Fragrance self-restoration extrusion stage PP (polypropylene) composite material and preparation method thereof

A composite material and polypropylene technology, which is applied in the field of self-healing extrusion-grade polypropylene composite materials, can solve problems such as burnt smell of extrusion-grade polypropylene materials, and achieve the effect of improving the acceptability and reducing the amount of addition.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

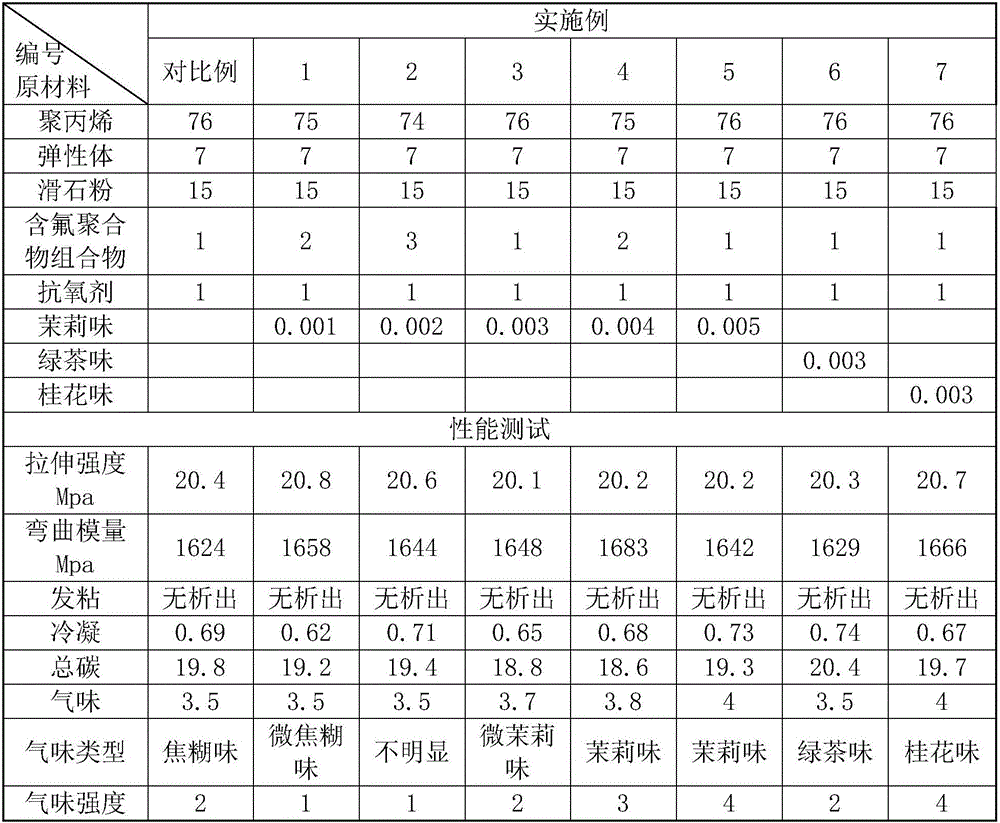

Embodiment 1~ Embodiment 5

[0027] Weigh the components shown in Table 1 by weight percentage: polypropylene, elastomer, talcum powder, fluoropolymer composition, antioxidant, jasmine flavoring agent. The polypropylene, elastomer, and fluoropolymer compositions were first mixed in a high mixer for 3 minutes, then added with talcum powder, jasmine flavoring agent, and antioxidant, and mixed for another 2 minutes, and the speed of the high mixer was 1500 rpm The premix was melted and extruded by a twin-screw extruder, and vacuum granulated to obtain a flavor-type, self-repairing extrusion-grade polypropylene composite material. The specific data are listed in Table 1.

Embodiment 6

[0029] Weigh the components shown in Table 1 by weight percentage: polypropylene, elastomer, talcum powder, fluoropolymer combination

Embodiment 7

[0031] Take the components shown in Table 1 by weight percentage: polypropylene, elastomer, talcum powder, fluoropolymer composition, antioxidant, sweet-scented osmanthus flavor flavoring agent, preparation method is the same as embodiment 1, performance test data is listed in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com