Cement-based composite material reinforced concrete interface shearing test device and test method

A composite material and shear test technology, applied in the field of cement-based composite material reinforced concrete interface shear test device, can solve the problem that the shear strength of the interface between the reinforcement layer and the old concrete cannot be accurately measured, and the bond failure form of the reinforcement layer is not directly considered. Problems such as interface bonding performance, which have not yet been reported

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

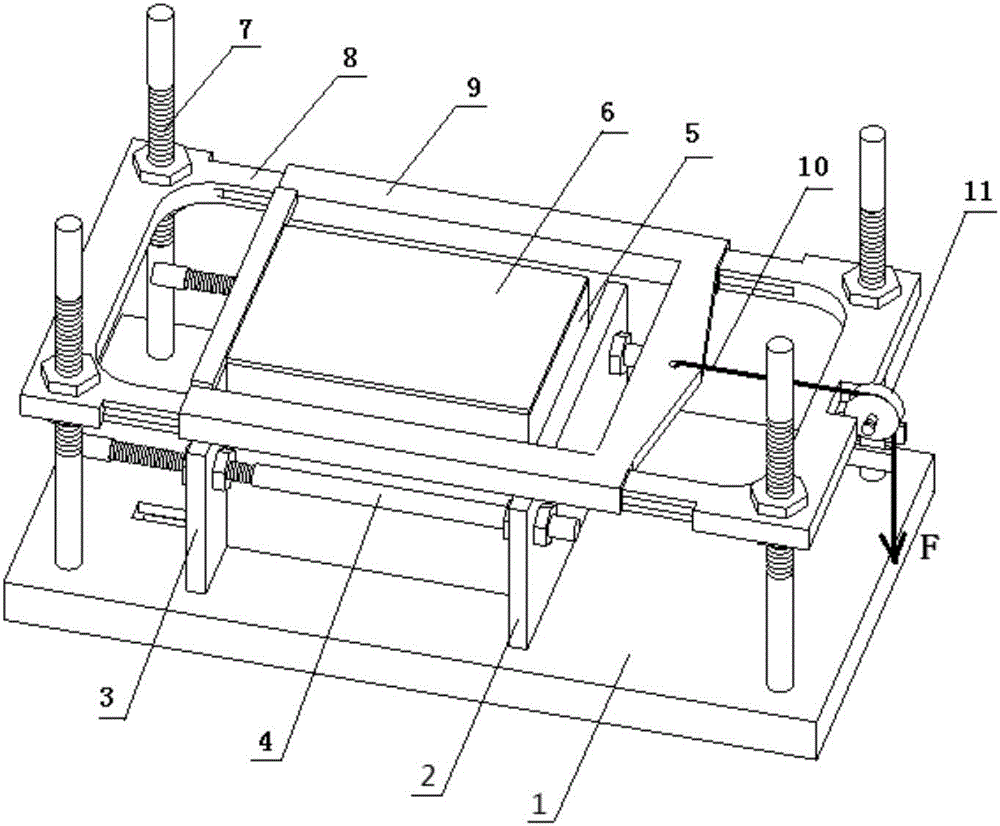

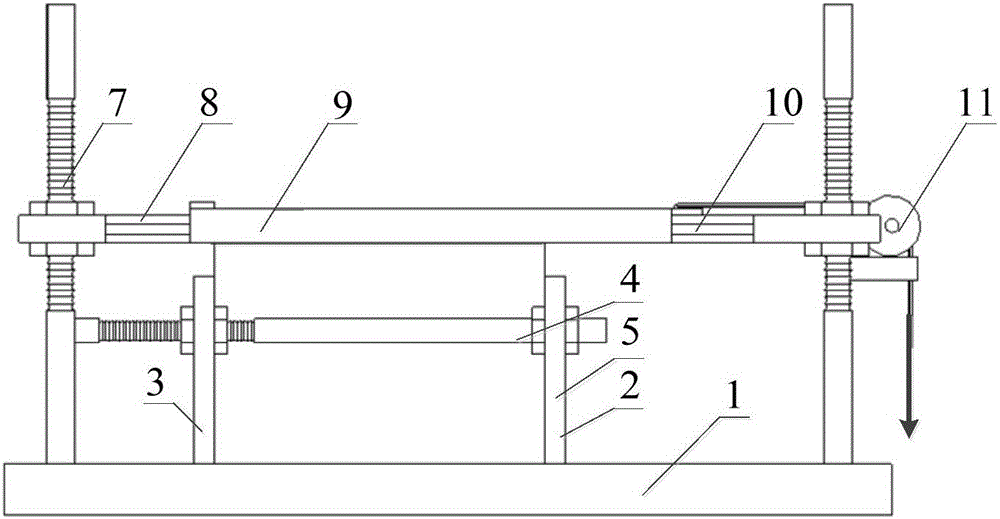

[0034] The technical solutions in the present invention will be clearly and completely described below in conjunction with the accompanying drawings in the embodiments of the present invention. The following examples are only used to illustrate the technical solutions of the present invention more clearly, but not to limit the protection scope of the present invention.

[0035] It should be noted that, in order to keep the drawings concise, each drawing only schematically shows the parts related to the present invention, and they do not represent the actual structure of the product. The "front" and "rear" of the movable front baffle and the positioning rear baffle in this article do not limit the orientation of the baffle, and can also be correspondingly expressed as the movable rear baffle and the positioning front baffle; that is, the " "Front" and "rear" are only used to distinguish two different baffles, and do not constitute a limitation on the baffles.

[0036] A cement-b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com