Light bridge crane guided by horizontal wheel opposite angles

A technology of bridge cranes and horizontal wheels, which is applied in the direction of walking bridge cranes, cranes, and traveling mechanisms, and can solve the problems of heavy weight, many links, and large space occupied by the operating mechanism.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

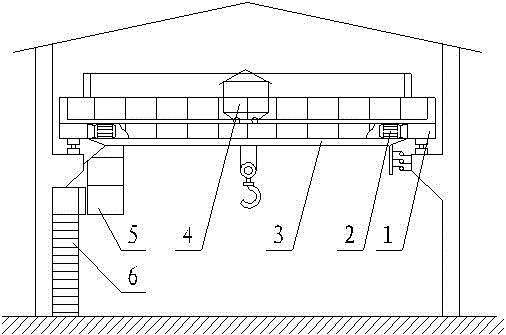

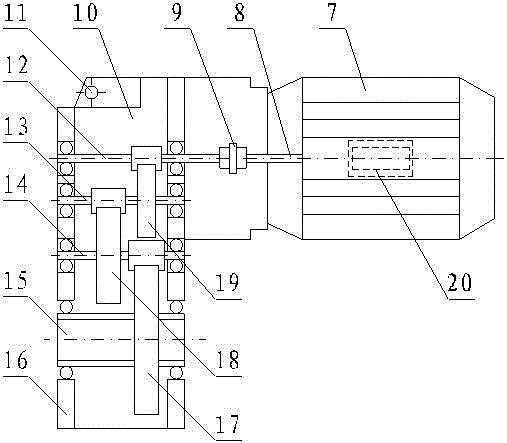

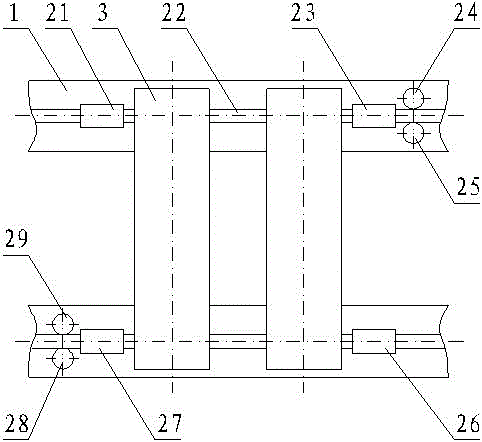

[0019] Such as figure 1 , figure 2 and image 3 As shown, a portable bridge crane with horizontal wheel diagonal guidance, it includes a main girder 3, the two ends of the main girder 3 are respectively connected with end beams 1, and the main girder 3 is close to the left end girder 1 A control room 5 is provided below the end beam 1, a ladder 6 is connected to the left side of the end beam 1, a lifting trolley 4 is provided on the upper side of the main beam 3, and large The cart running mechanism 2, the cart running mechanism 2 includes a motor 7, the lower end of the motor 7 is fixed on the main beam 3 through the motor support 20, the left end of the motor 7 is welded on the box body 10, the The box 10 is fixed on the main beam 3 through the moment support hole 11, the motor 7 is connected to the coupling 9 through the motor output shaft 8, and the coupling 9 is connected to the gear A19 through the gear shaft A12, so The gear A19 is connected to the gear B18 through ...

Embodiment 2

[0022] Such as figure 1 , figure 2 and image 3 As shown, a portable bridge crane with horizontal wheel diagonal guidance, it includes a main girder 3, the two ends of the main girder 3 are respectively connected with end beams 1, and the main girder 3 is close to the left end girder 1 A control room 5 is provided below the end beam 1, a ladder 6 is connected to the left side of the end beam 1, a lifting trolley 4 is provided on the upper side of the main beam 3, and large The cart running mechanism 2, the cart running mechanism 2 includes a motor 7, the lower end of the motor 7 is fixed on the main beam 3 through the motor support 20, the left end of the motor 7 is welded on the box body 10, the The box 10 is fixed on the main beam 3 through the moment support hole 11, the motor 7 is connected to the coupling 9 through the motor output shaft 8, and the coupling 9 is connected to the gear A19 through the gear shaft A12, so The gear A19 is connected to the gear B18 through ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com