PTFE heat exchanger

A technology of heat exchangers and heat exchange tubes, which is applied to the types of heat exchangers, heat exchanger shells, indirect heat exchangers, etc., can solve problems such as easy failure, plate corrosion, and heavy steel structures, and achieve a wide range of applications Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

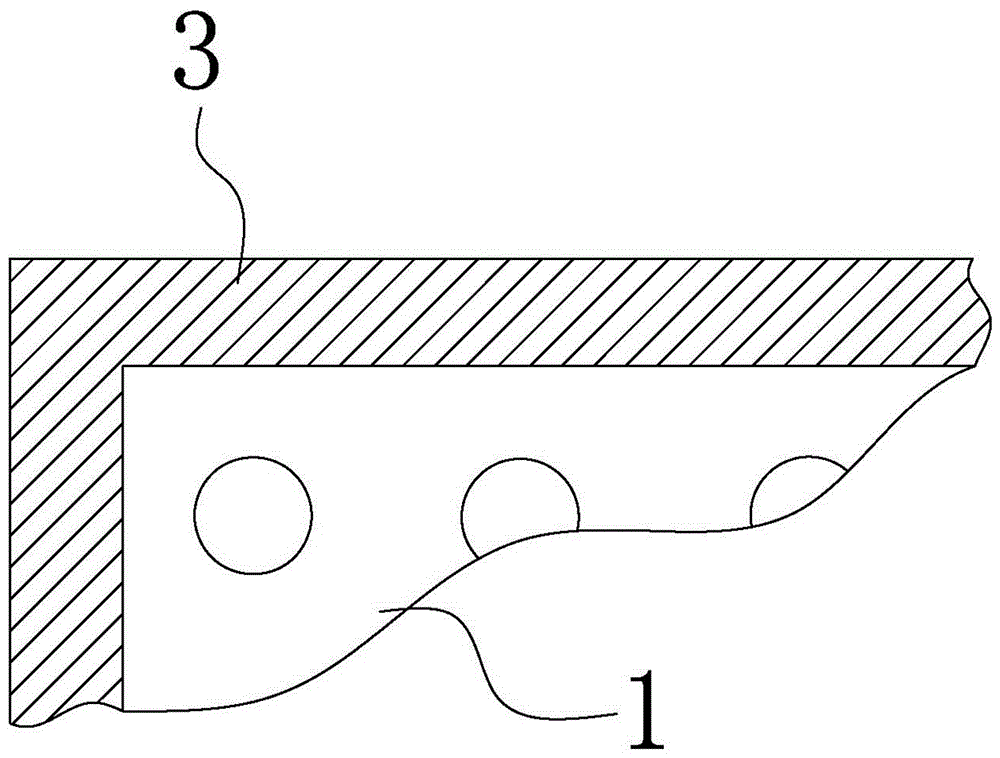

[0037] Example 1: Reference Figure 1~Figure 3 , a PTFE tubular heat exchanger, including a tube sheet 1 made of polytetrafluoroethylene material, a plurality of tube holes are opened on the tube sheet 1, and a polytetrafluoroethylene material is arranged in the tube hole The heat exchange tube 2; the error of the inner diameter, outer diameter, and wall thickness between the heat exchange tubes 1 is less than plus or minus 0.1 mm, and the wall thickness is 1 mm.

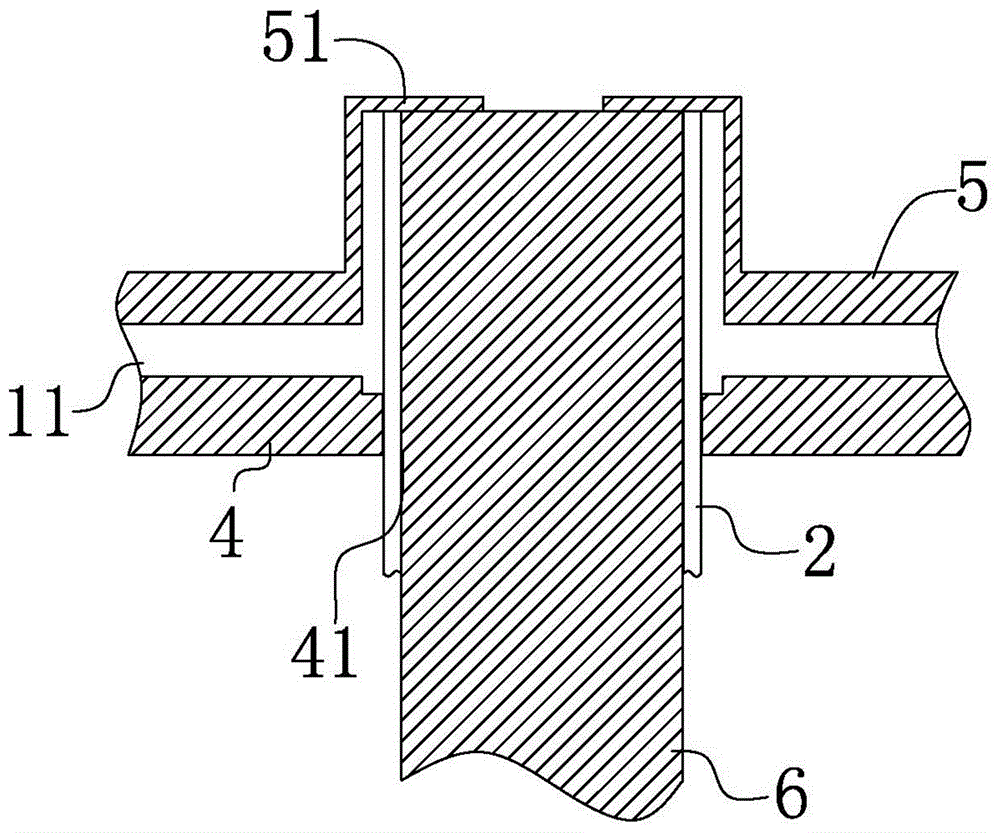

[0038] The heat exchange tube 2 and the tube sheet 1 are welded together by PFA material and auxiliary tools;

[0039] The auxiliary tools include: a frame-shaped tube sheet expansion limiting mold 3;

[0040] A tube plate supporting tray 4, on which are provided with a plurality of position-limiting holes 41 corresponding to the tube holes;

[0041] A plurality of tube sheet expansion limiting rings 5, the tube sheet expansion limiting rings 5 are provided with heat exchange tube retaining rings 51;

[0042] A...

Embodiment 2

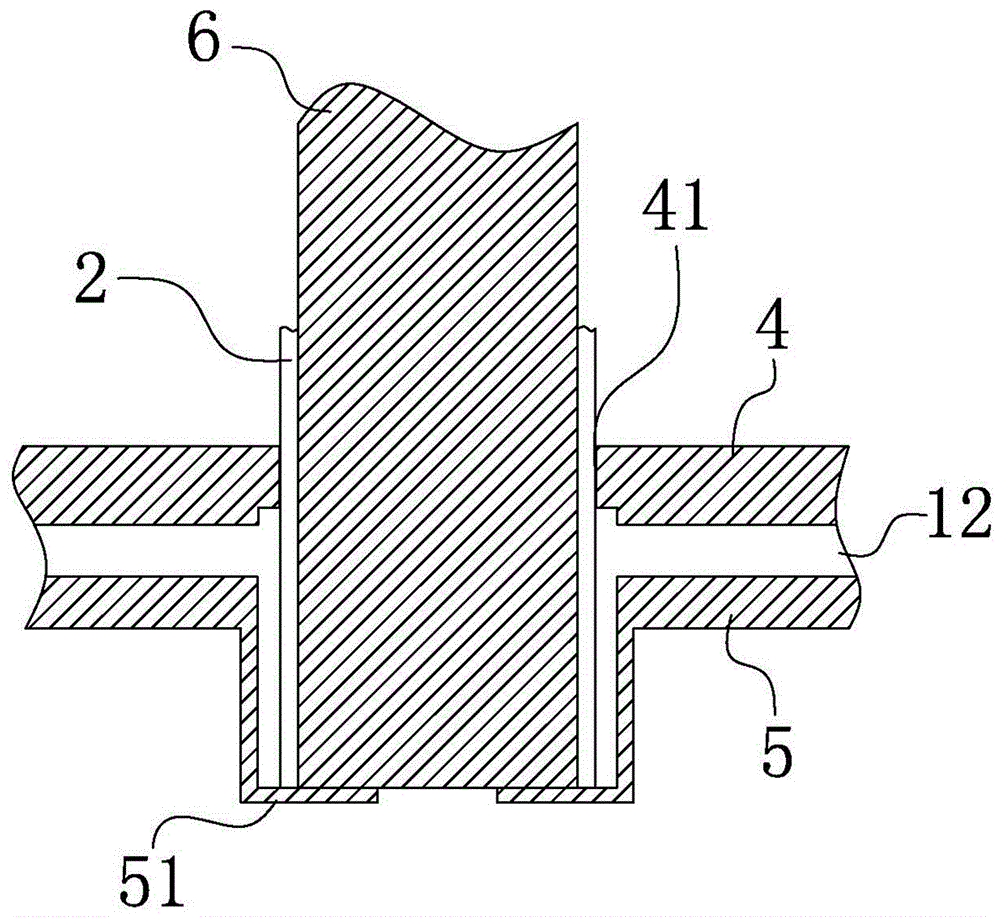

[0045] Example 2: Reference Figure 1~Figure 3 , a PTFE tube heat exchanger, the difference from Example 1 is: the wall thickness of the heat exchange tube 2 is 1.2 mm, and the tube sheet 1 includes an upper tube sheet 11 and a lower tube sheet 12, so The heat exchange tubes 2 are arranged between the upper tube sheet 11 and the lower tube sheet 12;

[0046] The heat exchange tube 2 and the upper tube sheet 11 are welded by an auxiliary tool;

[0047] The auxiliary tools include: a frame-shaped tube sheet expansion limiting mold 3;

[0048] A tube plate supporting tray 4, on which are provided with a plurality of position-limiting holes 41 corresponding to the tube holes;

[0049] A plurality of tube sheet expansion limiting rings 5, the tube sheet expansion limiting rings 5 are provided with heat exchange tube retaining rings 51;

[0050] A plurality of heat-conducting steel cores 6 adapted to the inner diameter of the heat exchange tube;

[0051] When welding, insert t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wall thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com