Heat-mass co-transfer evaporation and crystallization system and working method thereof

A technology of evaporative crystallization and heat quality, applied in the direction of evaporative separation crystallization, evaporation, separation methods, etc., can solve the problems of high energy consumption, large consumption of precious metals, high heating temperature, etc., and achieve low energy consumption and small consumption of precious metals , the effect of less energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

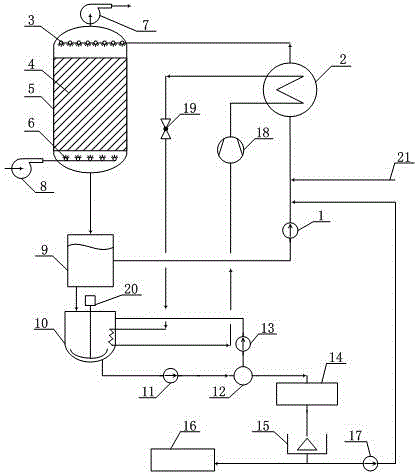

[0013] figure 1 It is the heat and mass co-transfer evaporation crystallization system proposed by the present invention, refer to below figure 1 Describe the working process of the system.

[0014] The air flows in from the lower air inlet of the heat and mass transfer tank 5 through the blower 8, and after heat and mass transfer occurs with the low-concentration solution sprayed from top to bottom, it passes through the induced draft fan 7 from the upper air outlet of the heat and mass transfer tank 5 into the environment;

[0015] The initial solution flows into the system from the material inlet 21, and mixes with the clear mother liquor at the outlet of the mother liquor circulating pump 1 and the mother liquor at the outlet of the mother liquor pump 17 to form a low-concentration solution. The low-concentration solution flows into the cold side of the heater 2 and absorbs its low boiling point on the hot side After the heat released by the working fluid, it flows in fr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com