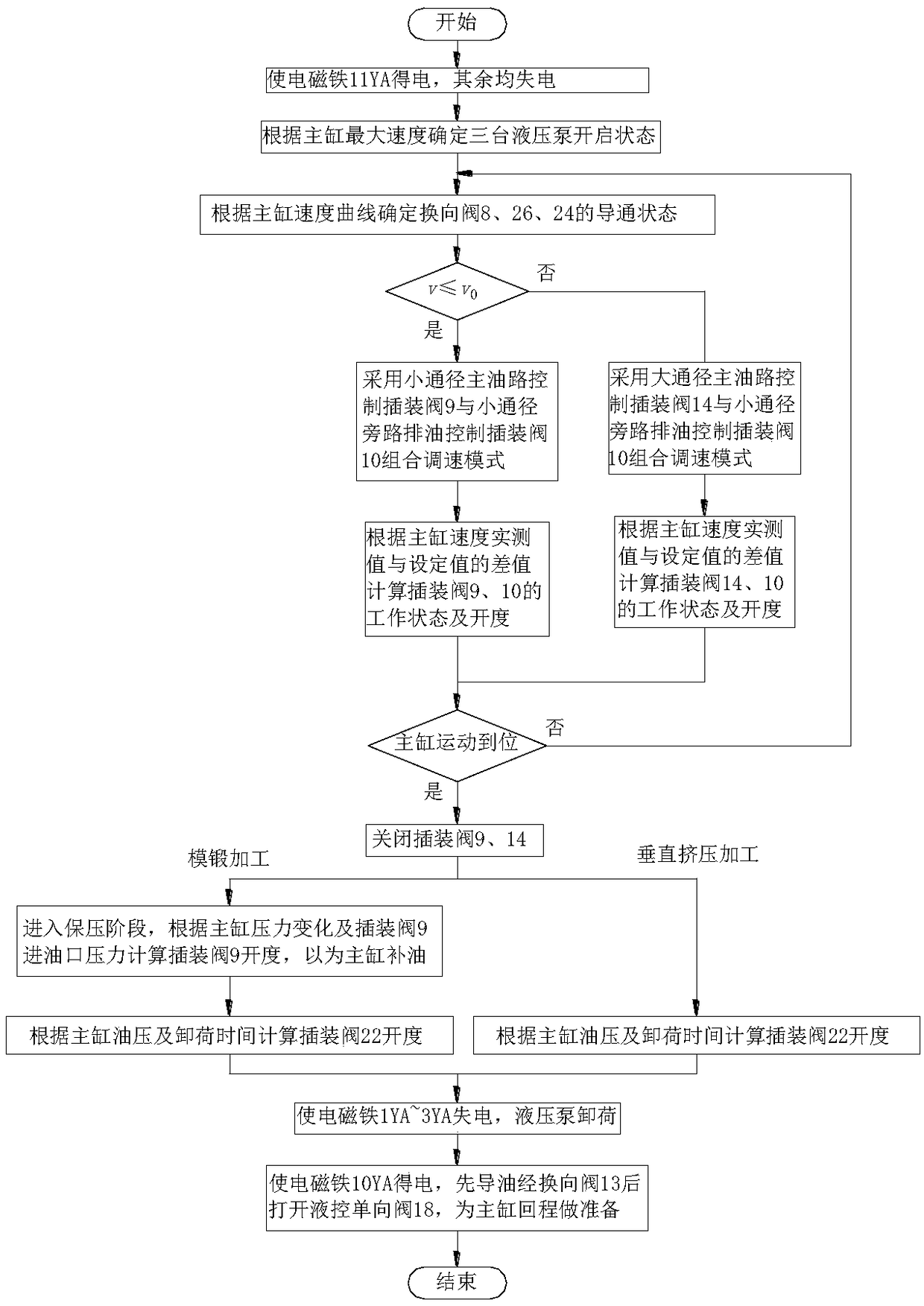

[0036] See figure 1 As shown, the present invention provides a main cylinder driving system of a heavy-duty dual-function hydraulic machine, including: an oil tank 1, an oil supply circuit 100 connected with the oil tank 1, a bypass oil discharge circuit 200, an unloading circuit 300, and a plunger cylinder 400.

[0037] The oil supply circuit 100 includes three parallel high-flow oil supply pumps 5, small-flow oil supply pumps 4, and variable oil supply pumps 28, and the large-flow oil supply pump 5, low-flow oil supply pump 4, and variable oil supply pump 28 each pass through an oil filter 2. , 3, 29 are connected to the fuel tank 1, and the other end is respectively connected with a one-way control valve 7, 6,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com