System for harvesting high-stalk crops

A technology of crops and transmission rods, applied in the field of agricultural tools, can solve the problems of high labor intensity, poor cutting degree, and sickle injury, etc., and achieve the effect of low labor intensity, safe use and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention will be further elaborated below in conjunction with the accompanying drawings.

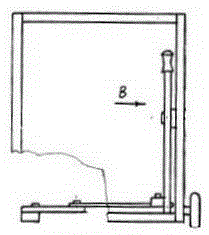

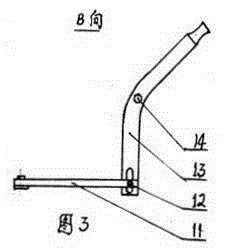

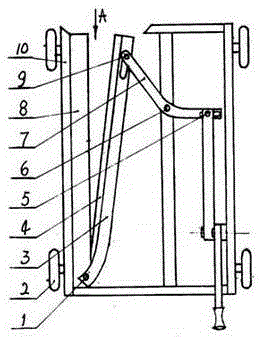

[0011] figure 1 , figure 2 , image 3 It is a system for harvesting tall stem crops. Four small wheels (2) use the wheels that general child's car is used, are installed in the bottom of casing (10) both sides. Cutting bottom plate (8) is made of medium carbon steel, is fixed on the casing (10). The blade is made of tool steel, fixed on the blade rod (3), the pin shaft (1) of the blade rod (3) is connected to form a 120° elbow, and the blade rod (3) is connected to the cutting base plate with the pin shaft (1) (8) Connection. Blade rod (3), drive rod (7), drive rod (11) and handle (13) are respectively connected with bearing pin (9), (6), (5), (12) (14) to form drive mechanism. And at the pin shaft (9) coupling end of blade rod (3), the pin shaft (5) coupling end of transmission rod (7), the pin shaft (12) coupling end of handle (13) open a track-shaped small g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com