Crimping tool structure of electric reactor coil terminal

A terminal crimping and reactor technology, applied in coil manufacturing, circuit/collector parts, circuits, etc., can solve the problems of high current, low production efficiency, rework, etc., to achieve accurate and uniform size, firm and reliable crimping, The effect of high work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

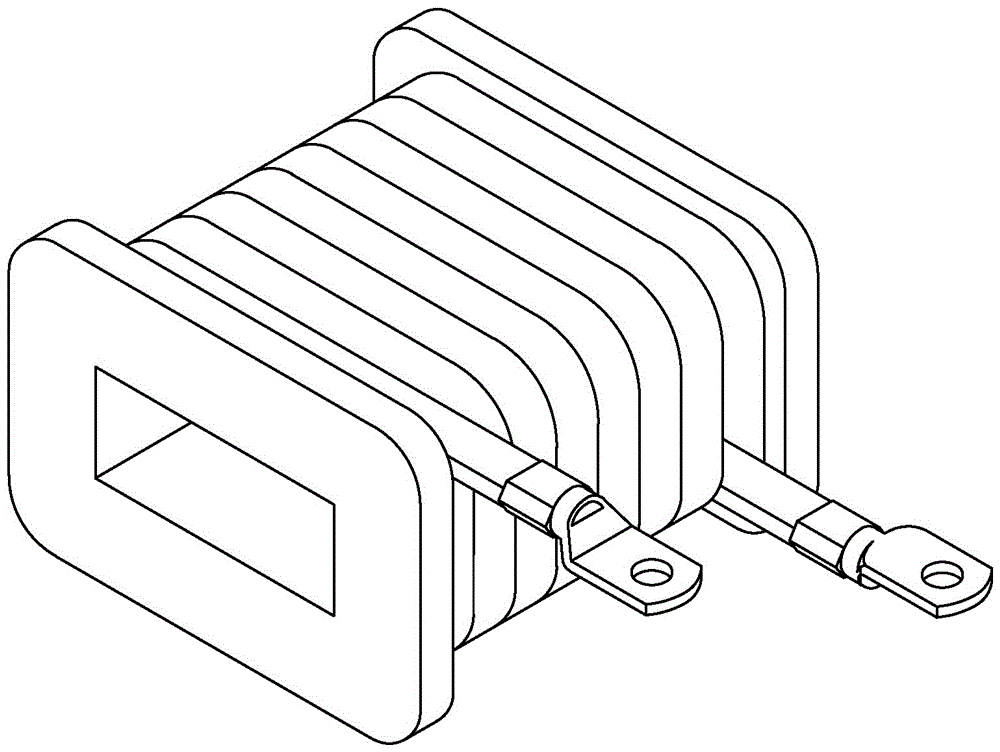

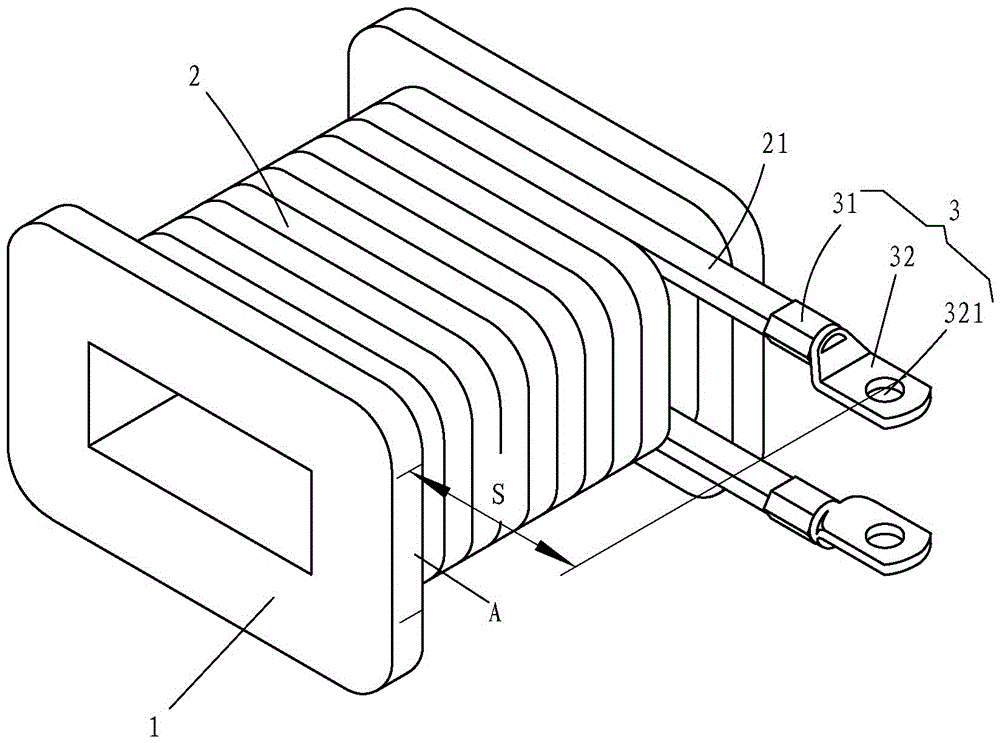

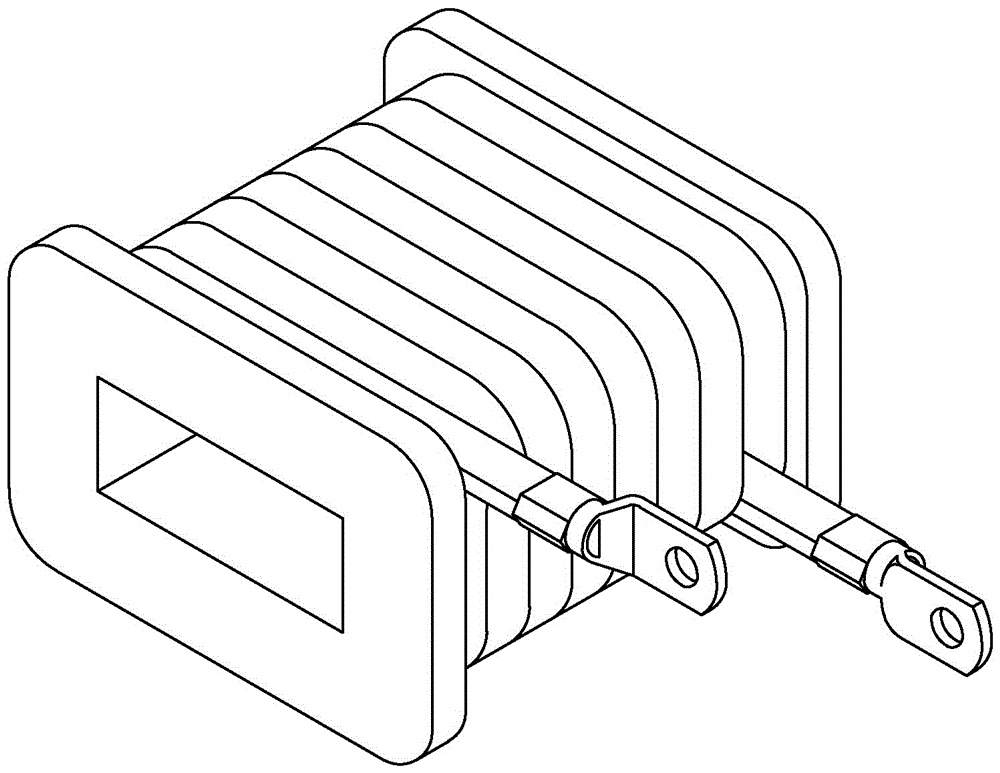

[0035] See Figure 1 and figure 2 As shown, the reactor coil includes a skeleton 1, a coil 2 and a terminal 3, the terminal 3 includes a crimping end 31 and a connecting end 32, the crimping end 31 has an inner hole D, and the connecting end 32 There is a bolt hole 321 on it;

[0036] see again Figure 2-3 with Figure 4 , a reactor coil terminal crimping tooling structure, including a pneumatic press (not shown), a skeleton 1, a coil 2, a terminal 3, an upper tooling body 4, a lower tooling body 5, an upper die 6, a lower tooling body Die 7, a positioning unit 8; the pneumatic press has a piston rod 12; the upper tooling body 4 includes a column 41 and a guide post 42, the upper end of the column 41 is recessed downward to form a The piston rod 12 matches the counterbore 411, and the piston rod 12 is inserted in the counterbore 411; the bottom of the column 41 extends vertically backward with a mounting plate 43, and the top of the guide column 42 is vertically fixed on th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com