High-speed high-precision non-contact type coordinate measuring machine and measuring method thereof

A three-coordinate measuring machine and non-contact technology, which is applied in the field of precision measurement, can solve problems such as low measurement speed, achieve the effect of improving measurement accuracy, improving accuracy, and meeting the needs of measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] Below by embodiment the content of the present invention is specified:

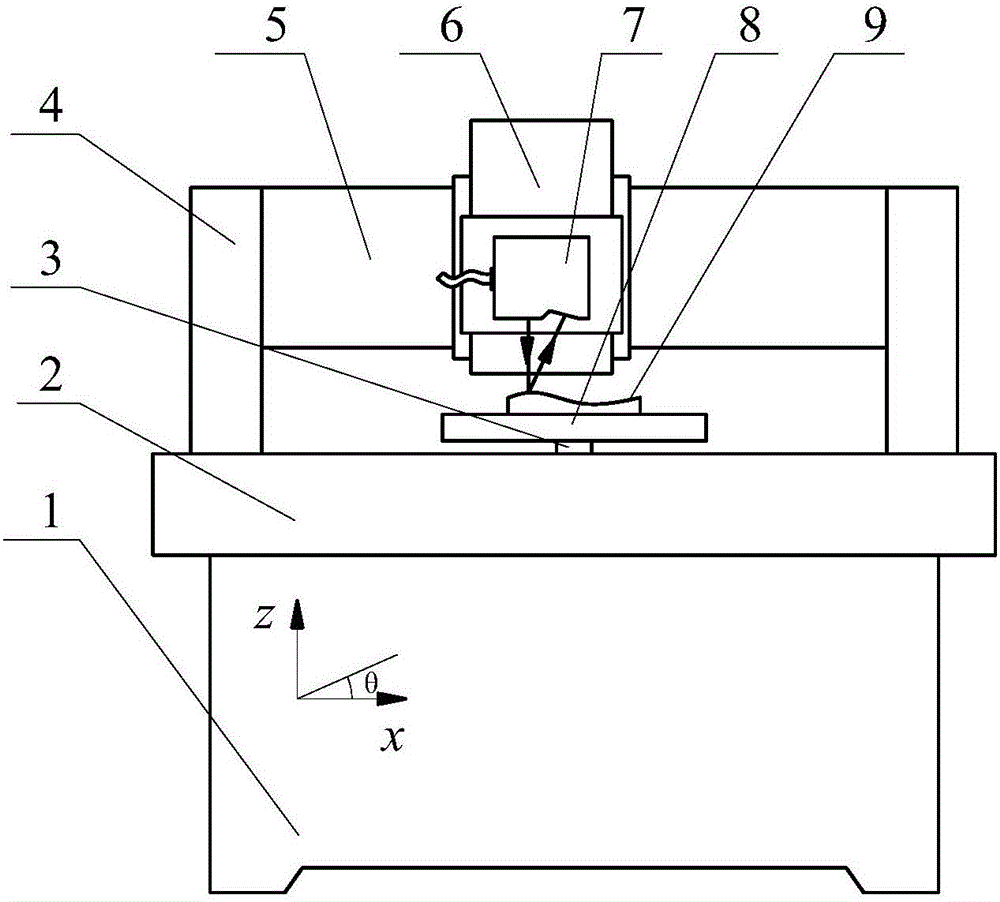

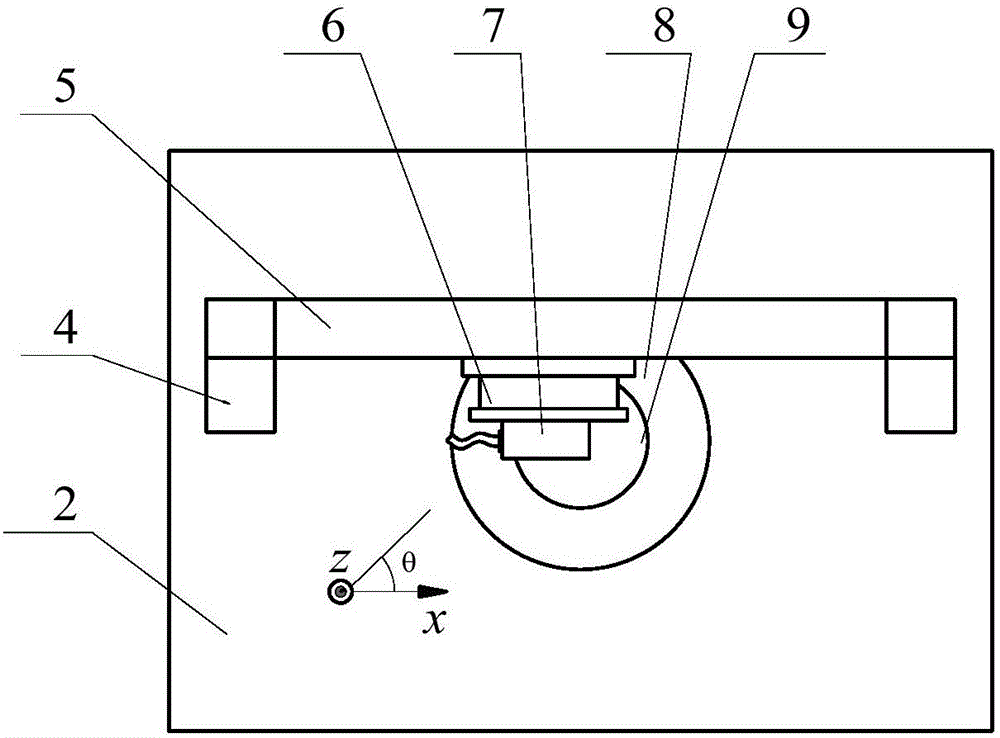

[0045] Please check figure 1 and figure 2 , a high-speed and high-precision non-contact three-coordinate measuring machine, including:

[0046] The machine tool 1 is made of natural marble, has small thermal deformation, and can ensure the measurement accuracy of the measuring machine;

[0047] The workbench 2 is mounted on the machine tool 1;

[0048] The main shaft 3 is installed vertically on the machine tool 1 and its shaft head passes through the workbench 2 upwards;

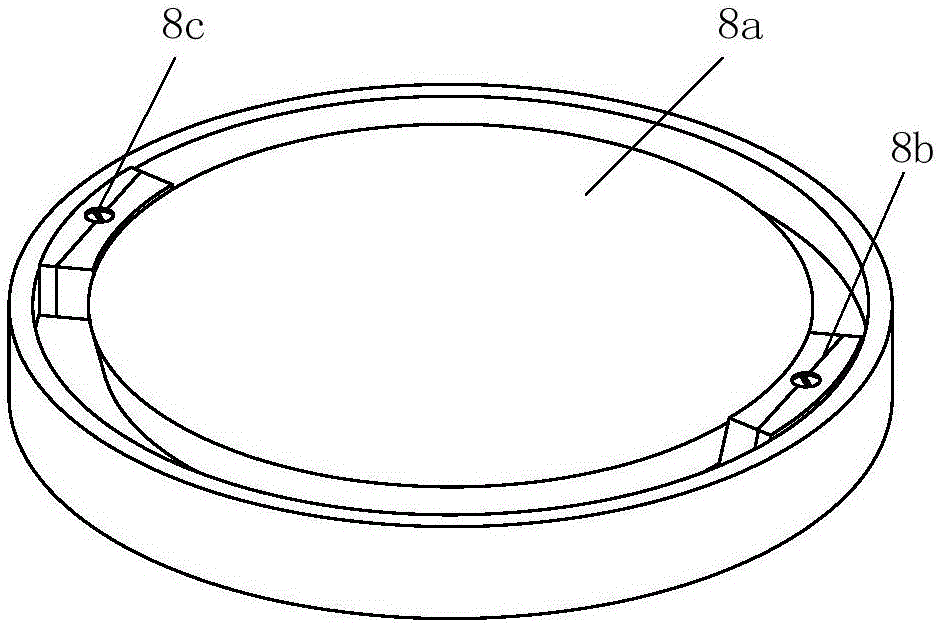

[0049] The object stage 8 is arranged on the workbench 2 and is mounted on the shaft head of the main shaft 3. The object stage 8 can be rotated by the main shaft 3 and the axes of rotation of the two coincide; the object stage 8 includes a disc-shaped object stage The main body 8a is provided with an annular chute on the main body 8a of the object stage, and two balance weights 8b are slidably mounted in the annular chute;...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com