Automatic grading measurement method of diamond color

An automatic measurement and color grading technology, applied in the direction of color measurement devices, etc., can solve the problems of grading result differences, repeatability, and reproducibility that cannot meet the measurement results, so as to reduce the impact, ensure the signal-to-noise ratio and dynamic range, Effect of reducing measurement system error

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

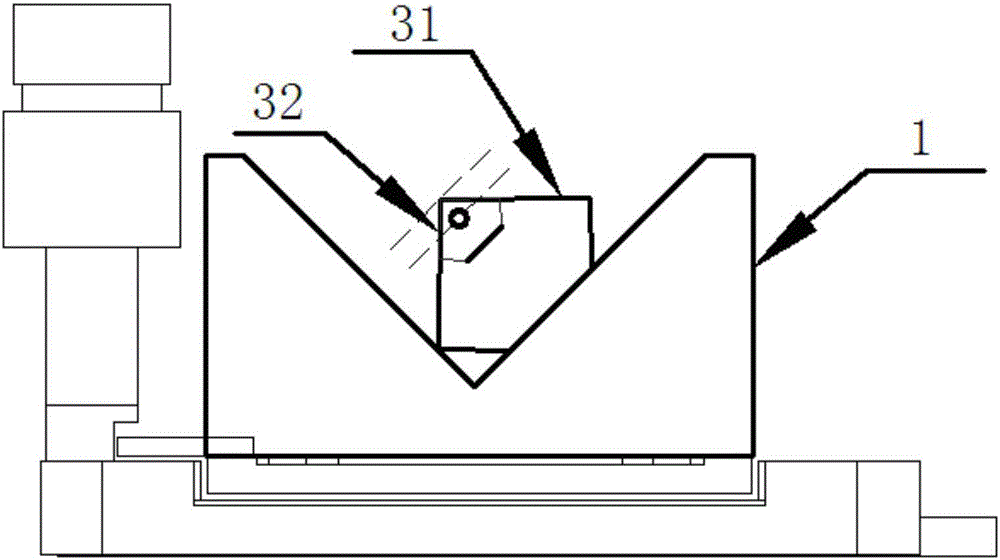

Image

Examples

Embodiment Construction

[0039] The embodiments of the present invention are described in detail below. This embodiment is implemented on the premise of the technical solution of the present invention, and detailed implementation methods and specific operating procedures are provided, but the protection scope of the present invention is not limited to the following implementation example.

[0040] An automatic measurement method for diamond color grading, comprising the following steps:

[0041] (1) Adjust the lighting and observation conditions so that the test environment is consistent with the human eye observation environment;

[0042] The lighting and observation conditions are as follows: conform to the lighting conditions of the CIE standard lighting body D65, use a white diffuse reflection background, specify the observation angle of the diamond sample surface, meet the observation conditions that the line of sight is perpendicular to the pavilion when the human eye observes, and the measured ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com