Air-cooled electric vehicle controller

An electric vehicle controller and air-cooling technology, applied in electrical components, electrical equipment structural parts, cooling/ventilation/heating transformation, etc., can solve the loss of controller function, power tube burnout failure, power burnout failure, etc. problems, to achieve the effect of eliminating overheating burnout, ensuring timeliness and effectiveness, and eliminating the hidden danger of overheating burnout

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

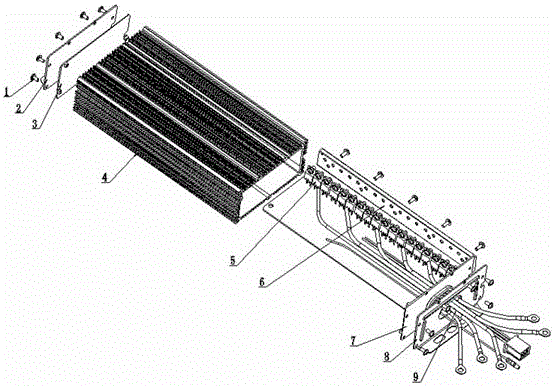

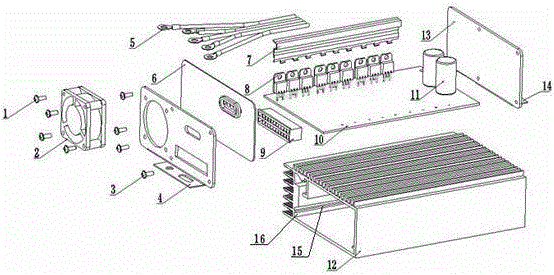

[0015] Such as image 3 , Figure 4 As shown: the present invention includes screw 1, turbo fan 2, self-tapping screw 3, front baffle 4, wire 5, front gasket 6, spring leaf 7, power tube 8, functional plug 9, PCB board 10, capacitor 11, Hollow shell 12 , rear gasket 13 , and rear baffle 14 . The outer surface of the hollow shell is distributed with strip-shaped heat dissipation teeth, and two rows of bumps are added on each heat dissipation tooth. The bottom of the hollow shell 12 is square, and a heat dissipation boss is arranged on the middle side of the hollow shell 12. 16. On the heat dissipation boss 16, there are ribs 15 for installing the spring sheet. There are four small holes on the front baffle 4 and the rear baffle 14 respectively. The spring sheet 7 has eighteen feet, and each foot corresponds to One power tube presses the power tube 8 on the boss 16 of the hollow shell, and the eighteen power tubes welded on the circuit board are directly attached to the boss 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com