Rotary type high-accuracy automatic sorting device for internal thread detection of small-sized revolved body workpiece and automatic sorting method adopting device

A technology for detecting automatic and sorting devices, which is applied in the field of robots, and can solve problems such as unqualified processing threads, impact on equipment performance, and personal safety of equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

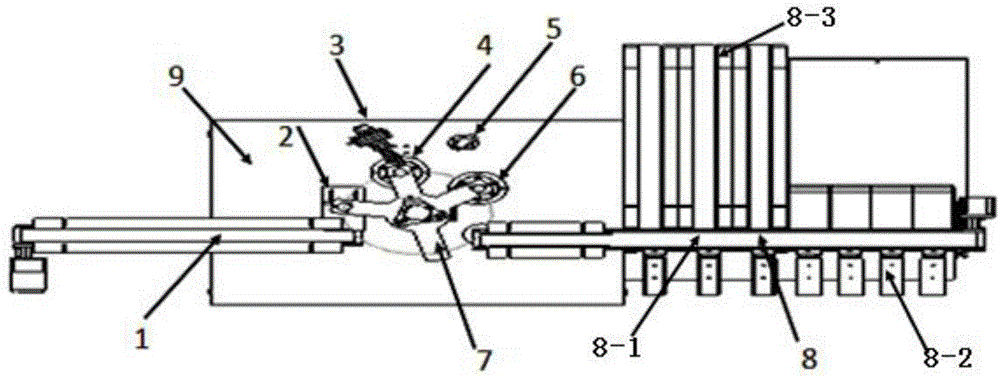

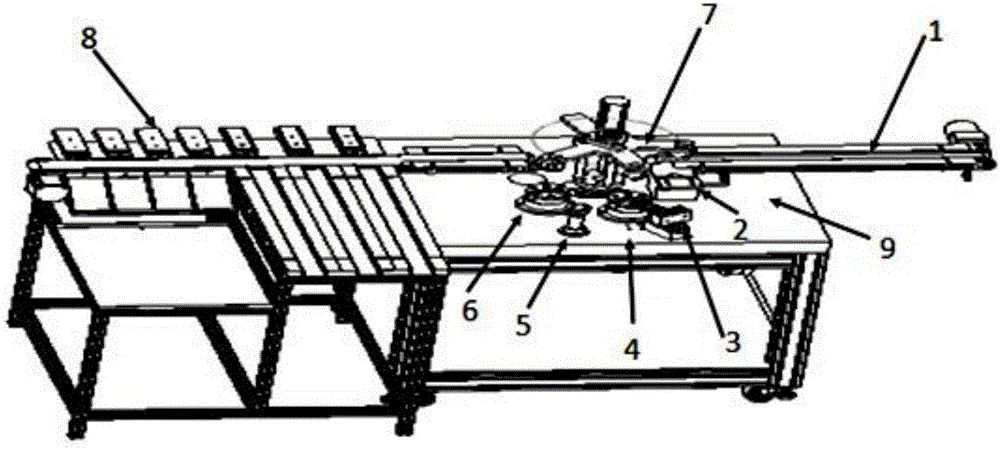

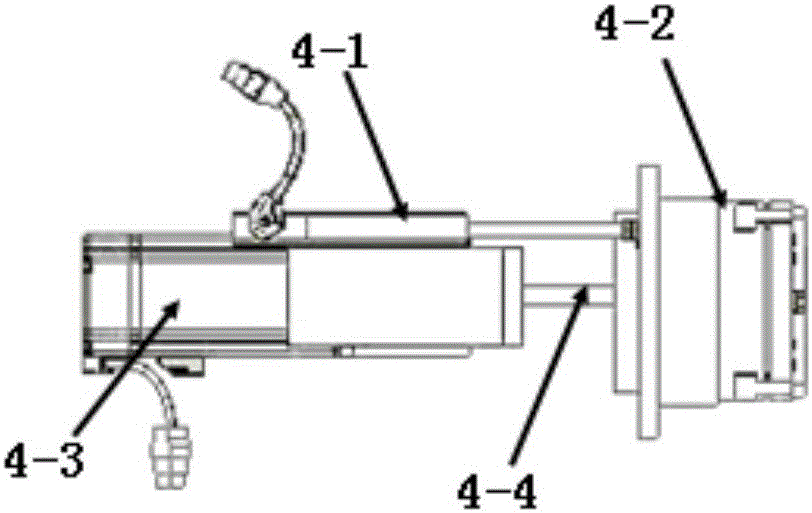

[0024] Such as Figure 1-2 As shown, the rotary high-precision internal thread detection automatic sorting device for small rotary workpieces according to the present invention includes: a feeding channel 1, a first visual detection station 2, a turning mechanism 3, and a thread through-gauge detection mechanism 4 , The second visual detection mechanism 5, the thread stop gauge detection mechanism 6, the high-precision rotary index plate 7, the blanking mechanism 8 and the base 9.

[0025] The base 9 is a frame structure, and the above-mentioned material channel 1, the first visual inspection station 2, the turning mechanism 3, the thread through gauge detection mechanism 4, the second visual inspection mechanism 5, and the thread stop gauge detection mechanism are set on the base 9 6. High-precision rotating index plate 7, feeding mechanism 8.

[0026] Further, the above-mentioned feeding channel 1, the first visual detection station 2, the turning mechanism 3, the thread th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com